Thrust load applying mechanism, and disk device having thrust load applying mechanism

A pressure mechanism and thrust load technology, which is applied in data recording, instrumentation, information storage, etc., can solve the problems that hinder the smooth operation of the optical pickup moving mechanism, achieve smooth operation, reduce the influence of motor cogging, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Preferred embodiments of the disk device of the present invention will be described below with reference to the accompanying drawings.

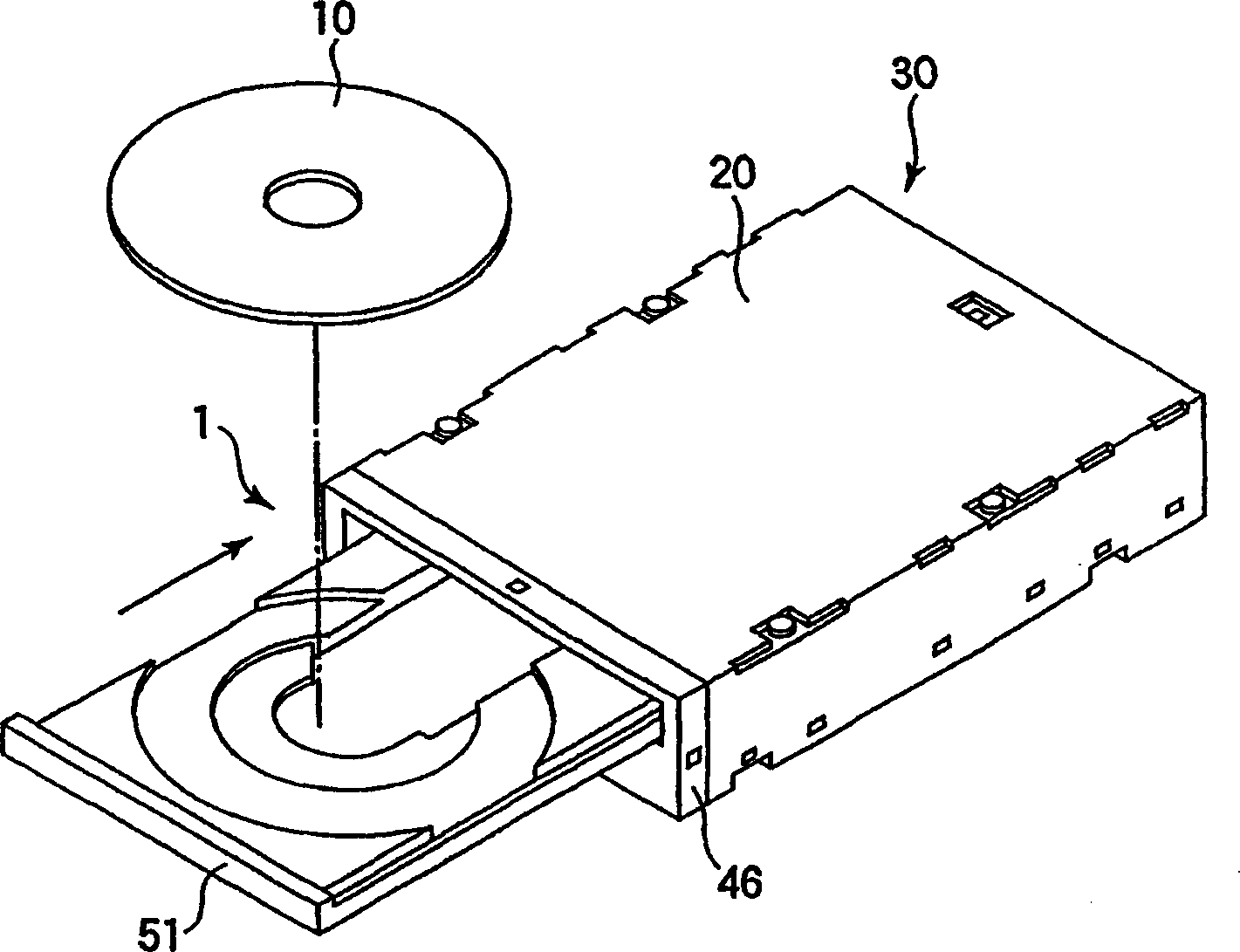

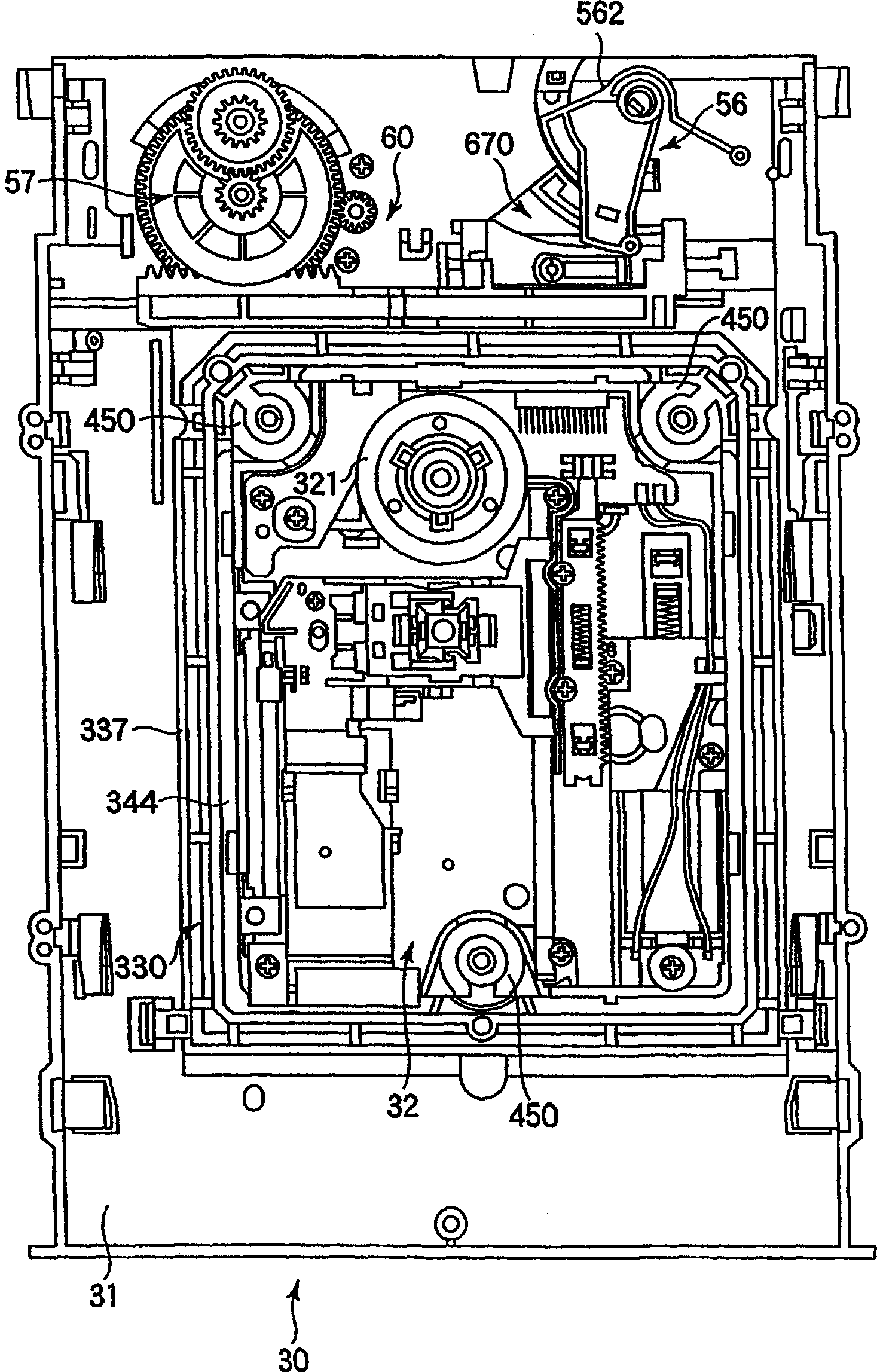

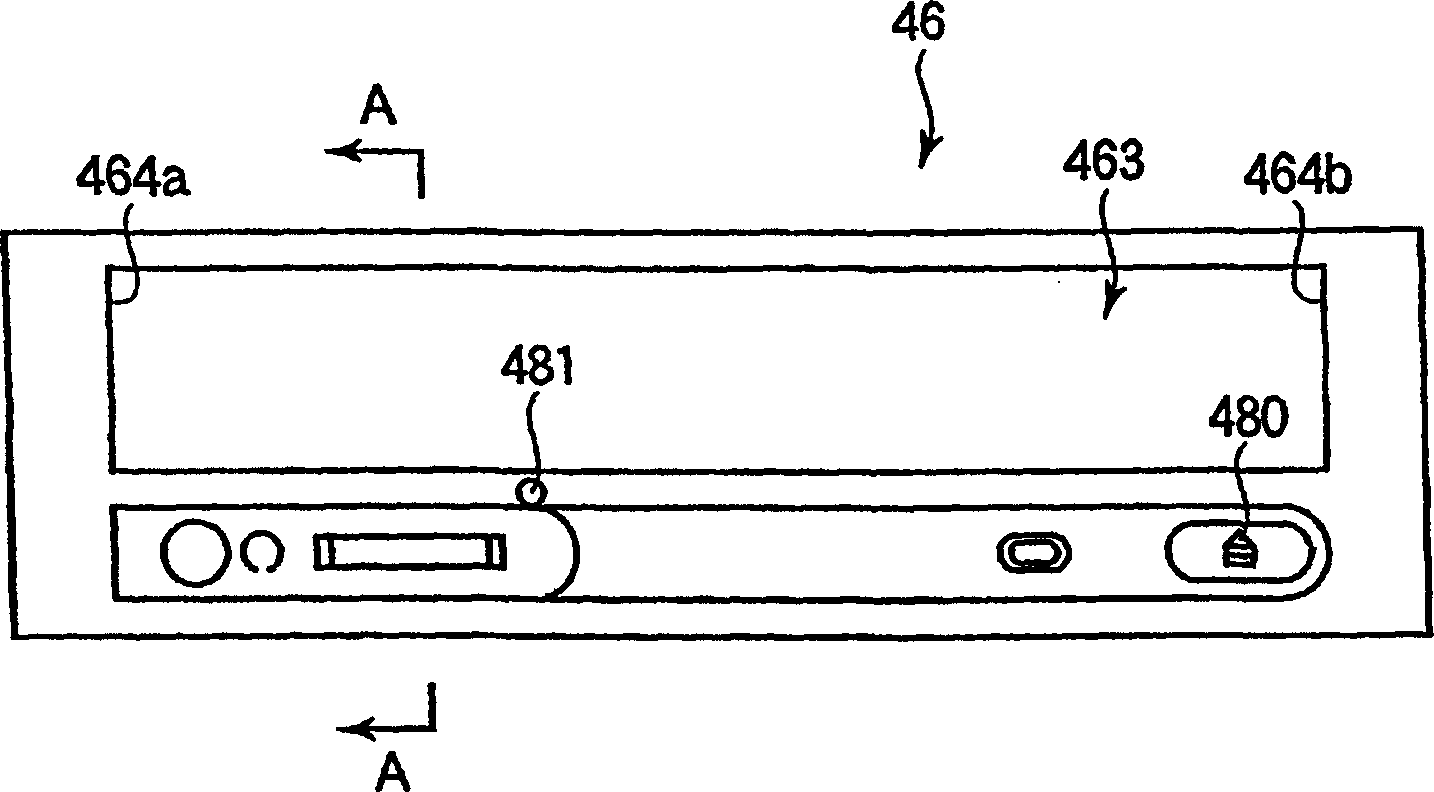

[0074] figure 1 is a perspective view showing the overall structure of the disk device of the present invention, figure 2 is a plan view of the main body of the disk drive.

[0075] Such as figure 1 As shown, the disc device 1 is an optical disc device for reproducing, recording, and reproducing discs 10 such as CDs and DVDs, and consists of a device main body 30 housed in a case 20 (refer to figure 2 ) and a disc tray 51 for transporting the disc 10 that moves in the front-rear direction (horizontal direction) relative to the apparatus main body 30.

[0076] Such as figure 2 As shown, the device main body 30 has a printed circuit board (not shown) and a frame 31 provided on the printed circuit board. As described above, the device main body 30 is accommodated in the case 20 formed of a thin metal plate.

[0077] The printed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com