Surface wave apparatus

A surface wave device and surface wave technology, applied in impedance networks, electrical components, etc., can solve the problems of cracks or fragments in piezoelectric substrates, increase costs, and increase the size of surface wave devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

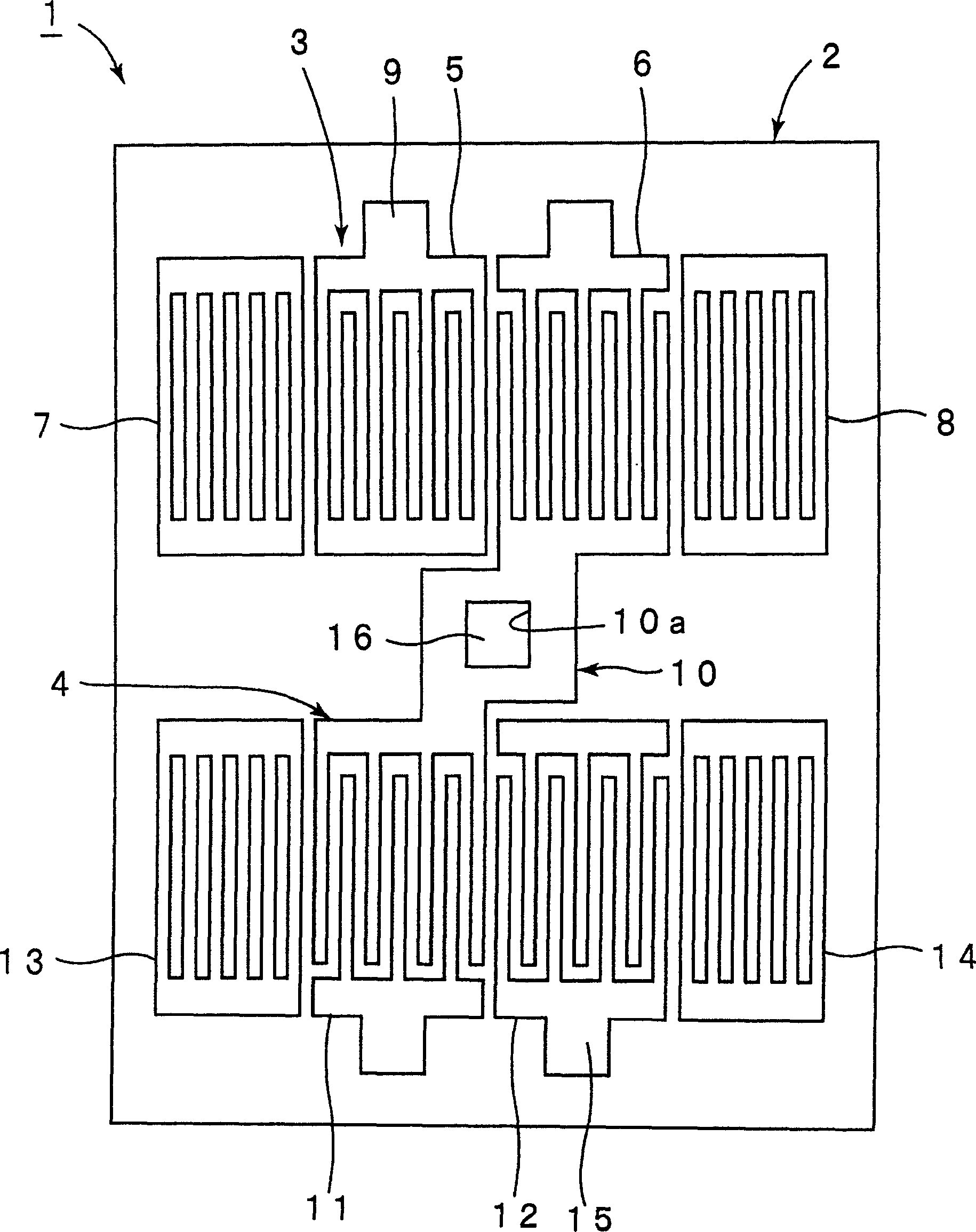

Image

Examples

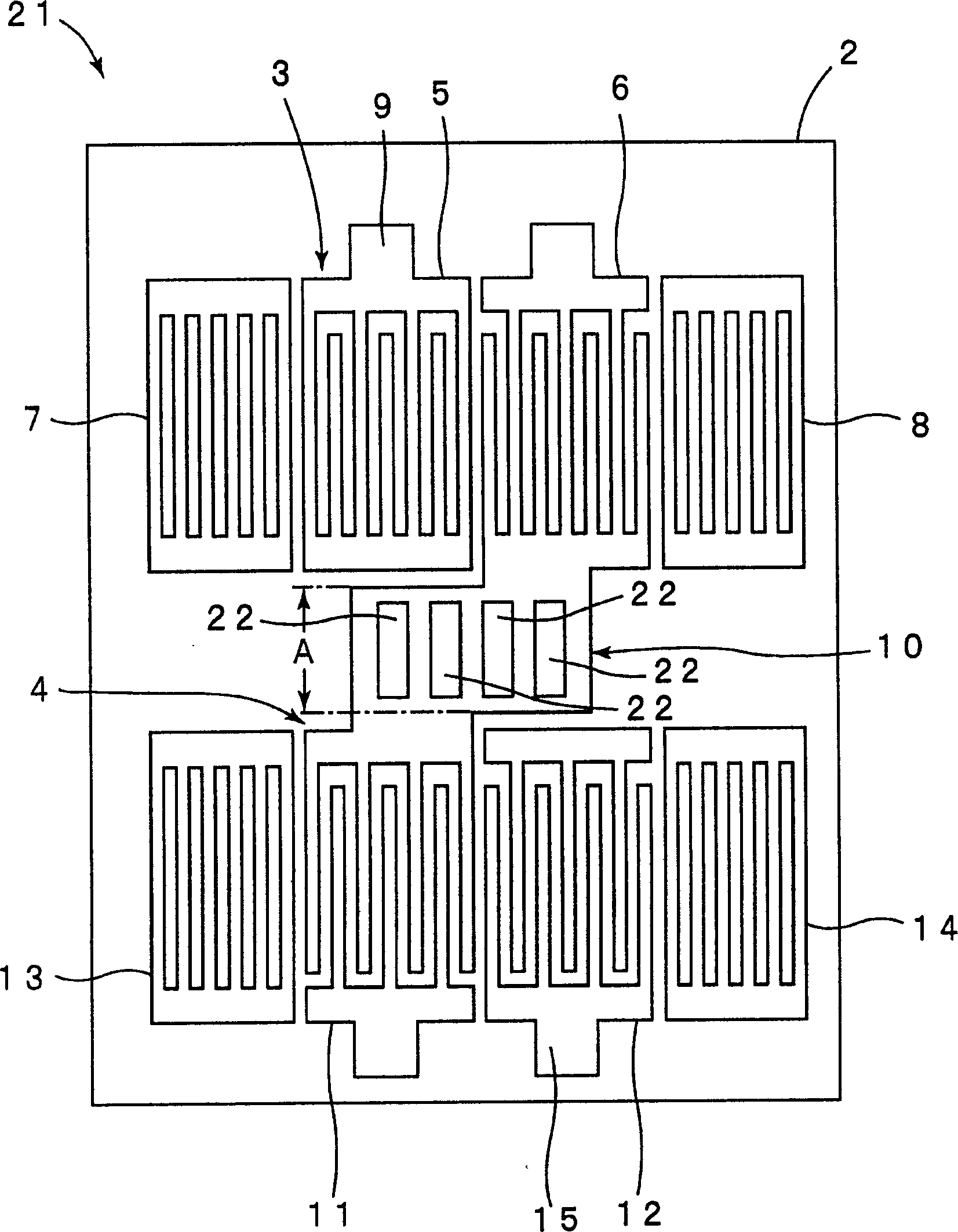

Embodiment 2

[0053] In the surface wave device 21 of the second embodiment, a plurality of elongated slits 22 serving as through-holes are formed in the inter-segment connection portion 10 . A free surface section is formed in this gap 22 . In this embodiment, the longitudinal direction of the slit 22 is a direction perpendicular to the surface wave propagation direction of the first and second surface wave filter elements 3 and 4 .

