Rotating, soaking and pulling process of preparing photocatalyst film on circular tube as substrate

A photocatalyst, rotary impregnation technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of uneven coating of round tube substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

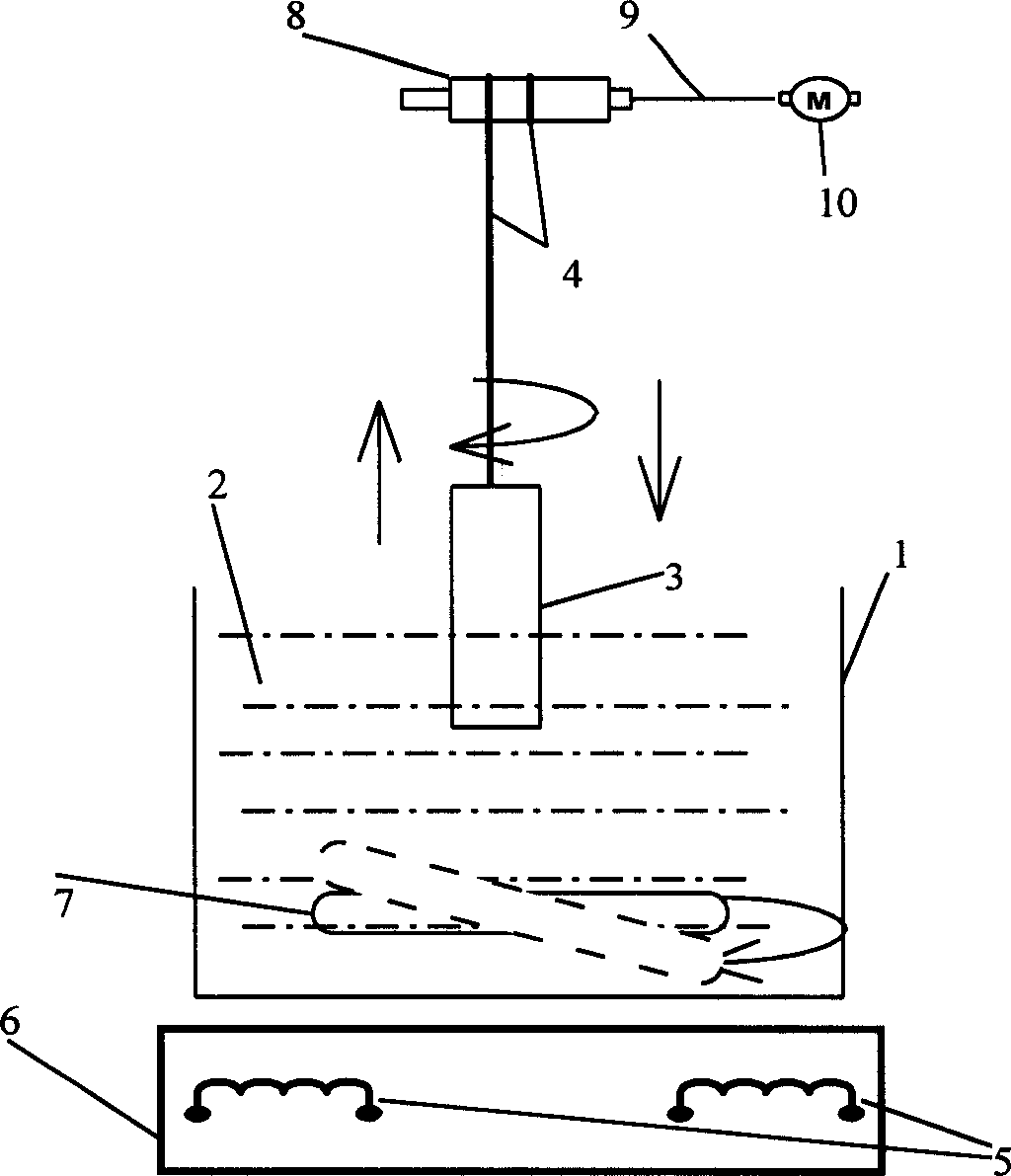

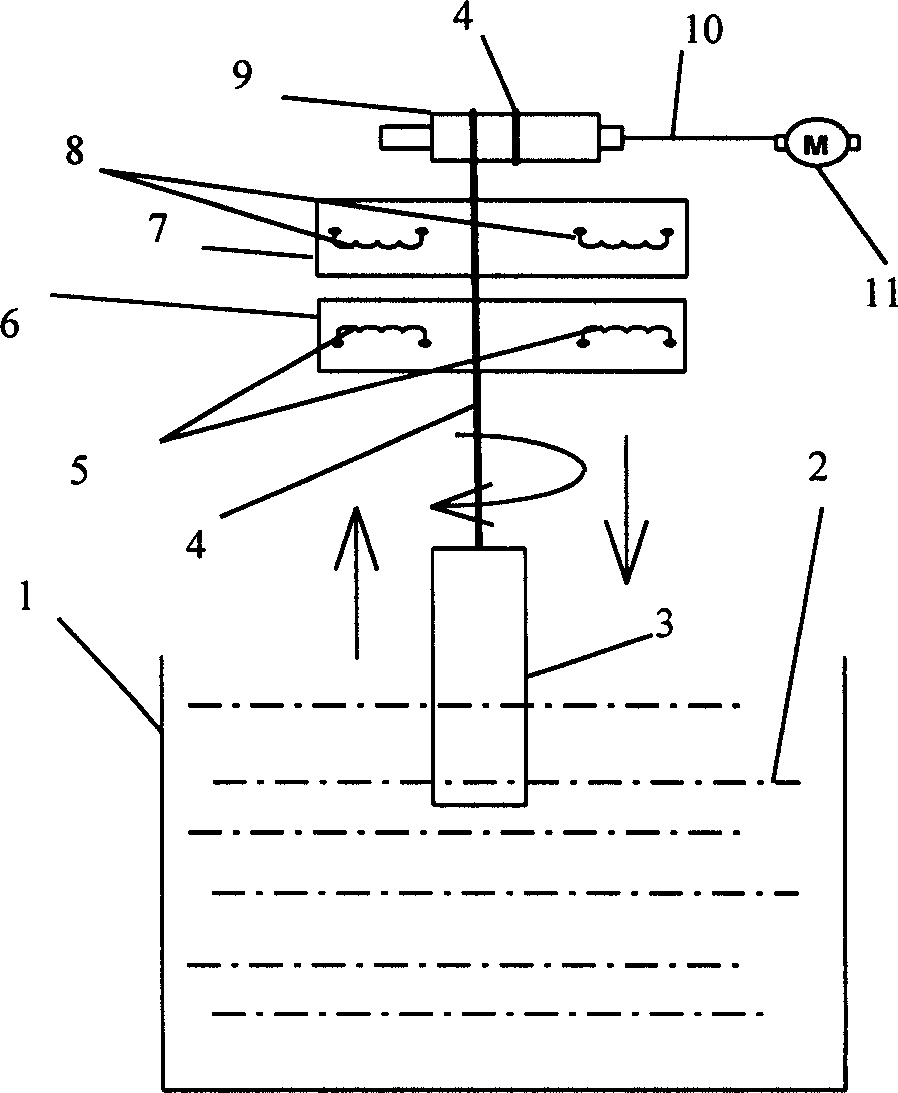

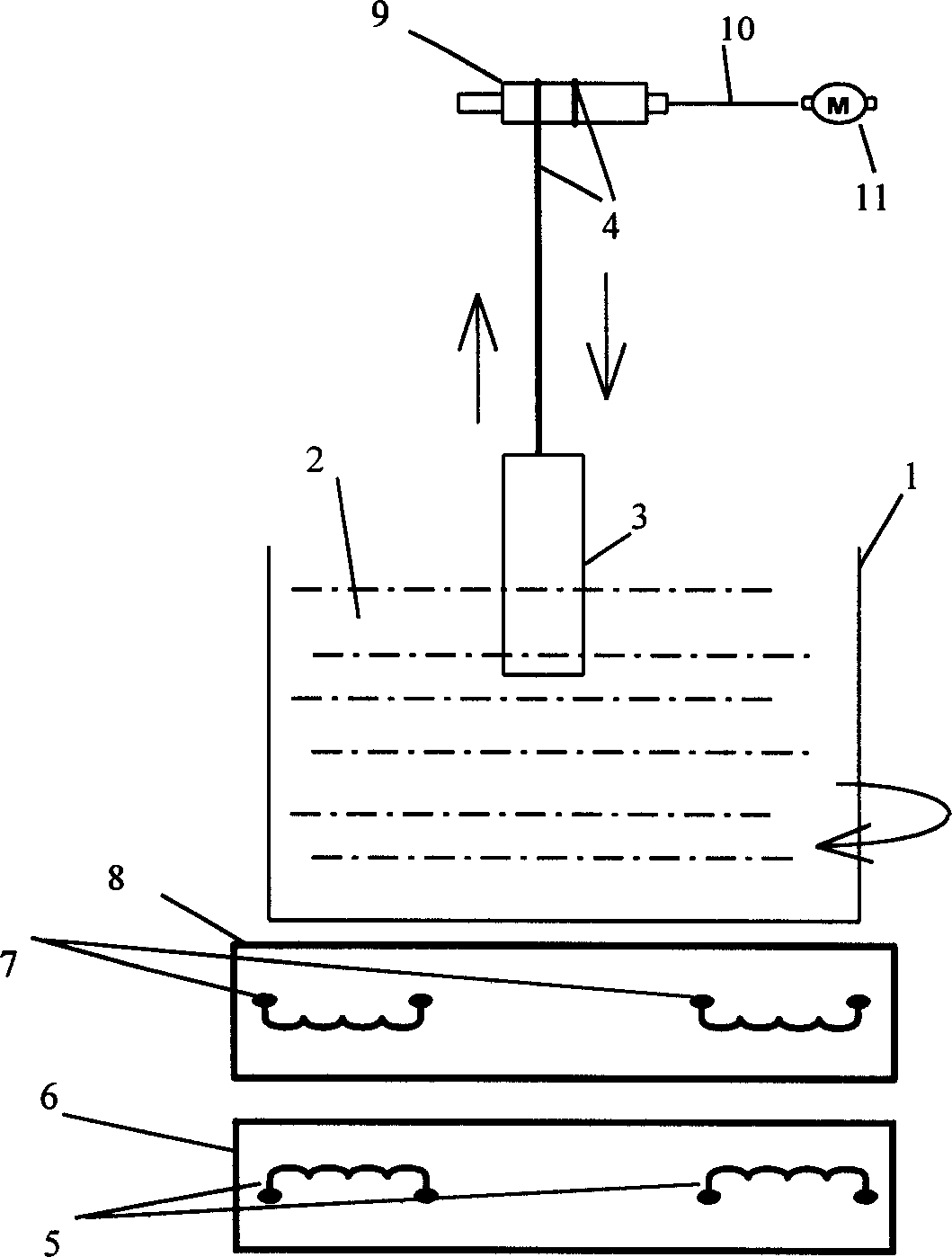

Method used

Image

Examples

Embodiment 1

[0022] Preparation of titanium dioxide solution: firstly mix n-tetrabutyl titanate, diethanolamine, water and absolute ethanol, and stir for 1 hour to obtain solution (1). Distilled water was mixed with the remaining ethanol to obtain solution (2). Then slowly add the solution (2) which has been transferred into the separatory funnel dropwise into the solution (1) under vigorous stirring, and continue stirring for half an hour to obtain a titanium dioxide solution. Among them, Ti(OC 4 h 9 ) 4 :EtOH:H 2 O:NH(C 2 h 5 Oh) 2 =1:26.5:1:1 (molar ratio), the concentration of titanium dioxide in this solution is 0.5 mol / liter.

[0023] The pretreatment process of ordinary glass round tubes (200mm×40mm (outer diameter)×2mm): Soak ordinary glass pieces (200mm×34mm×2mm) in concentrated nitric acid solution for two days, take them out, wash them, and then soak them in lotion After about two hours, wash it with distilled water, and then dry it in an oven to complete the pretreatme...

Embodiment 2

[0027] The concentration of titanium dioxide is 1.5 mol / L (Ti(OC 4 h 9 ) 4 :EtOH:H 2 O:NH(C 2 h 5 Oh) 2 =3:26.5:1:1 (molar ratio)), the pulling speed is 3mm s -1 , with a rotation speed of 200 rpm -1 , the rest of the method is the same as in Example 1, a titanium dioxide photocatalyst film is prepared on an ordinary glass tube, and the prepared titanium dioxide photocatalyst film is bright and uniform in film formation and has good photocatalytic performance.

Embodiment 3

[0029] The concentration of titanium dioxide is 0.3 mol / L (Ti(OC 4 h 9 ) 4 :EtOH:H 2 O:NH(C 2 h 5 Oh) 2 =0.6:26.5:1:1 (molar ratio)), the pulling speed is 3mm s -1 , with a rotation speed of 400 rpm -1 , after the wet film was dried in an oven at 100°C for 18min, the above operation was repeated 5 times, and then baked at 550°C for 1 hour. The obtained titanium dioxide photocatalyst thin film is bright and uniform in film formation and has good photocatalytic performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com