Method and apparatus for mfg. colour selecting electrode of colour CRT

A technology for cathode ray tubes and manufacturing devices, which is applied in the direction of non-luminescent electrode manufacturing and measurement/testing in the manufacturing process, and can solve problems such as complexity and large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

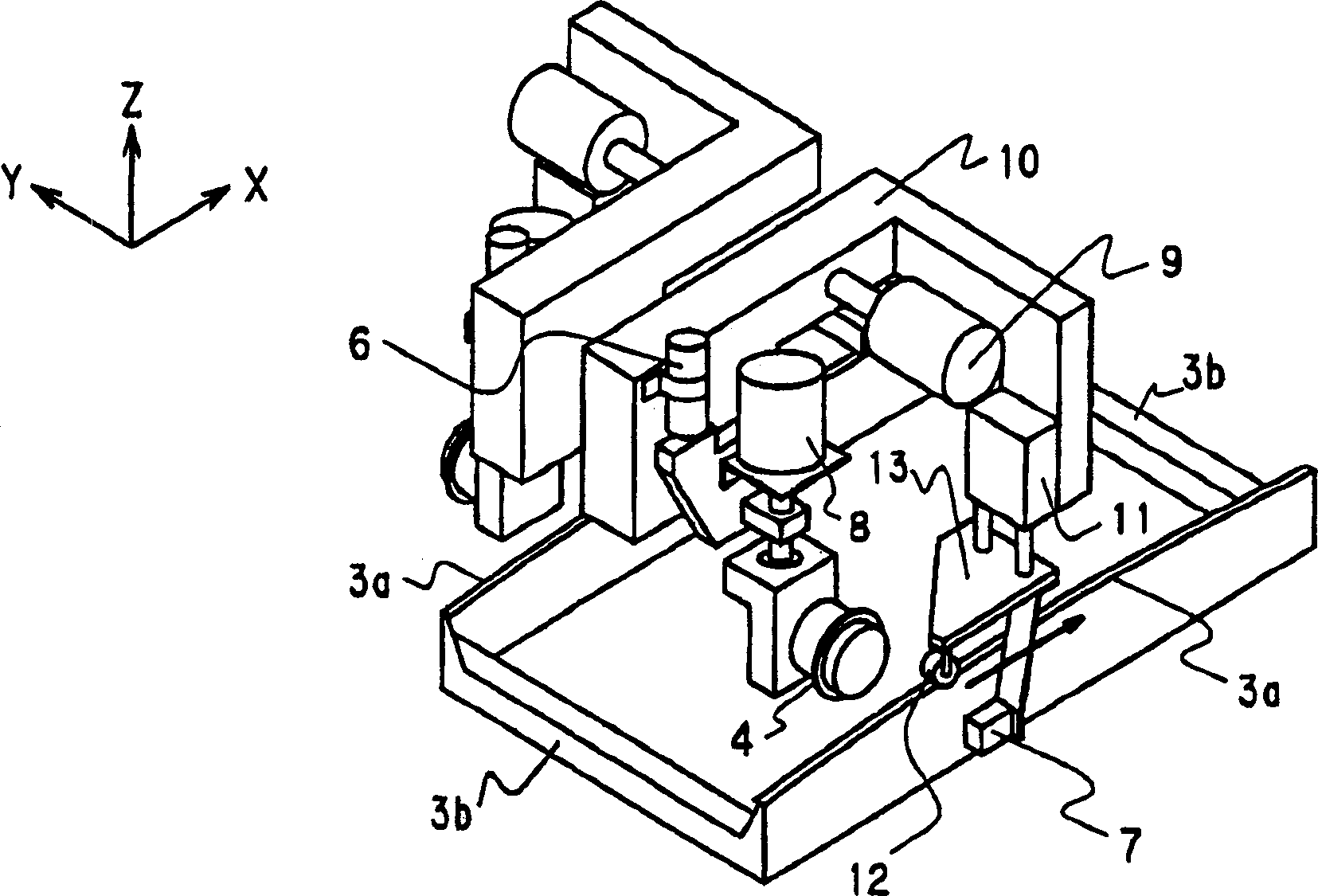

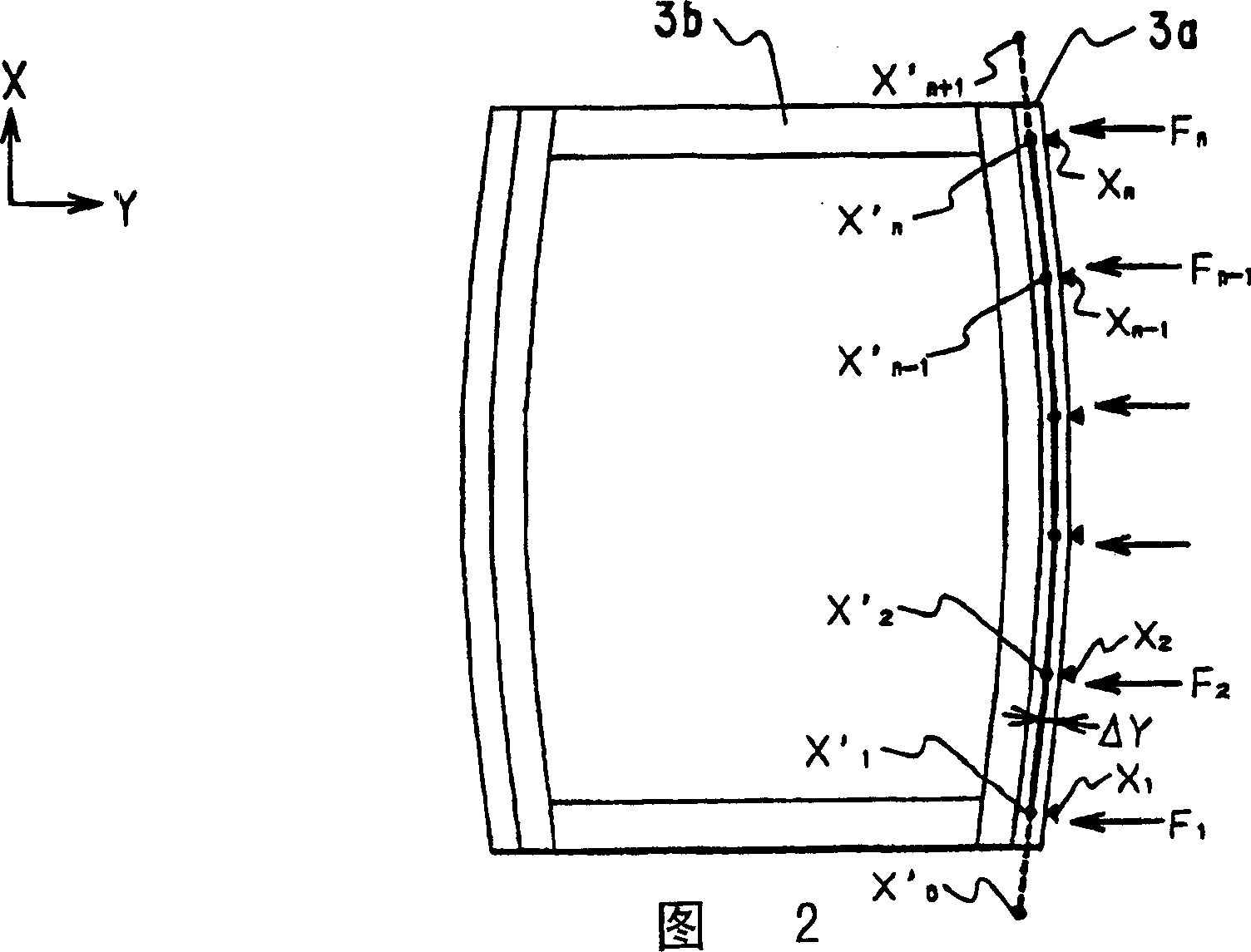

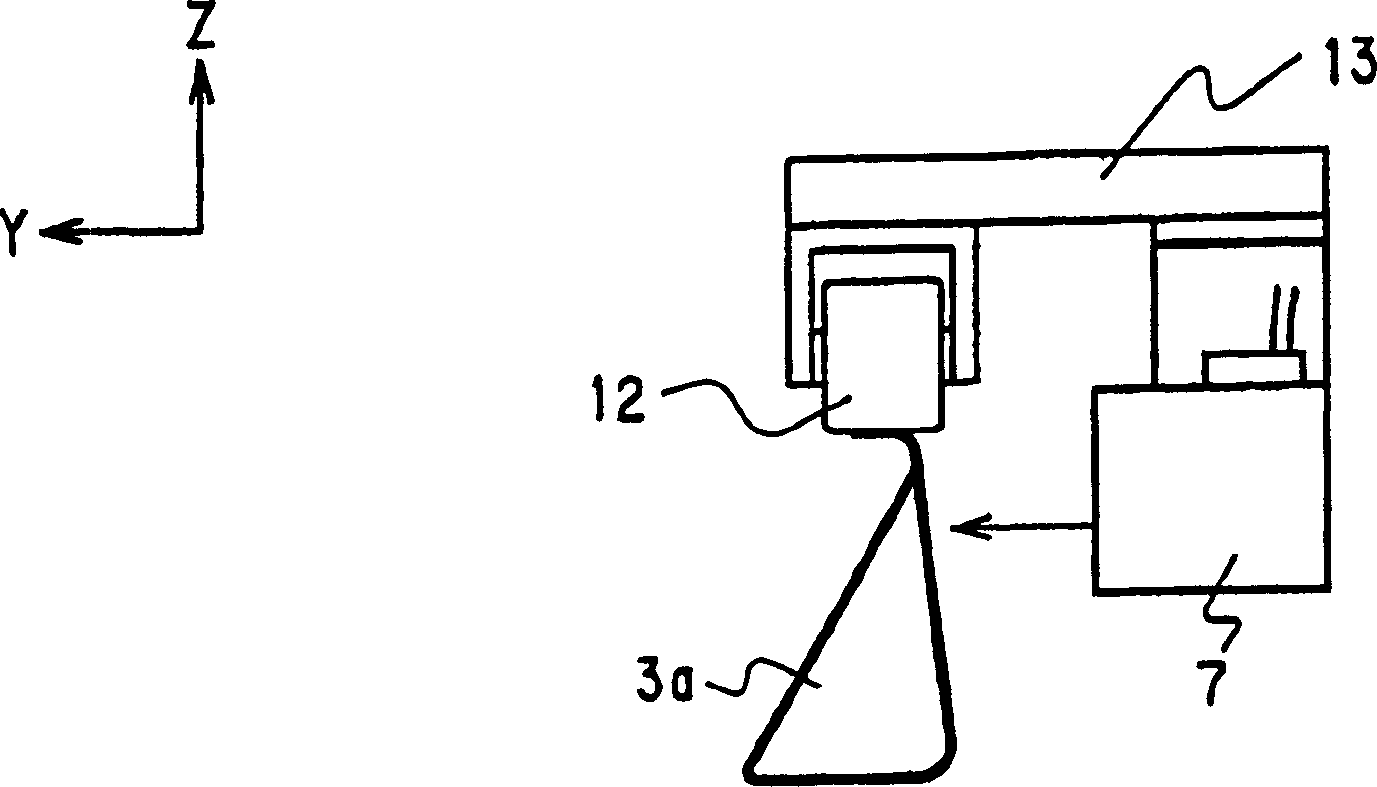

[0040] Below, refer to Figure 1 ~ Figure 3 Embodiments of the present invention will be described in detail. in addition, Figure 1 ~ Figure 3 , against the above Figure 4 ~ Figure 12 The same reference numerals are assigned to elements that are the same as or correspond to elements shown in .

[0041] figure 1 It is a perspective view showing the structure of a manufacturing apparatus for a color selection electrode according to an embodiment of the present invention. In this figure, 3a is a frame member, 3b is an elastic member connecting a pair of frame members 3a, 4 is a roller electrode, 6 is a roller electrode lifting mechanism, 7 is a measuring device for measuring the shape of the frame member 3a, and 8 is a control diagram. In the XYZ coordinate system of the roller electrode 4 in the rotation direction of the X-axis deviation of the rotation direction drive mechanism, 9 is the Y direction drive mechanism, 10 is the pillar, 11 is the elevating mechanism of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com