Track support for building machinery

A technology for construction machinery and track frames, applied in the field of track frames, can solve the problems of increased cleaning costs, a large amount of cleaning water, and many cleaning hours, and achieve the effects of reducing weight, reducing processing hours, and reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

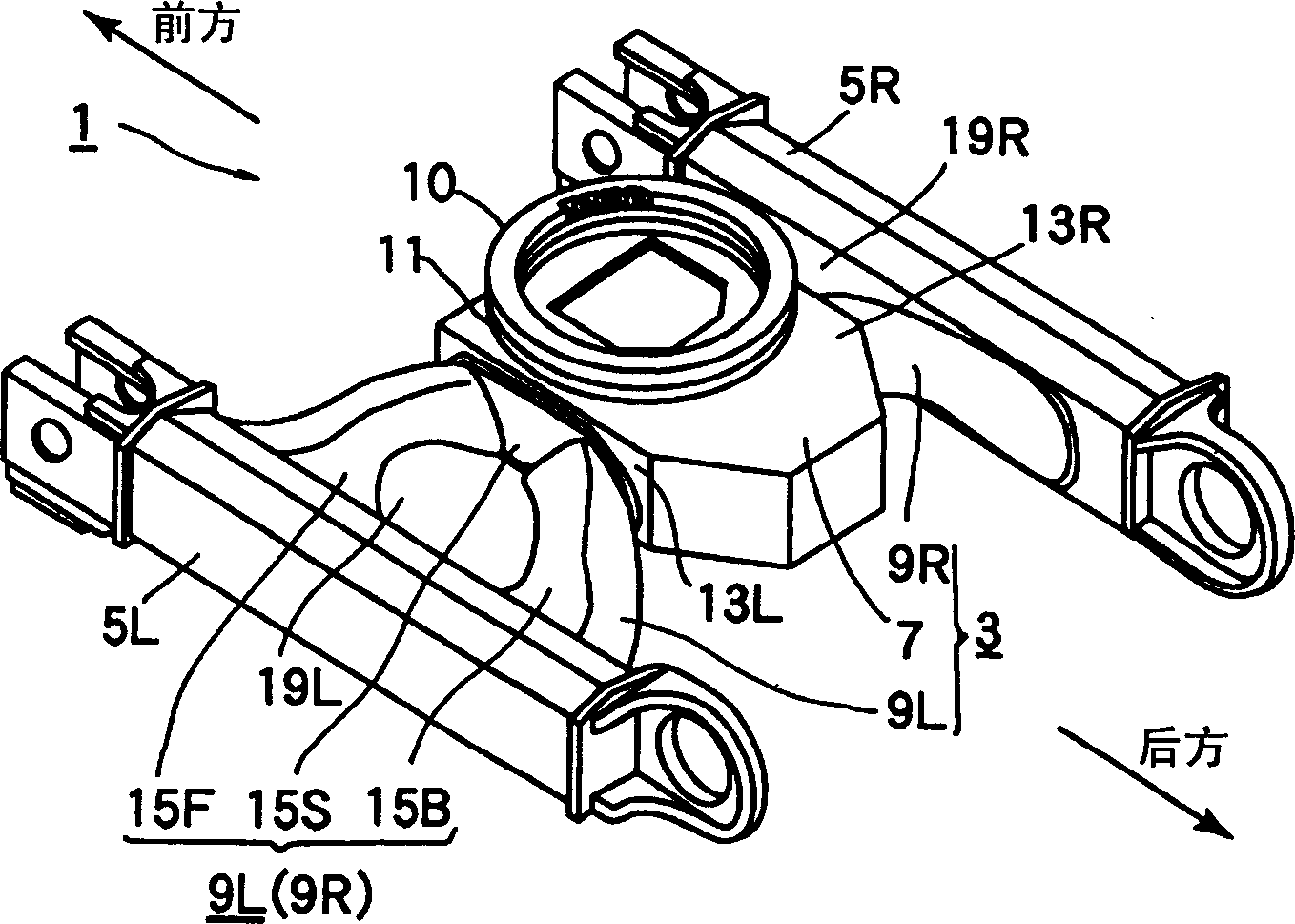

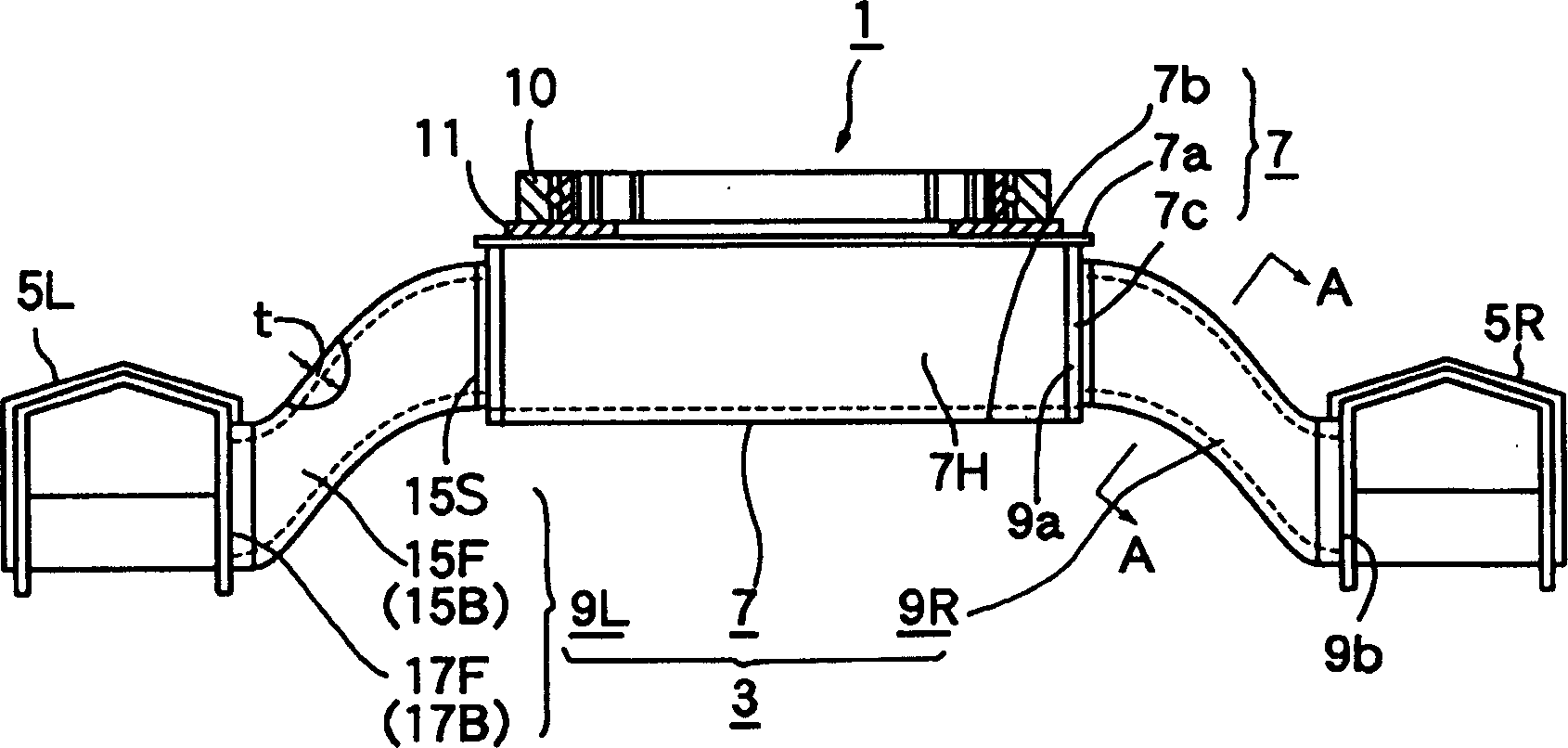

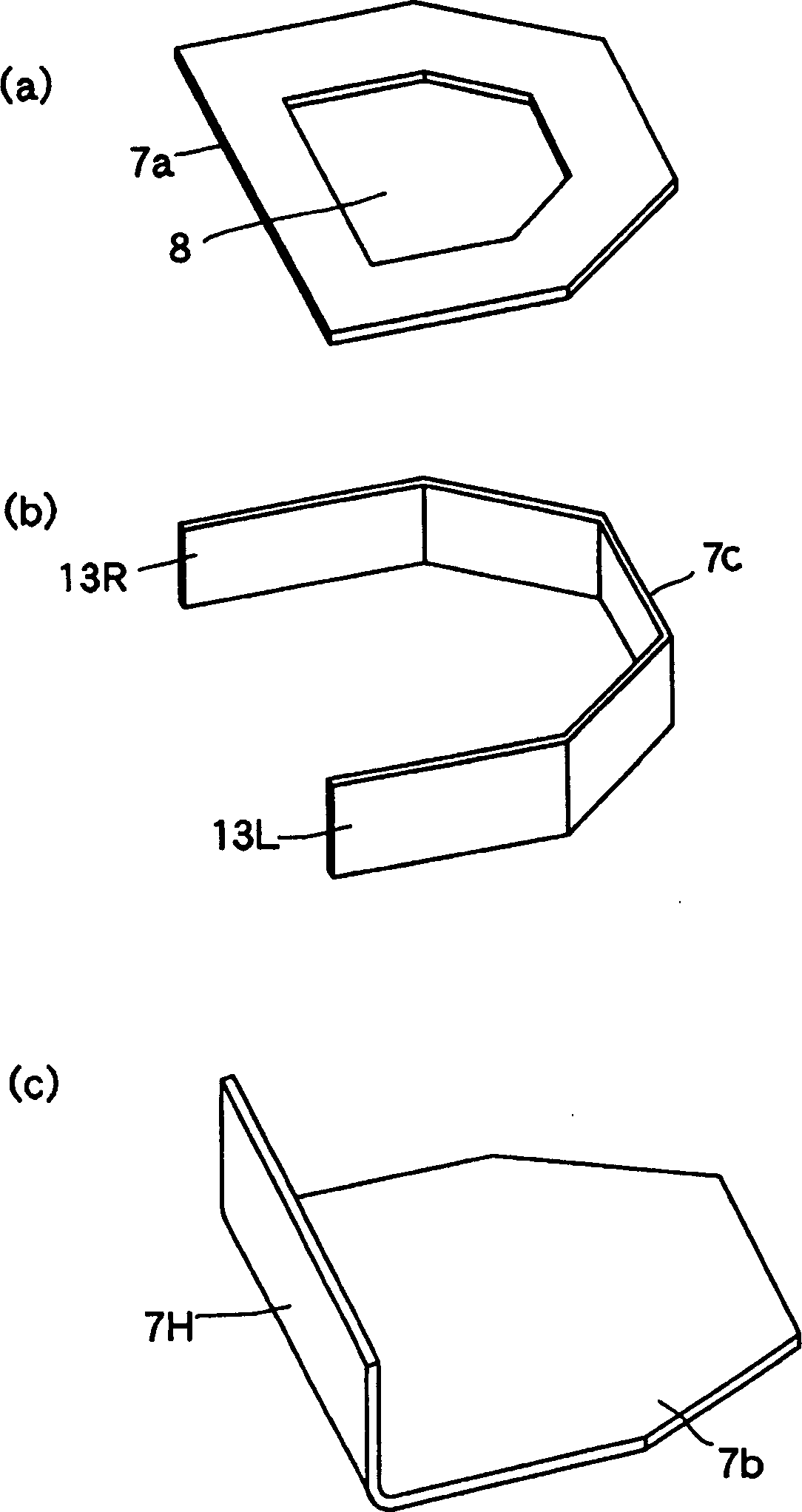

[0045] The specific embodiments of the crawler frame of the construction machine of the present invention will be described below with reference to the drawings.

[0046] First, use Figure 1 ~ Figure 5 The crawler frame of the construction machine according to the first embodiment of the present invention will be described.

[0047] figure 1 It is a perspective view of the appearance of a crawler frame of a construction machine according to the first embodiment of the present invention, figure 2 It is a front view of the crawler frame of the construction machine according to the first embodiment of the present invention, image 3 (a), (b), and (c) are developed views of the center frame portion of the center frame of the crawler frame of the construction machine according to the first embodiment of the present invention, Figure 4 It is an appearance side view of the legs of the center frame of the crawler frame of the construction machine of the first embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com