Antiwear structure for preventing wankle compressor

A technology for compressors and sealing components, applied to mechanical equipment, machines/engines, rotary piston machines, etc., can solve the problems of refrigerant leakage pressure, noise generation, performance reduction of Wankel compressor 1, etc., to improve effect, the effect of avoiding pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

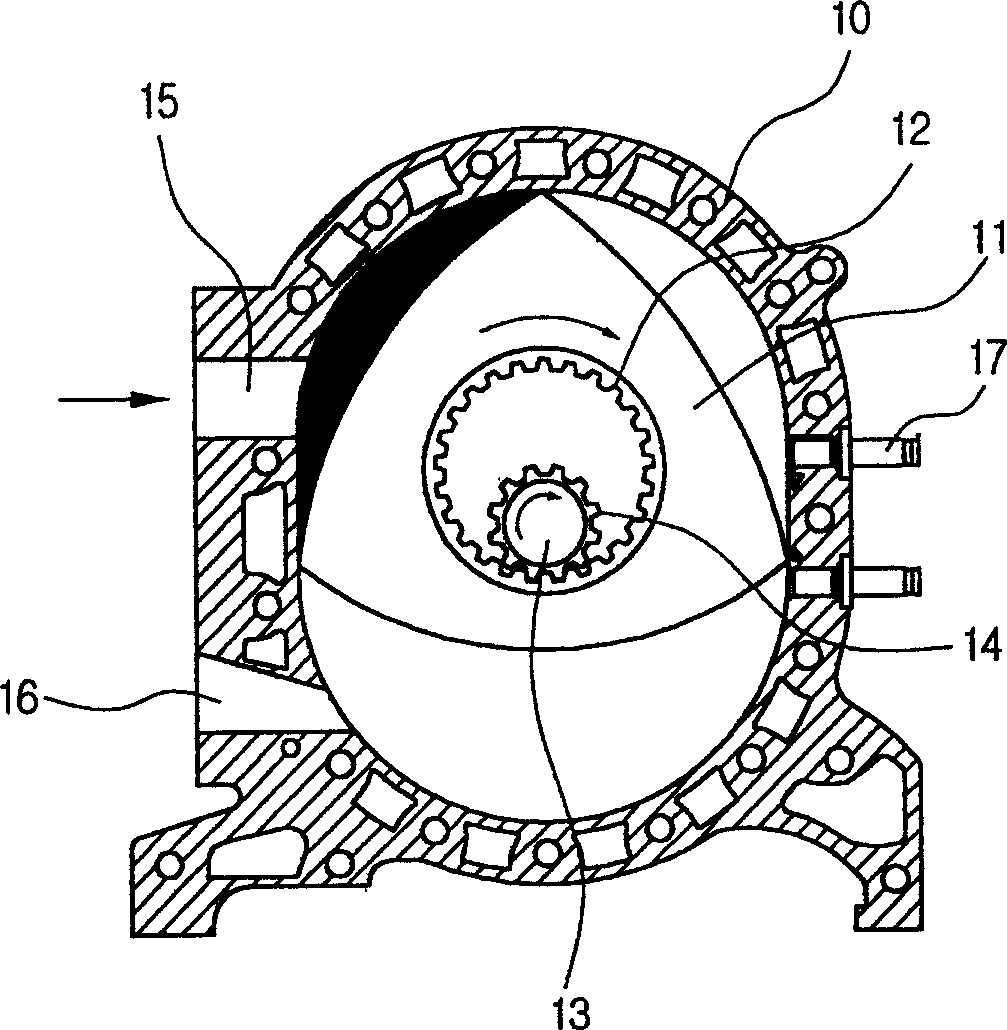

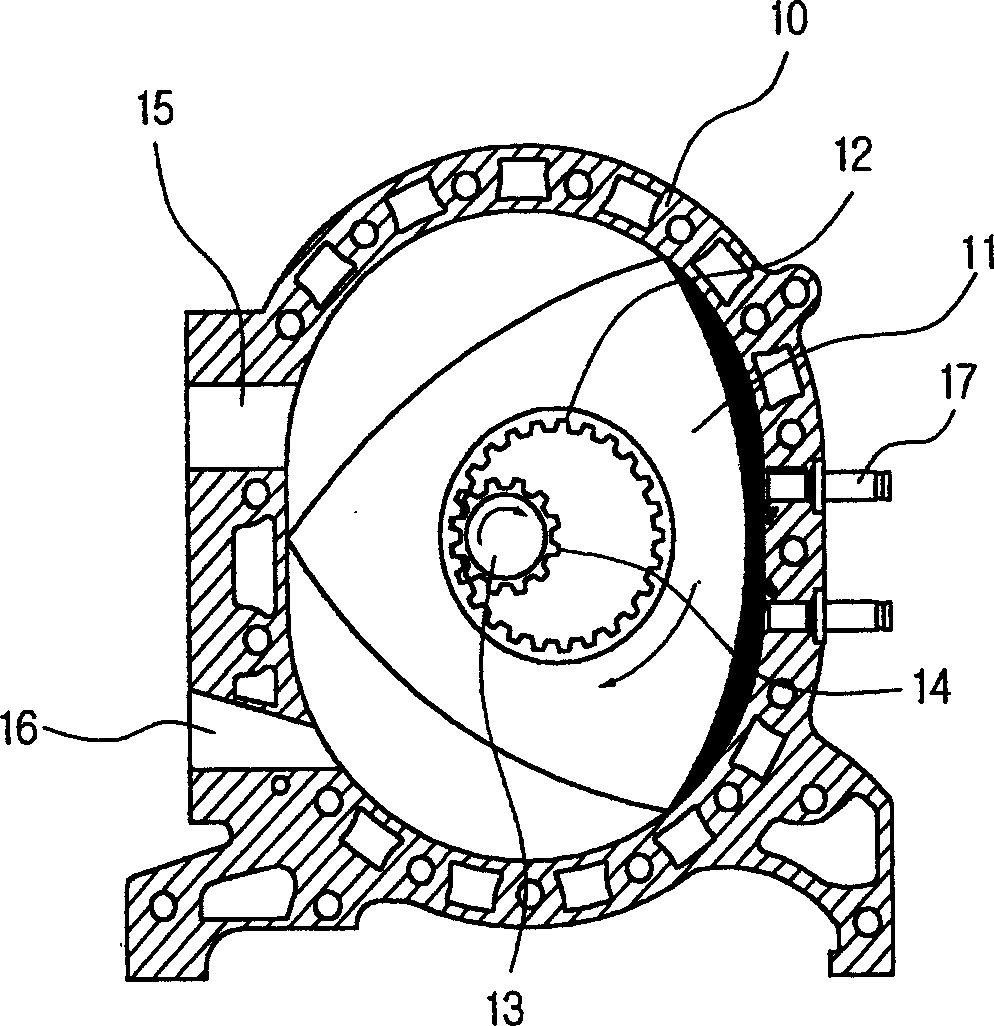

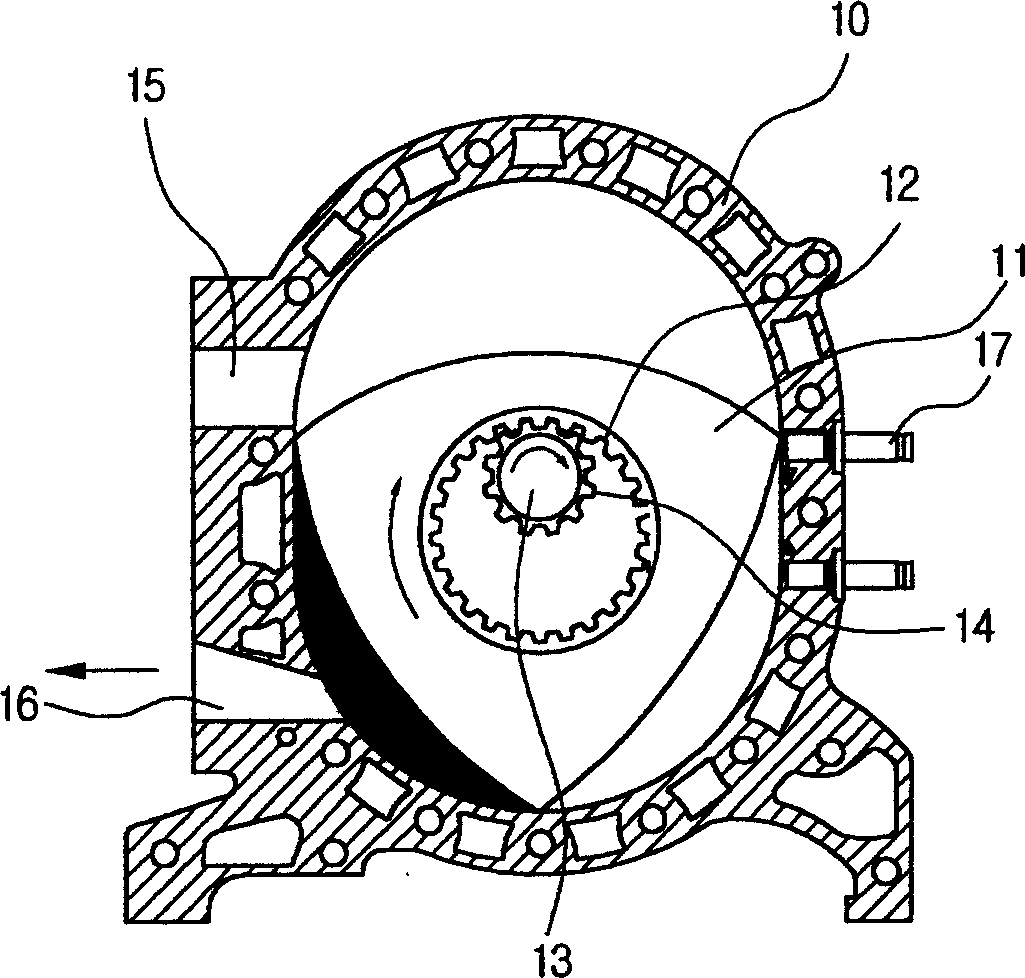

[0020] Such as Figure 4 As shown, the structure for preventing wear of the Wankel compressor 1a of the present invention changes the volume of the space in the cylinder through the eccentric movement of the triangular rotor 11, and realizes the process of sucking, compressing and outputting refrigerant when the rotor 11 rotates. In order to prevent wear and pressure loss of the rotor 11 and the inner wall of the cylinder 10 due to friction between the rotor 11 and the inner wall of the cylinder 10, an elastic sealing member 20 is installed at a certain position on the corner of the triangular rotor 11.

[0021] The structure for preventing the wear of the Wankel compressor is described in detail below:

[0022] The structure for preventing Wankel type compressor 1a wear of the present invention is to prevent the wear caused by the friction between the rotor 11 and the inner wall of the cylinder 10, and the gap caused by the wear will cause refrigerant leakage and pressure los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com