Separation filler for mfg. LCD display panel and method of controlling distance of nozzle and substrate

A liquid crystal display panel and dispenser technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of reduced productivity, reduced reliability, inconvenient operation of equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Reference will now be made in detail to specific embodiments of the invention, examples of which are illustrated in the accompanying drawings. In the drawings, the same reference numerals refer to the same or similar parts.

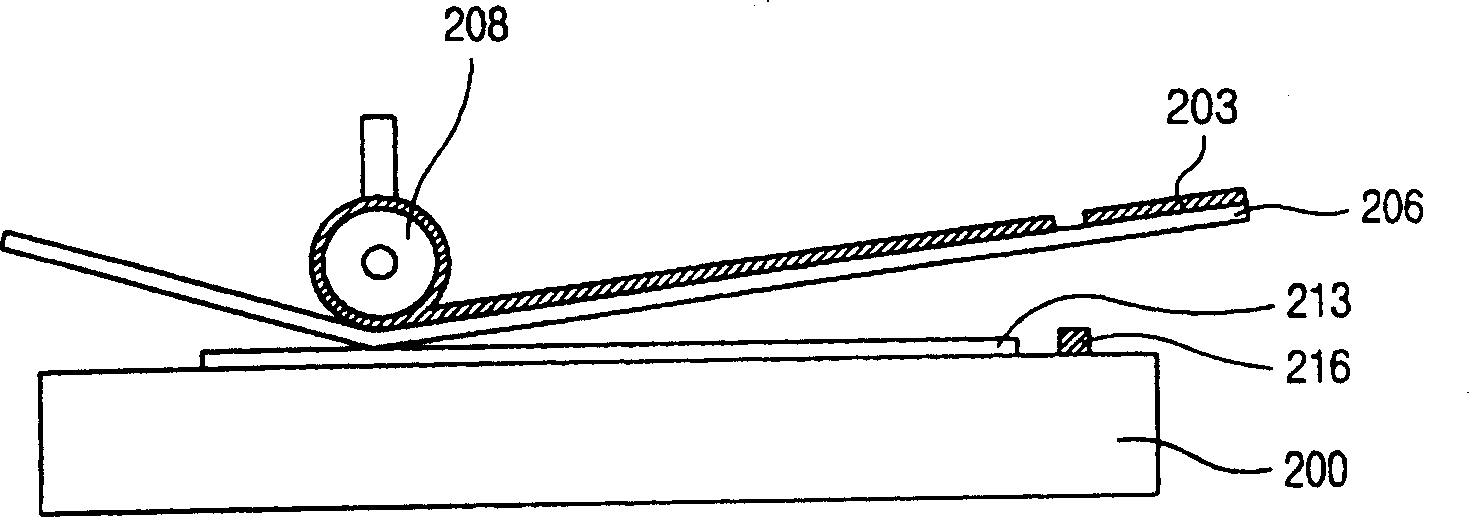

[0060] Figure 6 Shown is a dispenser for manufacturing liquid crystal display panels according to the present invention.

[0061] exist Figure 6 Among them, the dispenser according to the present invention includes: a syringe 503 with a nozzle 502 at one end for providing sealant to a substrate 501 on a workbench 500; a bed 504 on which the syringe 503 is mounted; a contact switch 509 according to Whether the nozzle 502 of the syringe 503 is in contact with the substrate 501 and realize switch switching; the first sensor 507 detects the initial value when the nozzle 502 of the syringe 503 and the substrate 501 are in contact with each other according to the contact switch 509; the vertical drive motor 505 is used for The bed 504 is driven vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com