Tea microwave de-enzyming process and apparatus

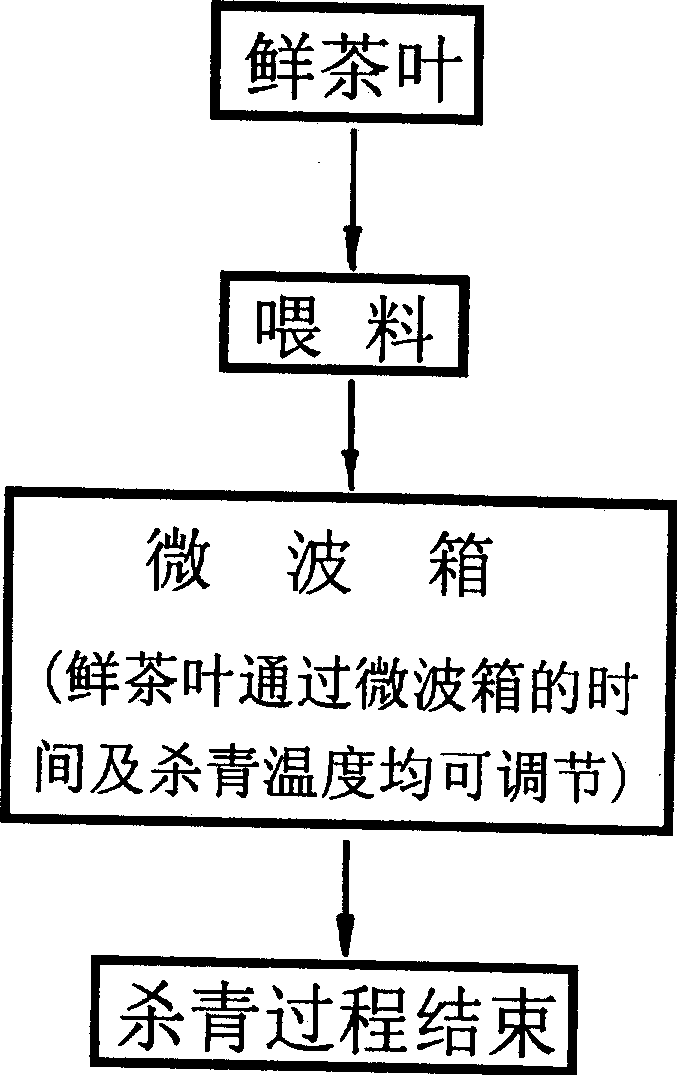

A technology for curing green tea and tea by microwave is applied in lighting and heating equipment, food processing, tea processing before extraction, etc. It can solve the problems of high energy consumption, high technical requirements, uneven greening of tea leaves, etc. , the effect of high ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described through the embodiments below with reference to the accompanying drawings.