[0054] Thus, in the present invention, the slit 22 having the longitudinal direction may be provided as the through-hole constituting the free surface portion.

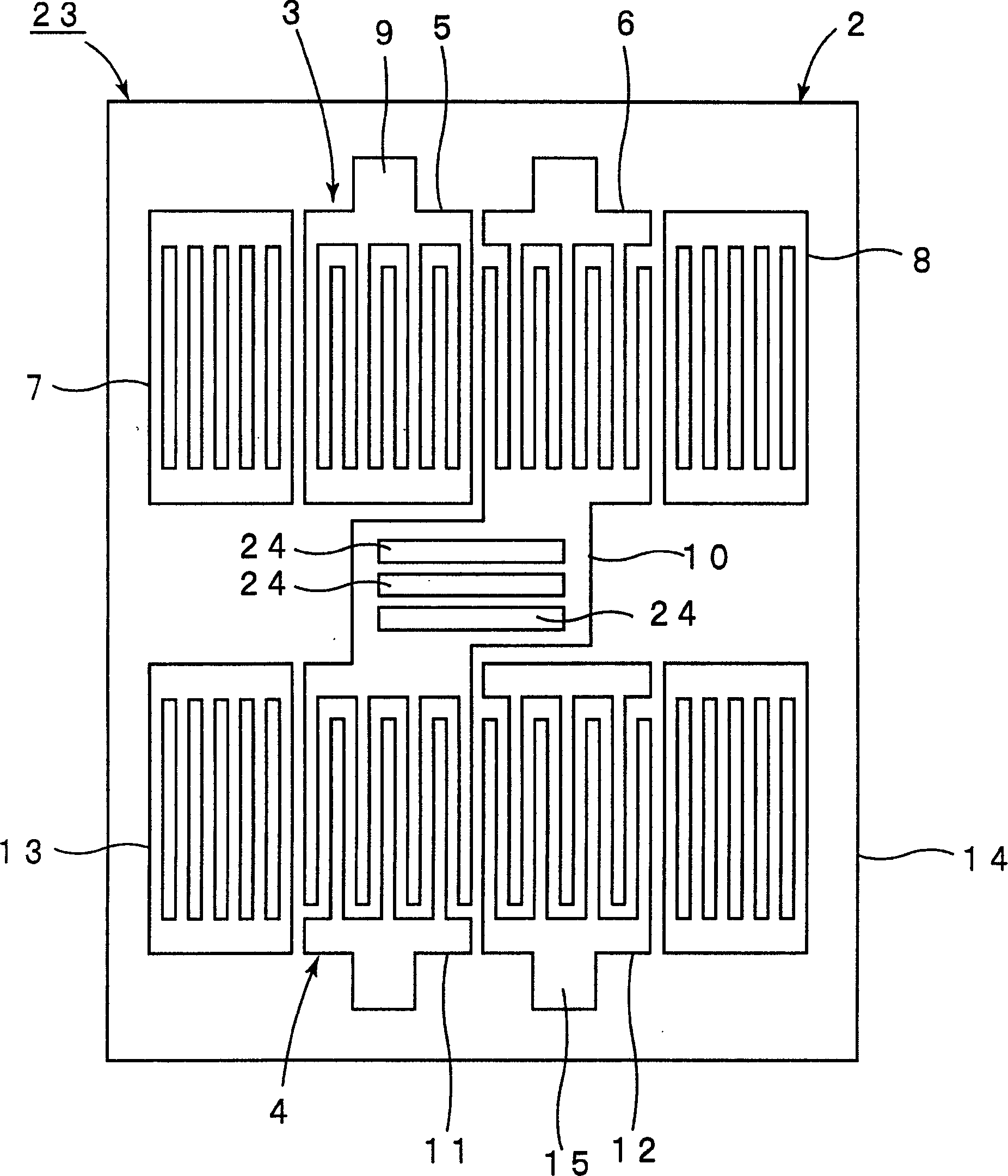

[0055] image 3 It is a plan view showing a surface wave device according to a modified example of the second embodiment. exist figure 2 In the shown surface wave device 21, a plurality of slits 21 are formed to extend in a direction perpendicular to the surface wave propagation direction of the surface wave filter elements 3, 4, but as image 3 Like the surface wave device 23 shown, the plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com