Capacitor and manufacturing method

A manufacturing method and capacitor technology, which are applied in the directions of multilayer capacitors, fixed capacitor electrodes, fixed capacitor dielectrics, etc., to achieve the effect of reducing stress concentration

Inactive Publication Date: 2003-12-31

PANASONIC CORP

View PDF1 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, especially when the upper electrodes 116, 116A, 116B and the lower electrodes 112 are formed by vapor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Login to View More

Abstract

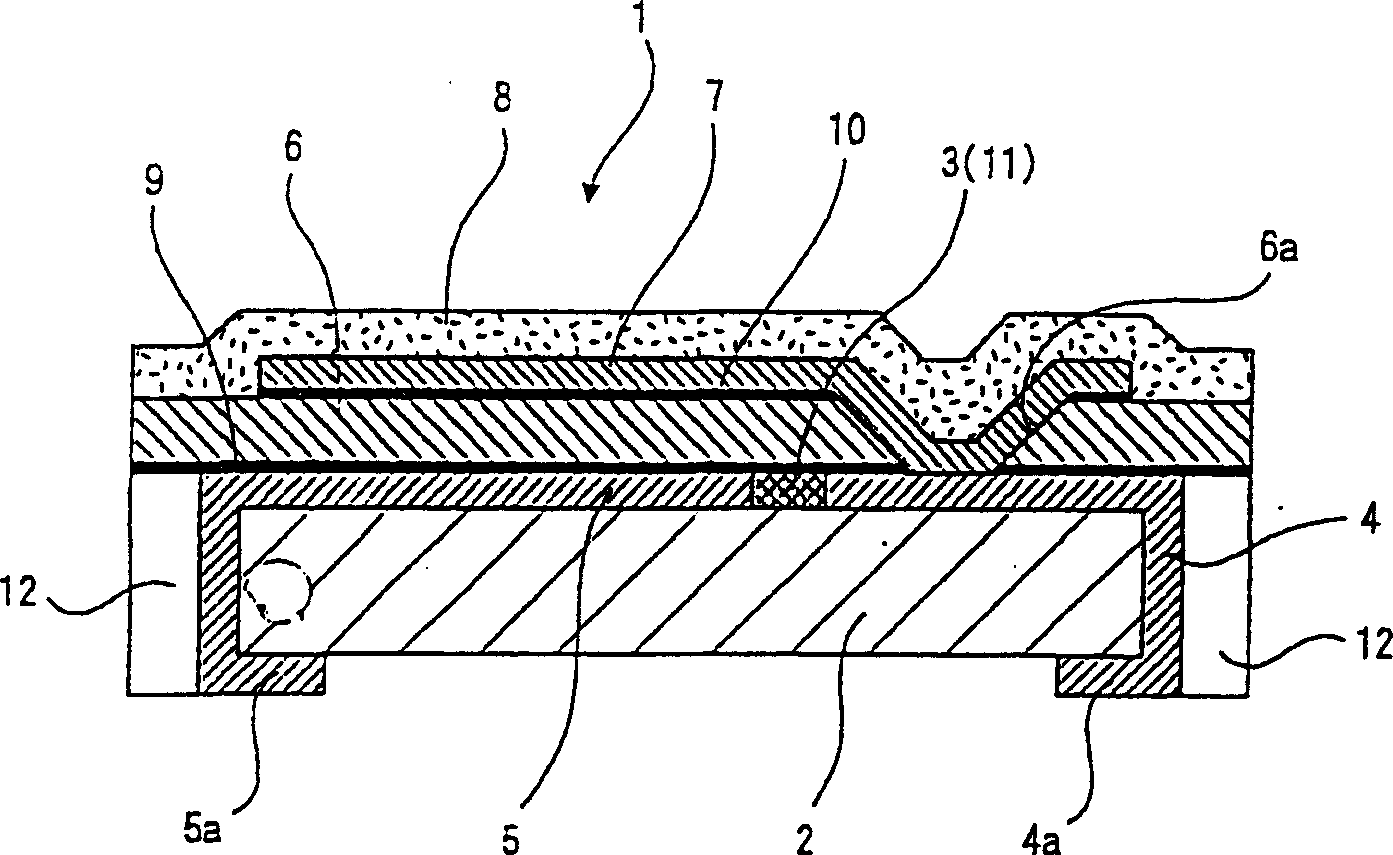

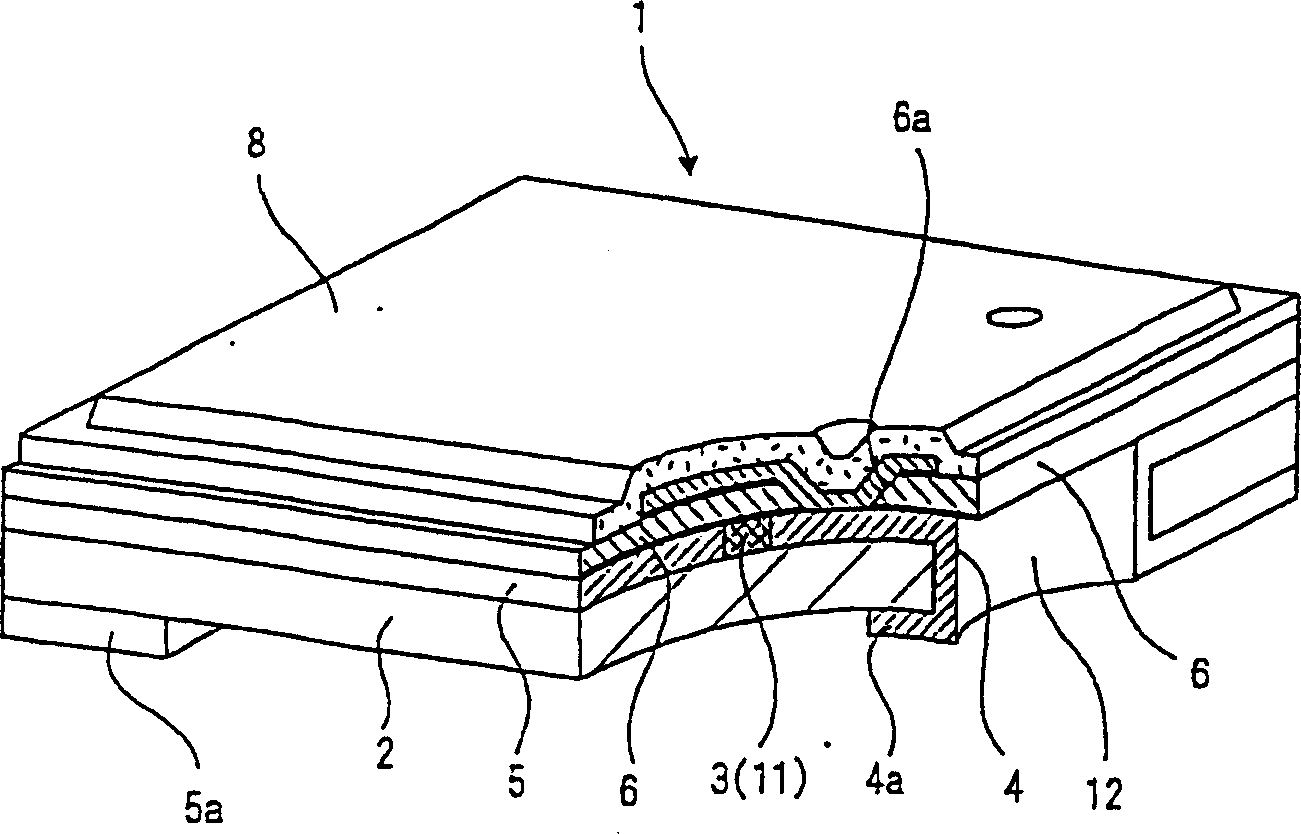

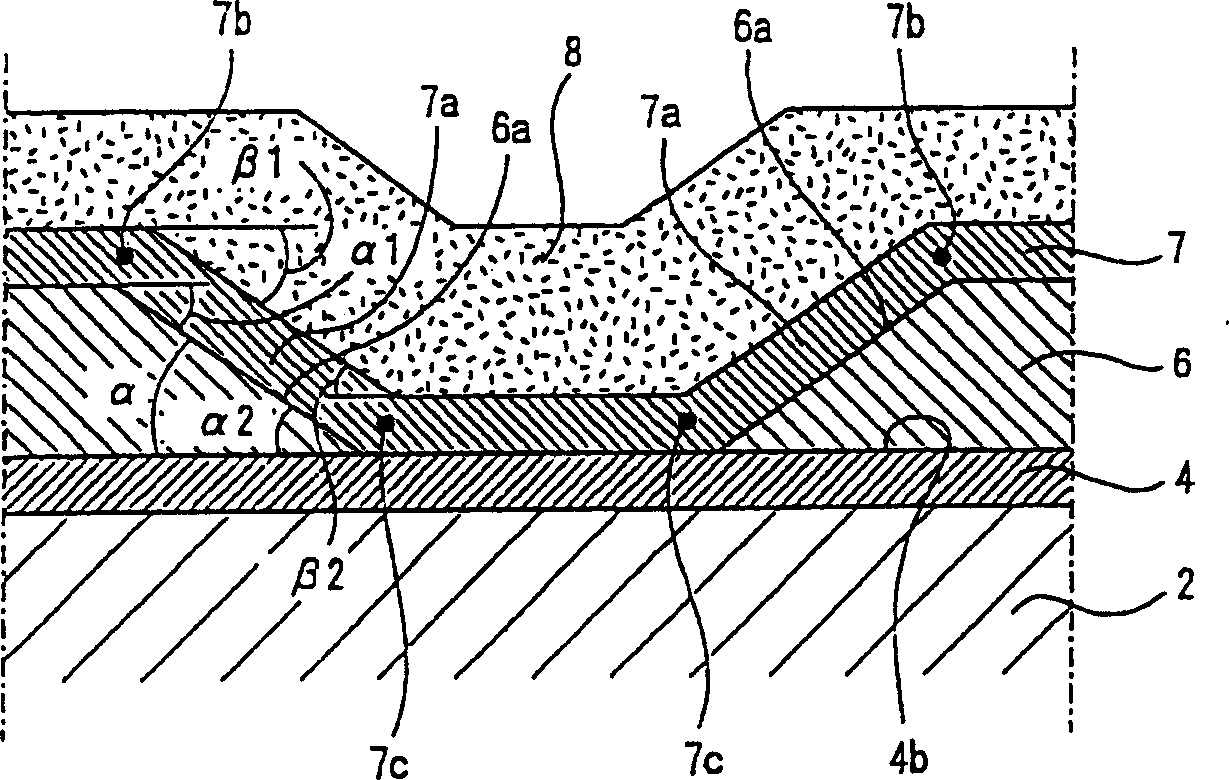

A capacitor (1) using a flexible substrate (2) includes a hole portion (6a) formed in a dielectric (6) to connect an upper electrode (7) to an external leader electrode (4). At least part of the hole portion ( 6a) extends from its lower end to upper end at an inclination between 0.1 