Creeping soft tube pump

A hose pump, hose technology, used in pumps, machines/engines, pumps with flexible working elements, etc., can solve problems such as restoring force attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

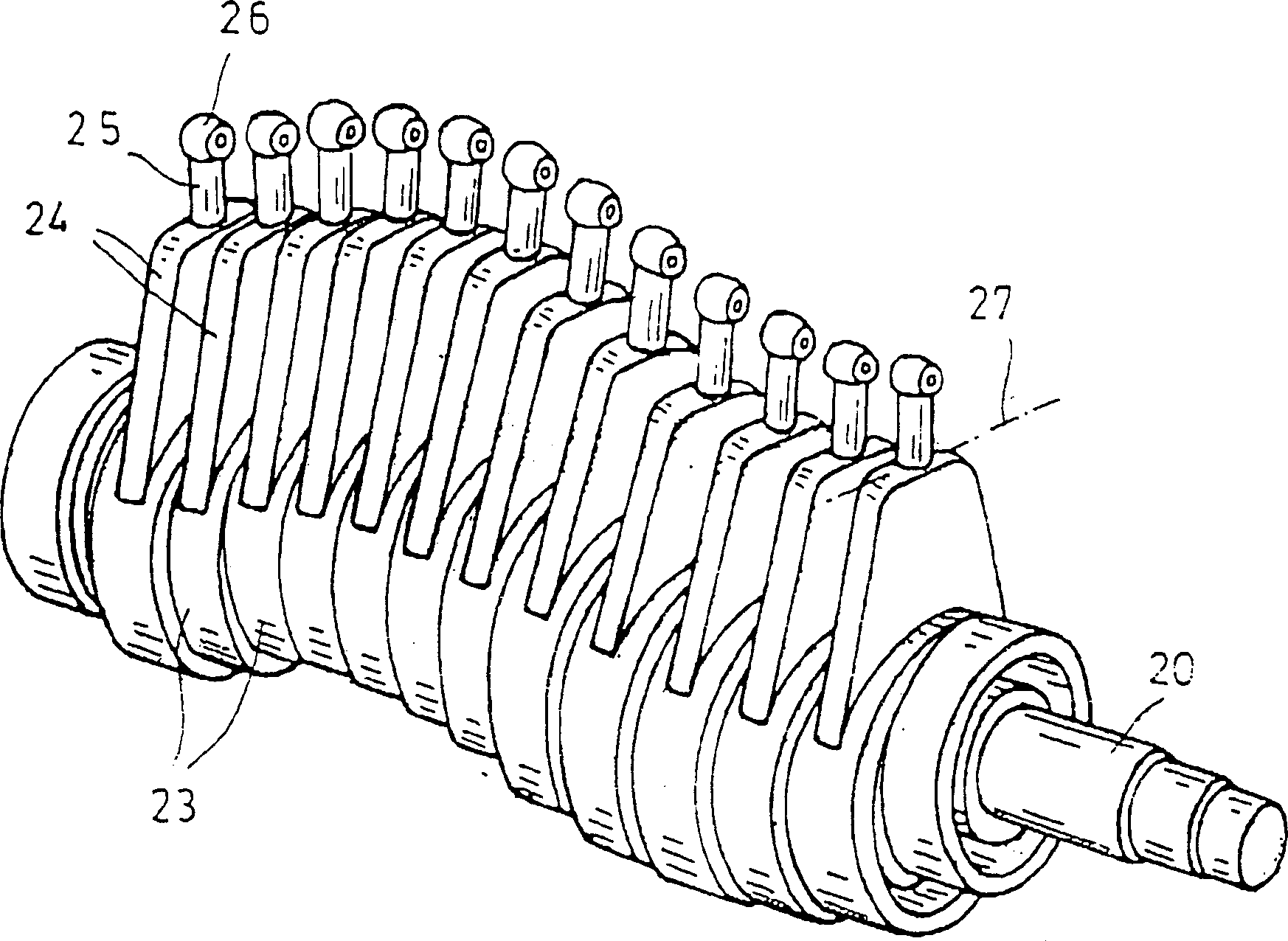

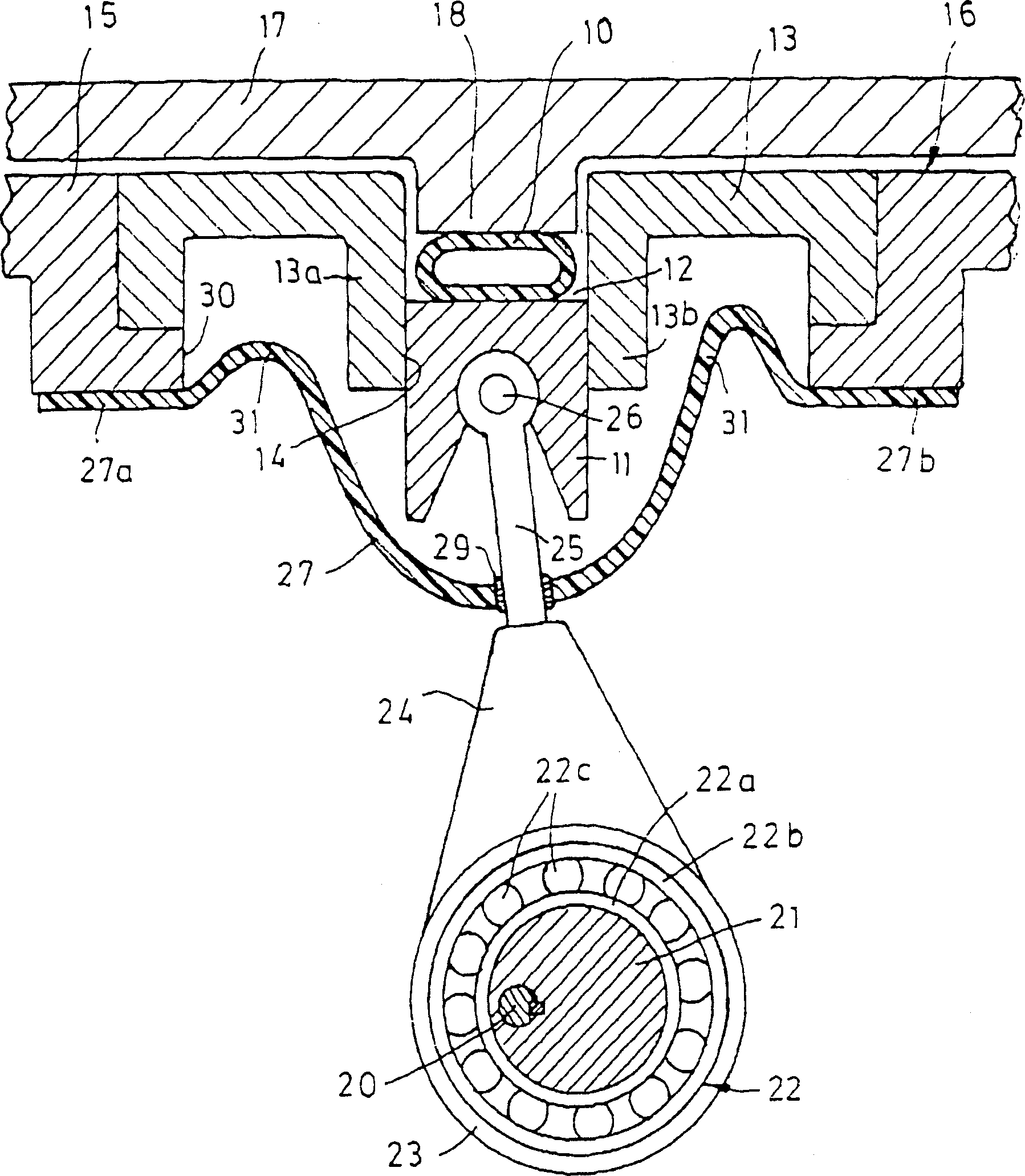

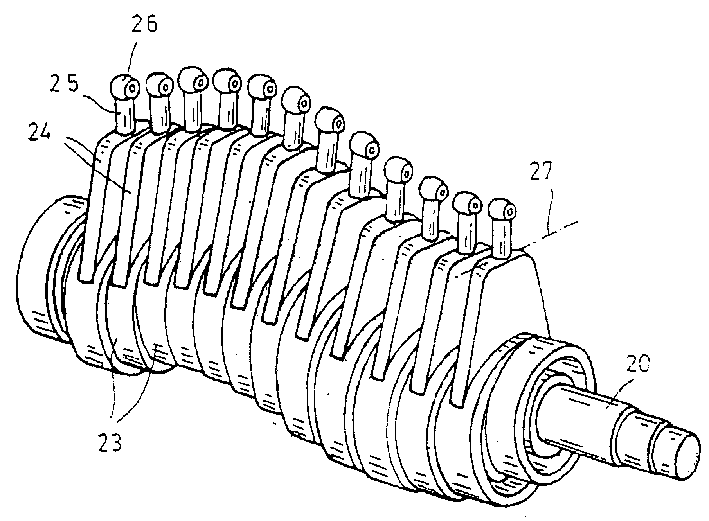

[0013] The hose pump shown in the figure comprises a pump hose 10 in which the liquid to be pumped is carried. This hose is continuously, periodically compressed and released by the fingers 11 of a plurality of pumps, as described in European Patent 0 214 443 .

[0014] The pump hose 10 is accommodated in an accommodation passage 12 formed in the guide plate 13 . The guide plate 13 has parallel walls 13a, 13b laterally forming the receiving channel 12 . The receiving channel 12 is connected to a plurality of guide grooves 14, in each of which a finger 11 of a pump is guided transversely in the direction of the hose. The guide plate 13 is attached to the front wall 15 of the pump housing 16 . The pump housing has a dour attached to its front, which forms a thrust bearing 17 for supporting the pump hose 10 . The thrust bearing 17 has a projection 18 protruding into the receiving channel 12 .

[0015] There are about twelve pump fingers 11 in total, which are driven sinusoida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com