New type series-parallel connected three degrees of freedom mechanism in pure rotational motion

A technology with a degree of freedom and pure rotation, applied to the parts of the instrument, instruments, etc., can solve the problems that are difficult to meet the design technical index requirements and small cross-sectional area, and achieve the effect of compact structure, small cross-sectional area and high rigidity

Inactive Publication Date: 2004-03-10

SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When a mechanism is required to realize the linkage of rotation around three coordinate axes, the rolling degree of freedom can realize continuous rotation, and the rotation range of the other two rotational degrees of freedom is not required, and the mechanism is required to have high rigidity and small cross-sectional area Under the above conditions, it is difficult to meet the design technical index requirements by adopting the above two forms respectively

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

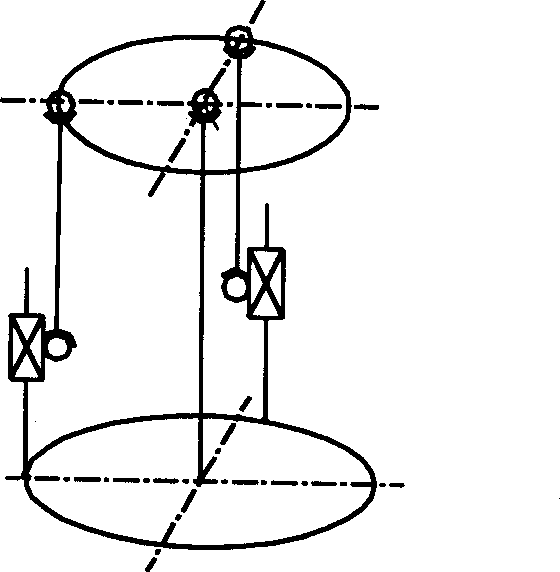

[0019] like image 3 Shown (slightly rotating joint 1) is a schematic diagram of the PSS type two-degree-of-freedom parallel mechanism of the present invention. The lengths of two connecting rods 2 with moving degrees of freedom are fixed, and one end thereof is slidably connected along a fixed guide rail slider.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

