Rock screw breaking-resisting coal bunker

An anti-breakage and rock-proof technology, applied in the field of coal storage bunkers, can solve the problems of high maintenance costs, easy breakage of lump coal, high transportation and storage costs, etc., and achieve the effects of simple construction and maintenance, reduction of lump coal breakage, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

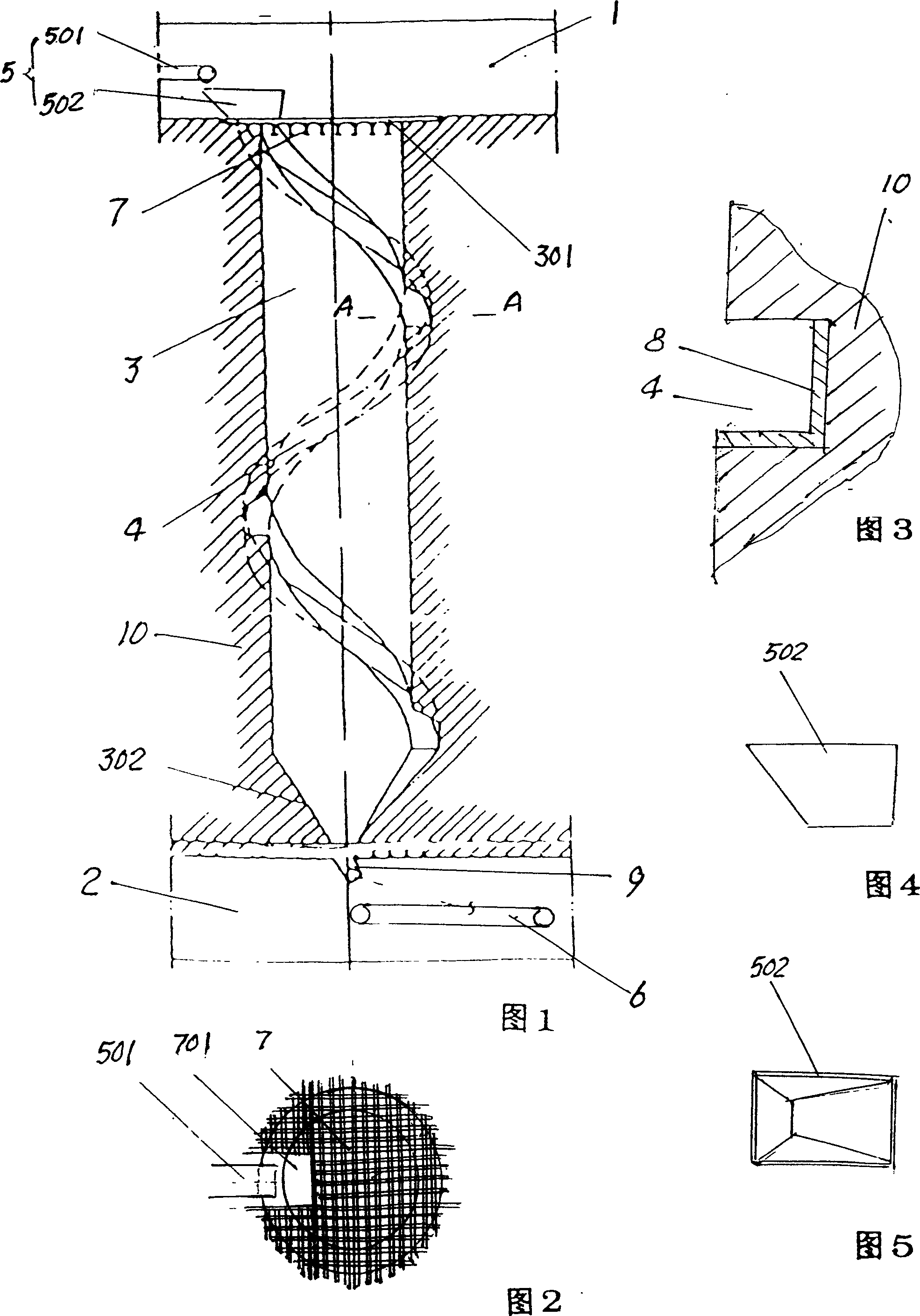

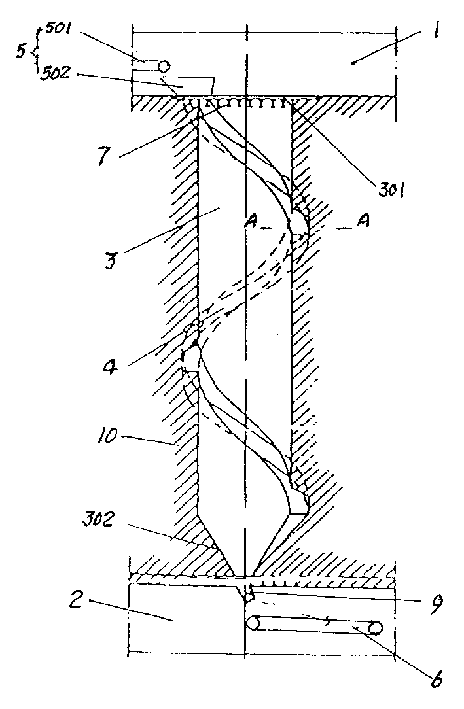

[0036] Please refer to Fig. 1 and Fig. 2, the present invention is a kind of rock spiral anti-breakage coal bunker, including inlet guide device and coal feeder, characterized in that: on the rock 10 between the upper and lower roadways 1 and 2 A vertical cylindrical warehouse body 3 is provided, the upper end round hole 301 of the warehouse body 3 is provided with a sealing grate 7 with an inlet hole, the lower end of the warehouse body 3 is provided with a tapered hole 302, and the outlet at the bottom of the cone hole is equipped with a feeder. Coal machine 9, the coal feeder has a spiral groove 4 recessed into the wall on the inner wall of the cylindrical rock of the bin body 3, and the upper part of the spiral groove communicates with the entrance 701 of the sealing grate 7 installed on the round hole 301, The bottom of the spiral groove leads to the entrance of the coal feeder 9, and the entrance guide device 5 is housed in the upper roadway.

[0037] The inlet guide dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com