Method for picking semiconductor chips from a foil

A semiconductor and chip technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problem of not knowing at what height the chip clamp stops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

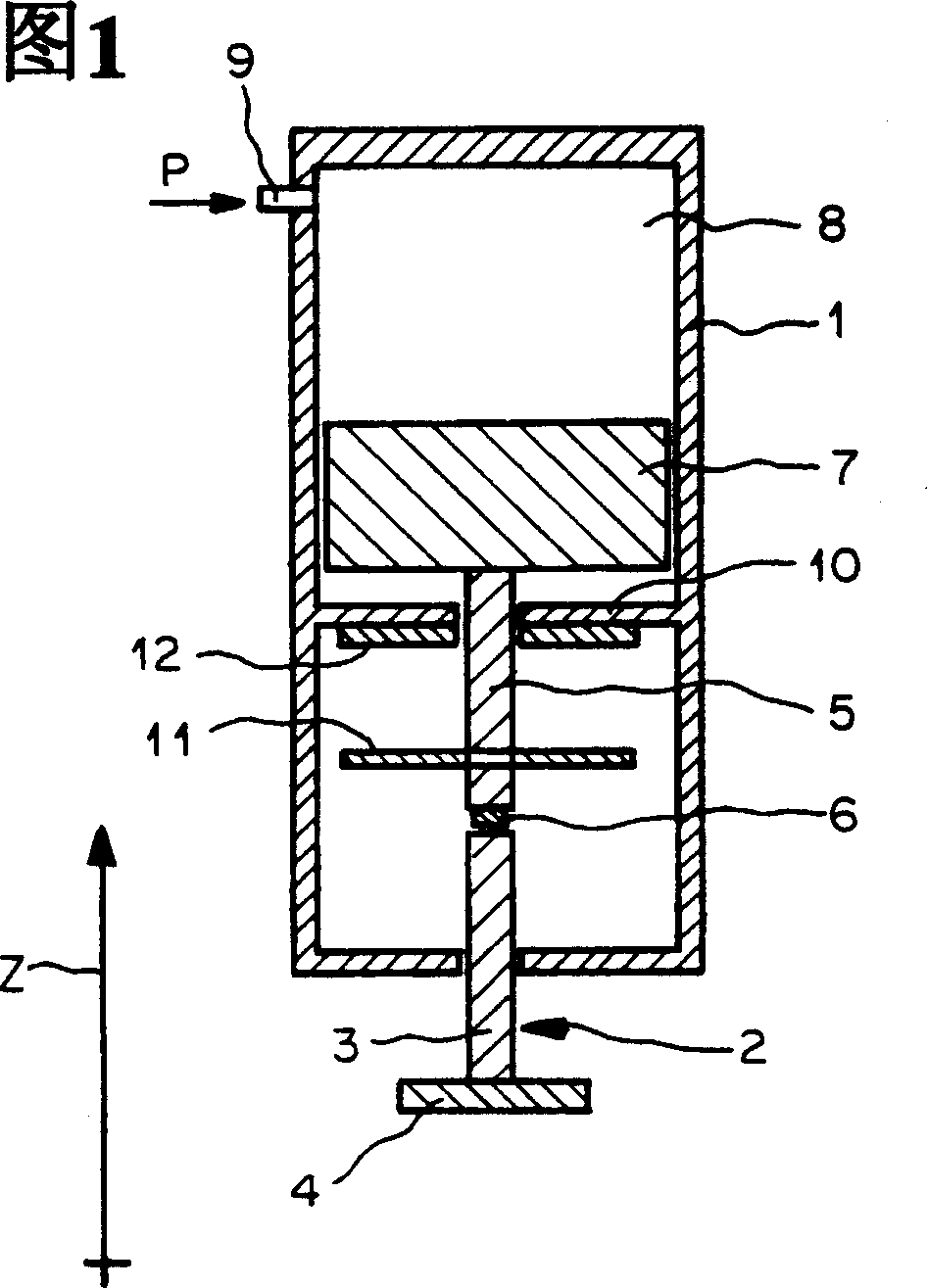

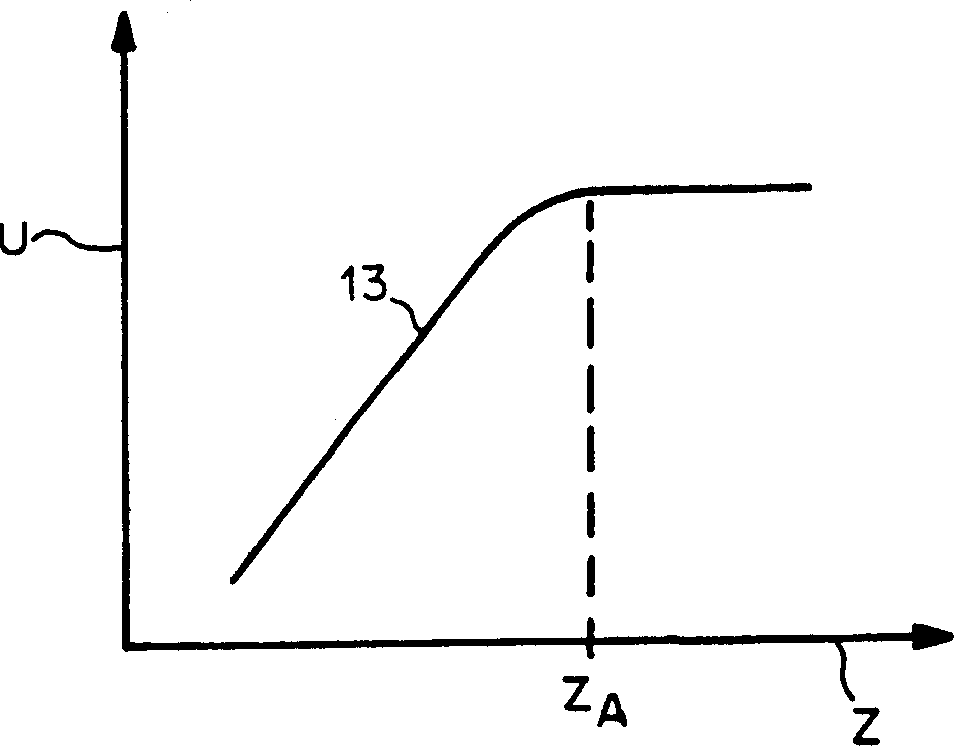

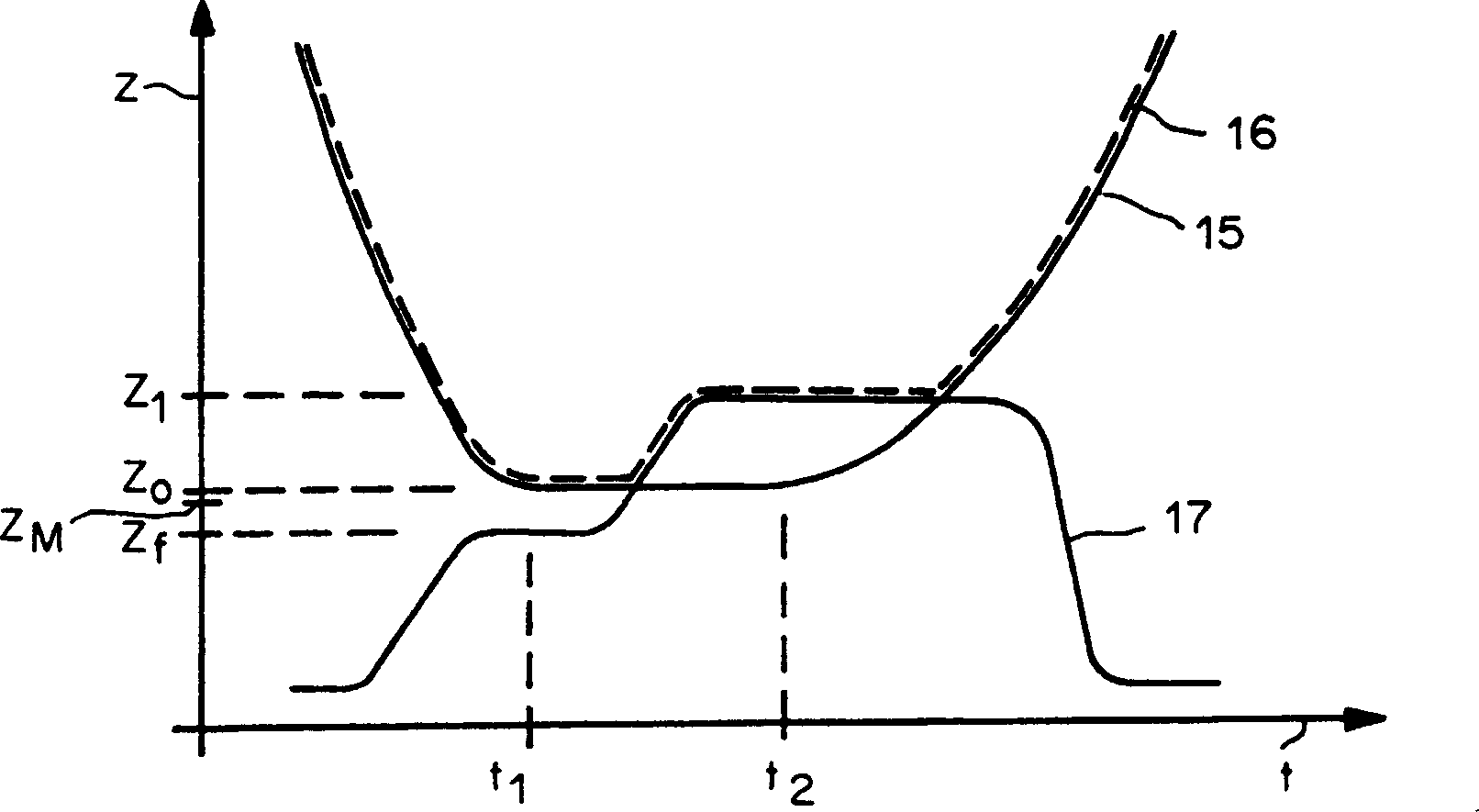

[0024] FIG. 1 shows a first exemplary embodiment of a bonding head 1 of a die bonder, whereby only the elements of the bonding head 1 that are necessary to facilitate the understanding of the invention are shown and described. The bonding head 1 belongs to a pick-and-place system, which serves to pick up semiconductor chips presented on a wafer table and to place them on a substrate. With this embodiment, the bonding head 1 is lowered in a direction designated as the Z direction to pick up the semiconductor chip, then raised again, transferred to the substrate, and lowered again to place the semiconductor chip on the substrate. In order to accurately move the bonded head 1 in the Z direction, the Z position of the bonded head 1 must be measured with an unused driver and an unused measuring system. The drive can lower and raise the bonding head 1 in the Z direction relative to the pick-and-place system or can lower and raise the pick-and-place system and the bonding head 1 toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com