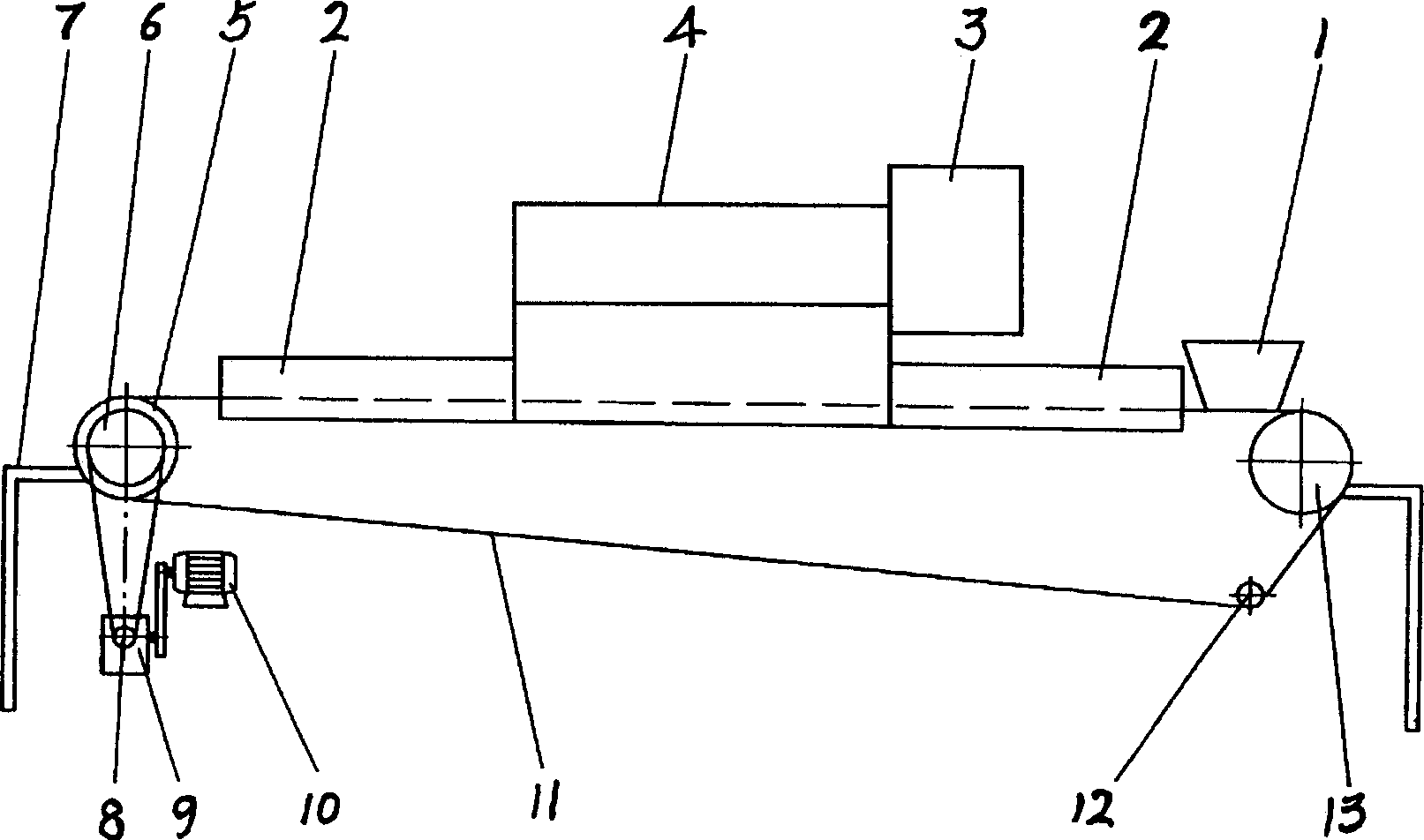

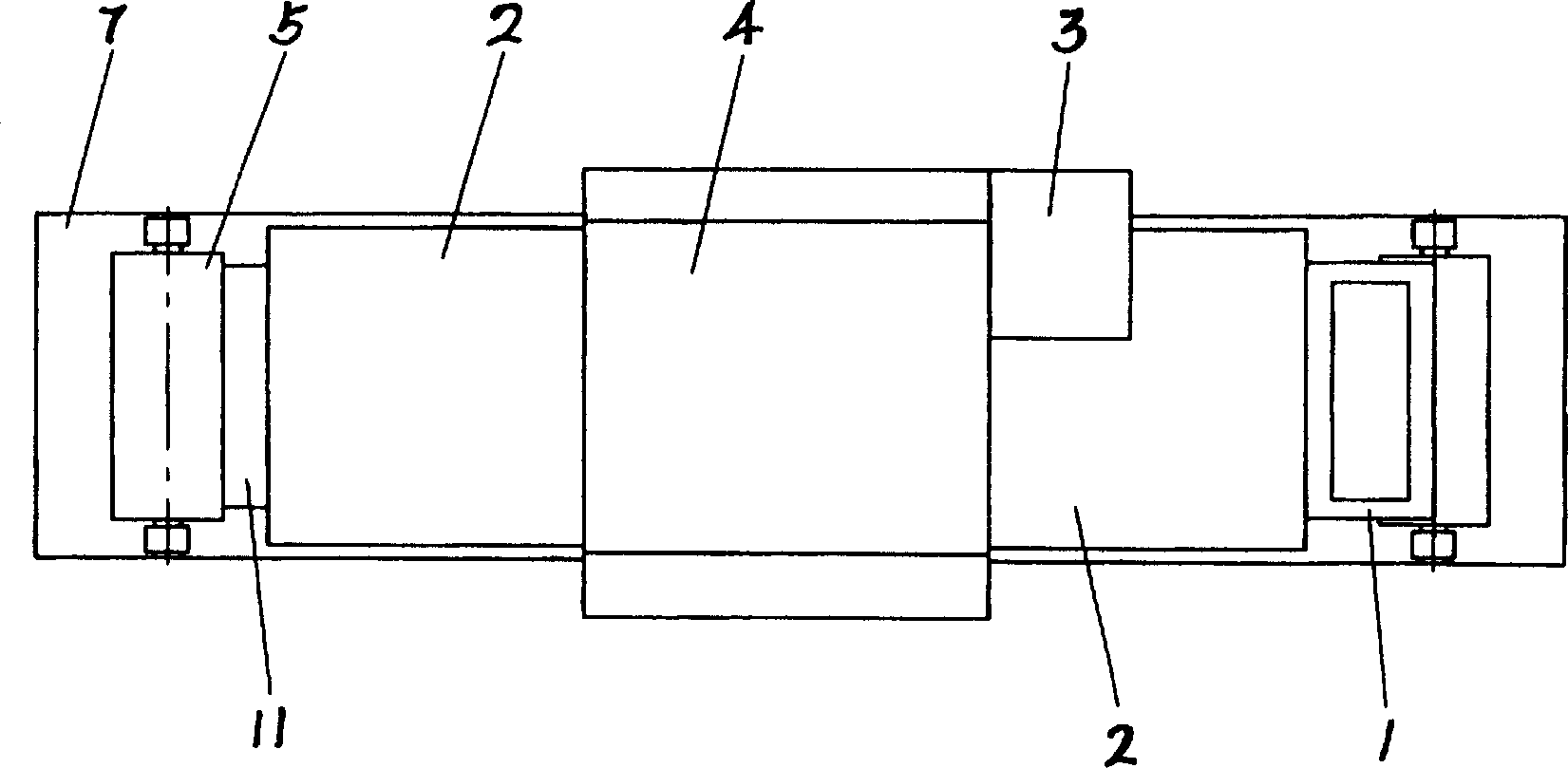

[0012] Refer to attached figure 1 And attached figure 2 A set of microwave greening equipment for tea includes a tea feeding port, an electrical control box (3), a microwave box (4), a frame (7) and a tea delivery device. The tea delivery device is composed of a conveyor belt (11), a conveyor belt shaft A (5), a conveyor belt shaft B (12), a conveyor belt shaft C (13), a sprocket transmission mechanism, a speed changer (9) and a motor (10) . The conveyor belt (11) is made of cotton cloth, and it is respectively wound on the conveyor belt rotating shaft A (5), the conveyor belt rotating shaft B (12) and the conveyor belt rotating shaft C (13), wherein the conveyor belt rotating shaft B (12) is arranged on the tea leaves The head of microwave cleaning equipment frame (7), conveyor belt rotating shaft A (5) is located at the afterbody of frame (7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com