Customized production monitoring and warning system and method thereof

A user and production line technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as difficulty in mastering, ineffective monitoring and management of customized production lines, and many production lines changing factors by row.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

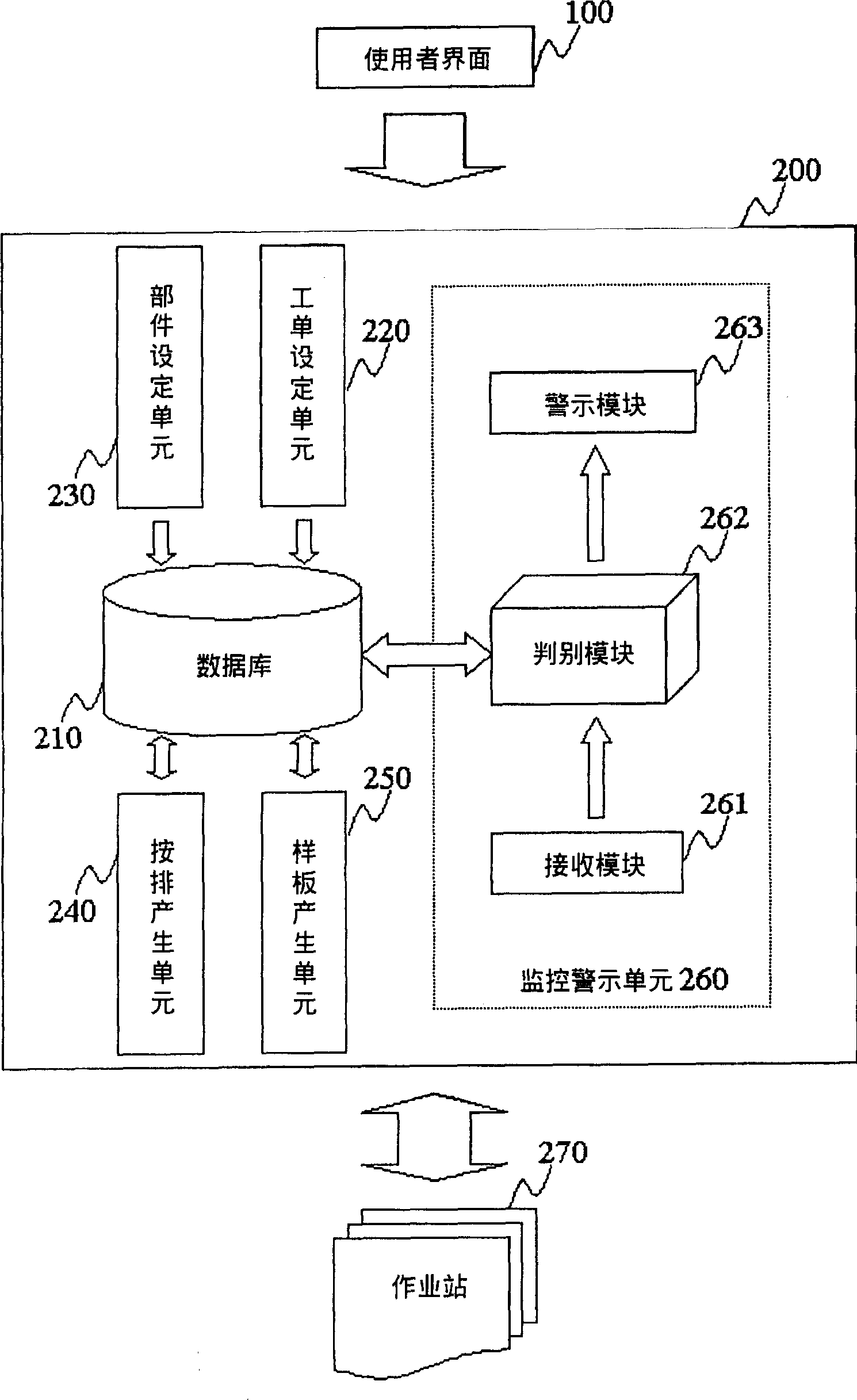

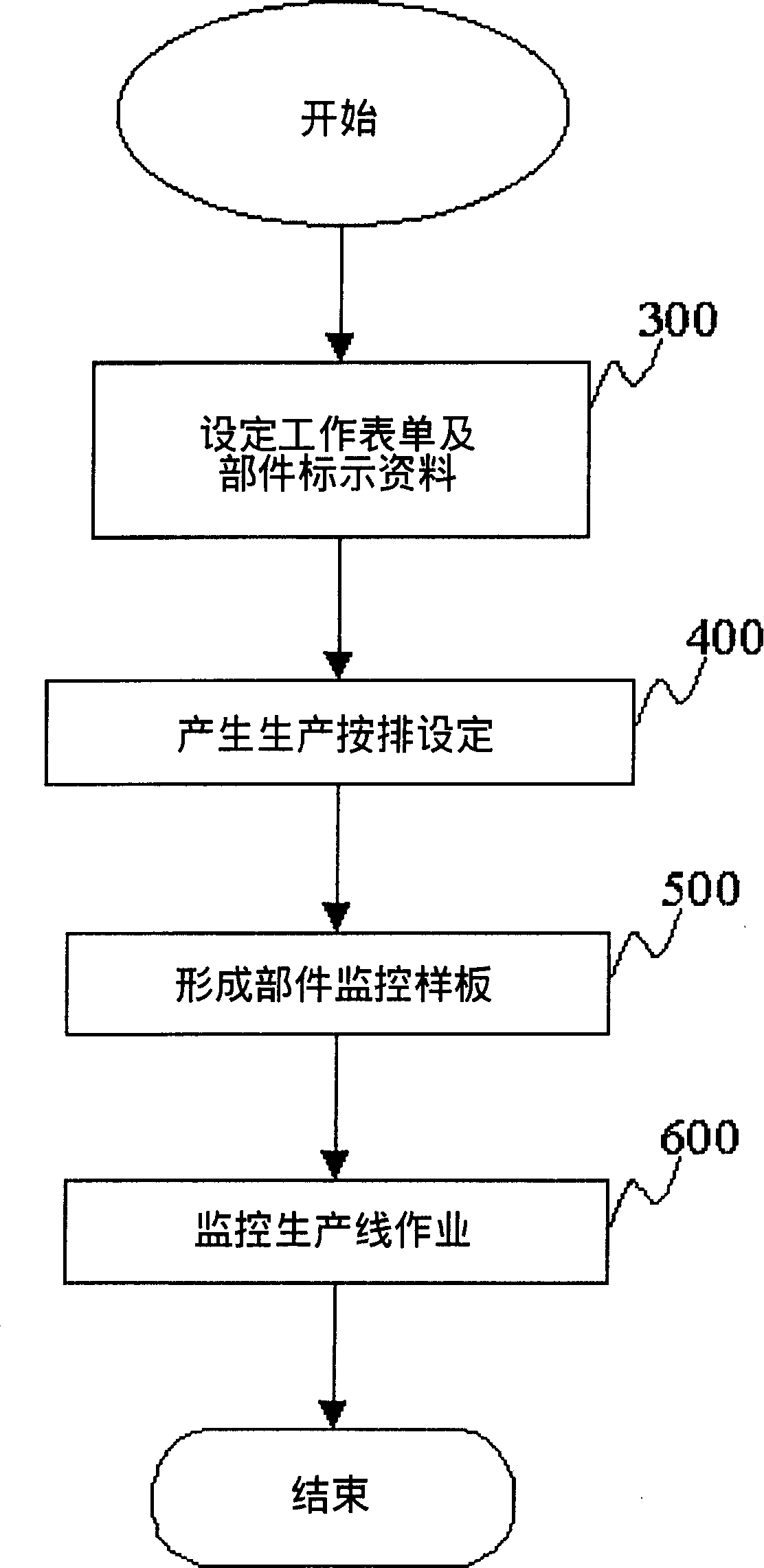

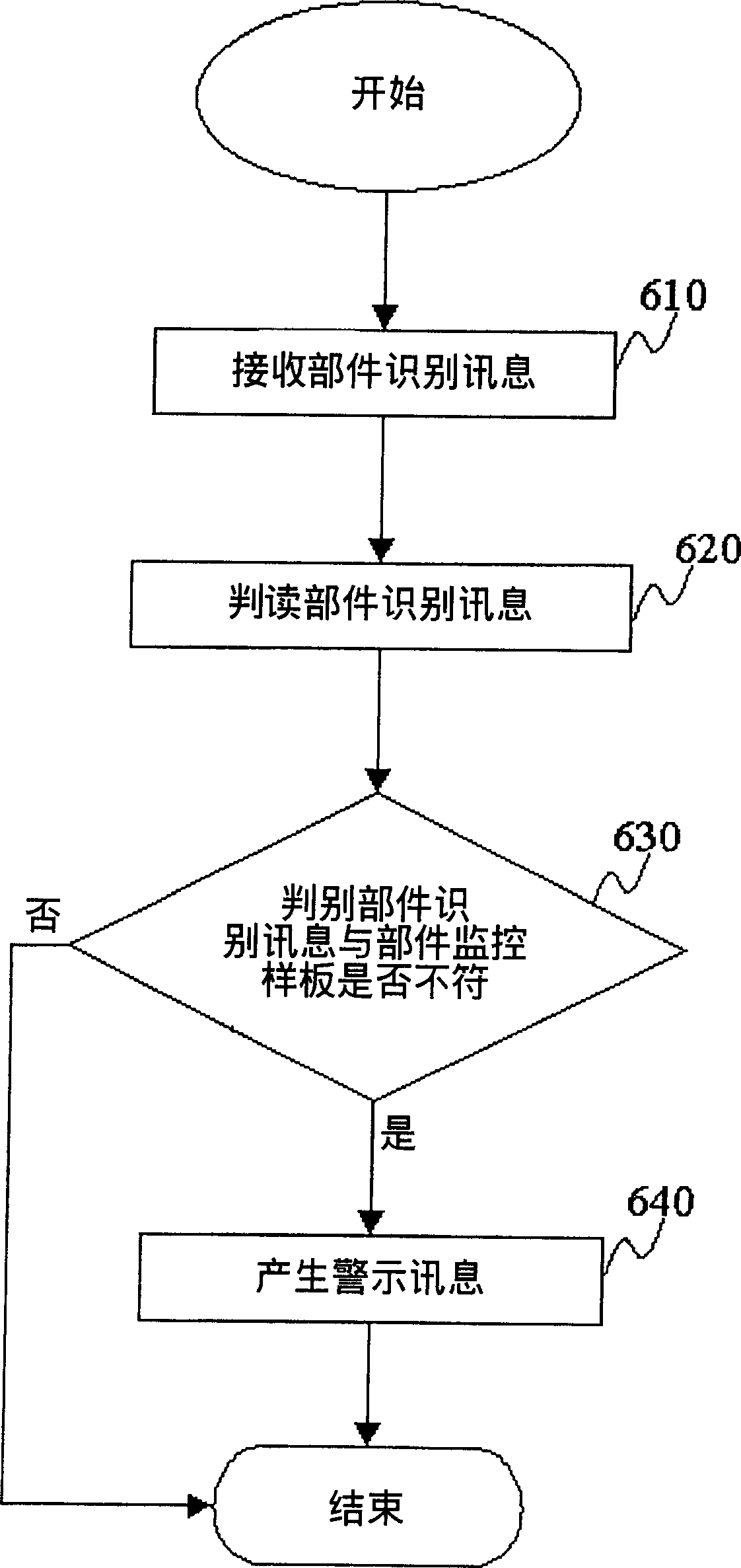

[0016] refer to figure 1 , the present invention is a customized production monitoring and warning system and method thereof, mainly combining an order data with component codes, and inputting them into the customized production monitoring and warning system 200 through the user interface 100, so that the generated "production according to schedule "Settings" can be extracted from a "parts monitoring template" to monitor and manage customized production operations. From figure 1 It can be seen from the figure that the system structure of the customized production monitoring and warning system 200 includes a database 210, a work order setting unit 220, a component setting unit 230, an arrangement generation unit 240, a template generation unit 250 and a monitoring and warning unit 260, wherein:

[0017] (1) The database 210 stores "production line information". In this embodiment, the "production line data" at least includes the standard operation content, operation process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com