Method for testing coupling property of magnetic suspension rotor system and tesl platform

A technology of magnetic levitation rotor and test method, which is applied in the direction of measuring device, magnetic variable measurement, instrument, etc., and can solve the problems that have not been seen in the report of the test bench for the coupling characteristics of the magnetic levitation rotor system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

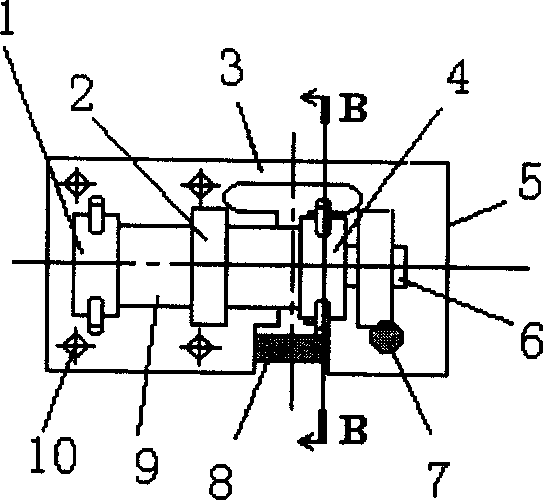

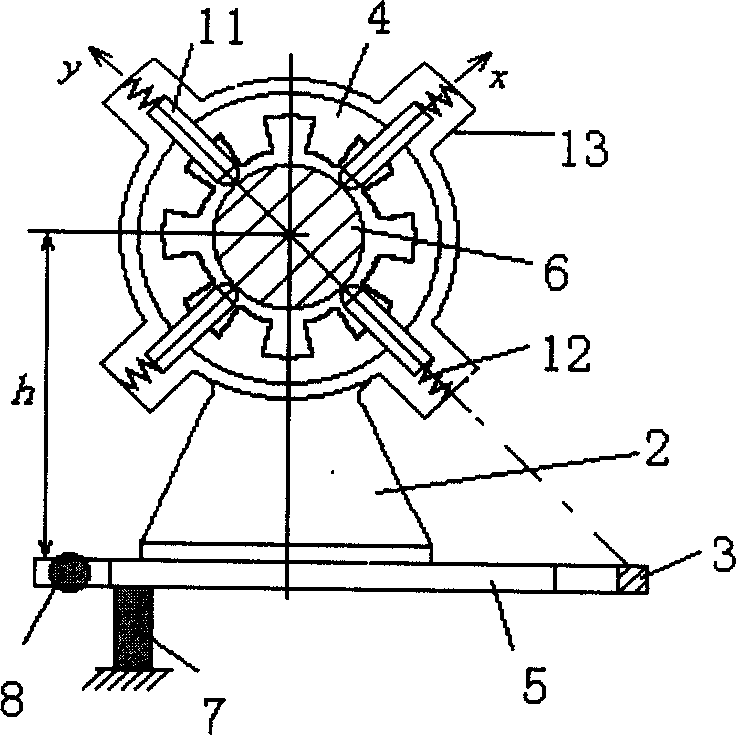

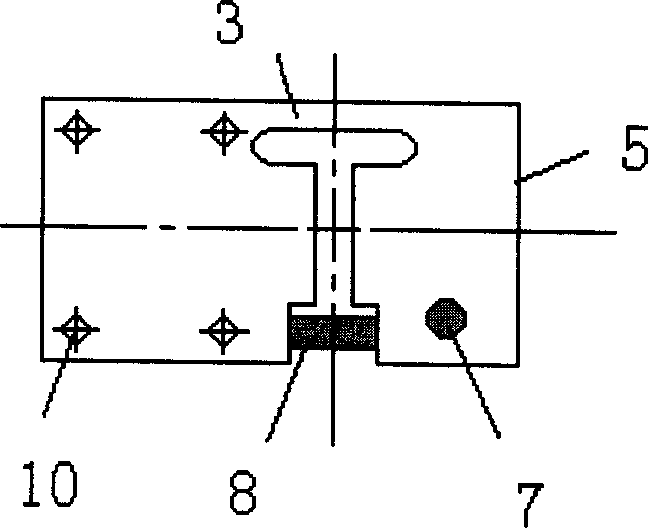

[0021] The present invention will be further described below in conjunction with example and accompanying drawing.

[0022] The inventors have found through research on the coupling of the magnetic levitation rotor system that: in the magnetic levitation rotor system, the coupling force of the radial magnetic bearing is caused by the eccentricity of the rotor, while the coupling torque is caused by the tilt of the rotor. Therefore, testing the coupling force and coupling torque to simulate the eccentricity and inclination of the maglev rotor is the key to the problem. Suspension force F yy Coupling force F at eccentricity at 90° and 270° yx = 0, that is, there is no coupling force on the y-axis; the suspension force F xx Coupling force F at eccentricity at 0° and 180° xy =0, that is, there is no coupling force on the x-axis. But there are coupling forces when the eccentricity is in other orientations. This phenomenon can be defined as: the non-superposition of the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com