Bulking recovering method of non-woven fabric

A recovery method, non-woven technology, applied in non-woven fabrics, textiles, papermaking, apparel, etc., can solve problems such as reduced bulkiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1~4

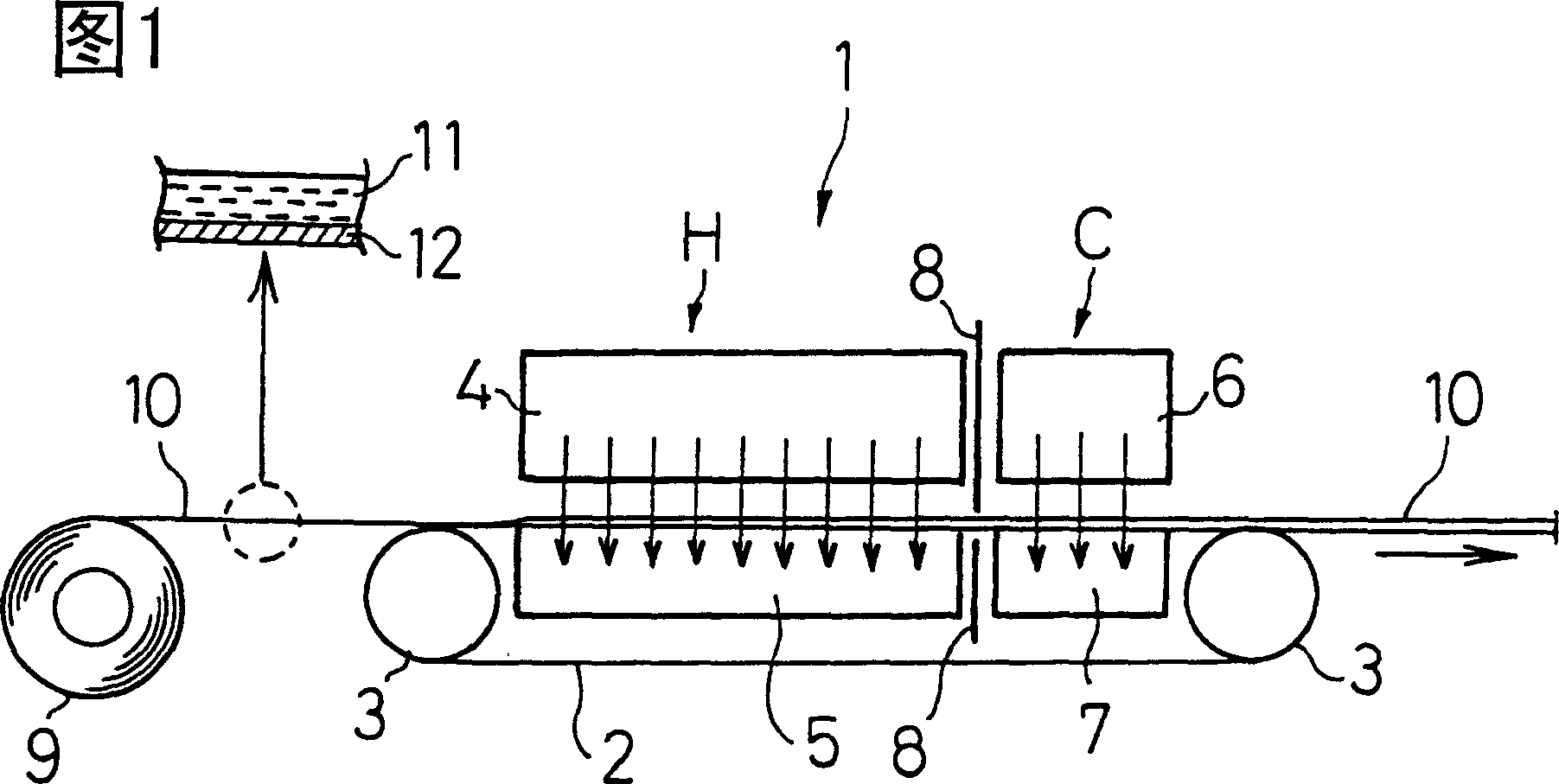

[0080] The nonwoven fabric A and the nonwoven fabric B wound into rolls were sent out at the speed shown in Table 1, and hot air was blown on the nonwoven fabric under the conditions shown in the same table. For Examples 1-5 and Comparative Examples 1-2 Figure 4 (without cooling zone C) plant implementation. Embodiments 6 and 7 blow hot air in a desktop constant temperature dryer, and the hot air passes through (air-ventilated) non-woven fabrics. In Comparative Examples 3 and 4, hot air was blown with a hair dryer, but the hot air was not passed through. Examples 1-7 and Comparative Examples 1-4 performed natural cooling after blowing hot air. The thickness of the nonwoven fabric before and after blowing was measured by the following method. The results are shown in Table 1 below. Then, the raw fabric rolls of the nonwoven fabric A and the nonwoven fabric B wound into rolls were stored at room temperature (about 23° C.) for 2 months or more. The basis weight of the non-wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com