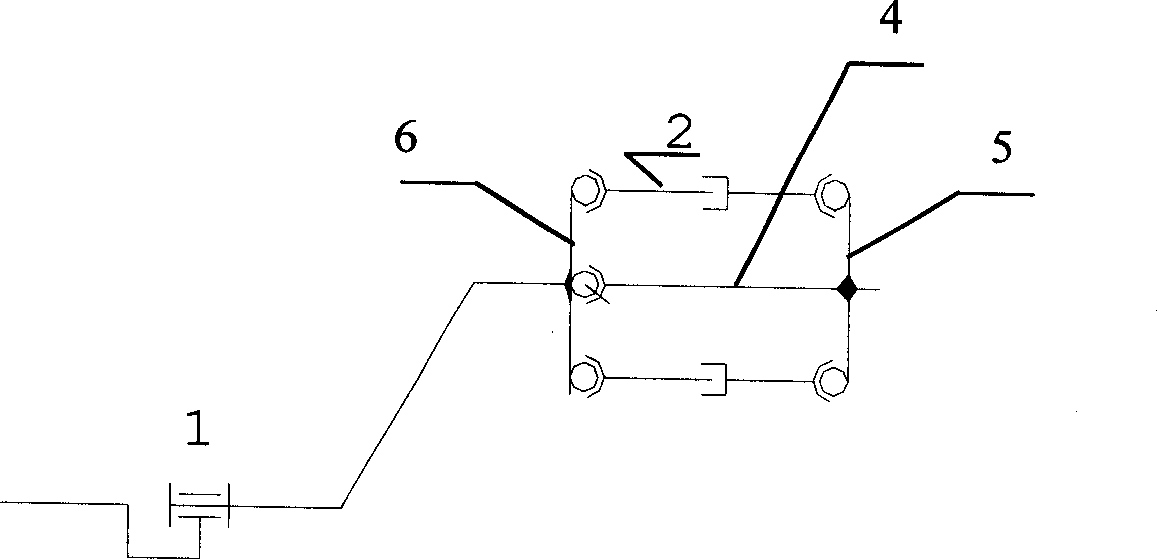

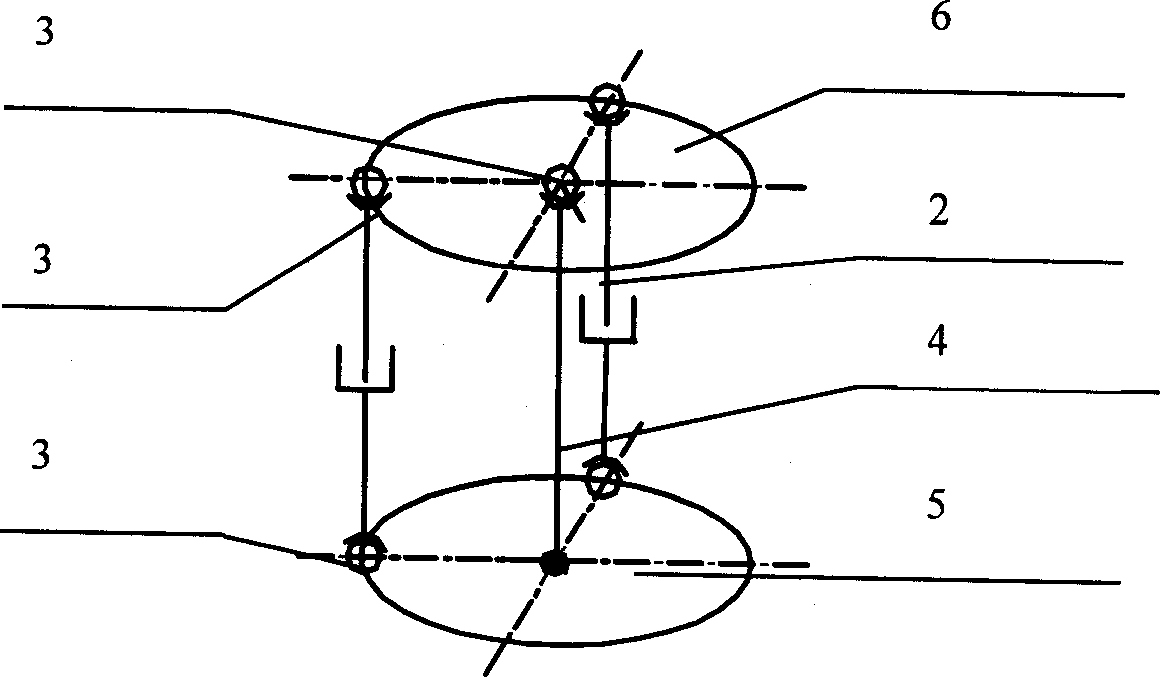

The mechanism consists of rotating joint, connecting bar possessing motion degree of freedom, central constraint pole, upper platform and lower platform. Revolving axis of the rotating joint is connected to the upper platform rigidly. One end of the central constraint pole is connected to the center of the lower platform rigidly, and the other end is connected to the upper platform through a ball pair. Two ends of two pieces of connecting bar possessing motion degree of freedom are connected to upper platform and lower platform through ball pairs, and distributed on a circle with a crossing point between the central constraint pole and platform being as circle center. The invention realizes interlocked rotations around three coordinate axes. Continuous turning can be realized in rolling degree of freedom, rotating range of other two-degree of rotational freedom is not large. The invented mechanism is utilized to application needed of high rigidity and small sectional area.

Description

technical field [0001] The invention relates to a three-degree-of-freedom pure-rotation mechanism, in particular to a novel series-parallel pure-rotation three-degree-of-freedom mechanism. Background technique [0002] There are many existing three-degree-of-freedom pure rotation mechanisms, which are mainly divided into two types. One is a series structure, that is, the rotation around three coordinate axes respectively; the other is a parallel structure, that is, most of them are based on the STEWART platform structure. Parallel motion platform and other structural forms. The above two forms have their own advantages and disadvantages and application occasions. When a mechanism is required to realize the linkage of rotation around three coordinate axes, the rolling degree of freedom can realize continuous rotation, and the rotation range of the other two rotational degrees of freedom is not required, and the mechanism is required to have high rigidity and small cross-sect...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G12B5/00

Inventor 徐志刚房立金王洪光陈书宏

Owner SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com