and 20 DEG with respect to a top surface of the external leader electrode (4). Then, an upper end corner of an inclined wall surface of the upper electrode (7), which inclines along the hole portion (6a) of the dielectric (6), has a downward inclination between 0.1 and 20 DEG . A lower end corner of the inclined wall surface of the upper electrode (7), which inclines along the hole portion of the dielectric (6), has an upward inclination between 0.1 and 20 DEG . As a result, stress concentration on the corners of the upper electrode (7) is drastically reduced to prevent the upper electrode (7) from cracking.

Description

technical field [0001] The present invention relates to capacitors and methods for their manufacture. Background technique [0002] As a conventional small capacitor, it is known that an electrode portion composed of a thin-film dielectric layer and a metal film is formed on a relatively rigid substrate such as ceramics or epoxy resin. However, for such a capacitor, although the thin film dielectric layer or the electrode part can be made very thin, if the substrate does not have a certain thickness (for example, 0.5mm), there is a risk of cracking and damage. Thinness has a certain limit, and it is difficult to use such capacitors for products that are not even 1mm thick. [0003] As a capacitor that meets this requirement, for example, disclosed in Japanese Patent Laid-Open No. 11-97287, there is a film-shaped flexible capacitor composed of a highly flexible organic resin substrate such as polyimide with a thickness of less than 0.1 mm. substrate capacitors. According t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01G4/005H01G4/06H01G4/33

CPCH01G4/33C22C38/14H01G4/005C22C38/002B22F9/007H01F1/0574C22C38/005C22C38/12B22F9/008H01G4/06B22F2999/00H01F1/0579H01F1/058B82Y25/00C22C1/0441

Inventor 渡边久芳今中崇内田徹仙石修糸井真介西原宗和東田隆亮末次大輔山本憲一勝部淳久村博隆

Owner PANASONIC CORP

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com