Beam connecting structure in house

A technique of building and structure, which is applied in the field of beam connection structure, can solve problems that require a lot of time, troublesome correction work, trouble, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

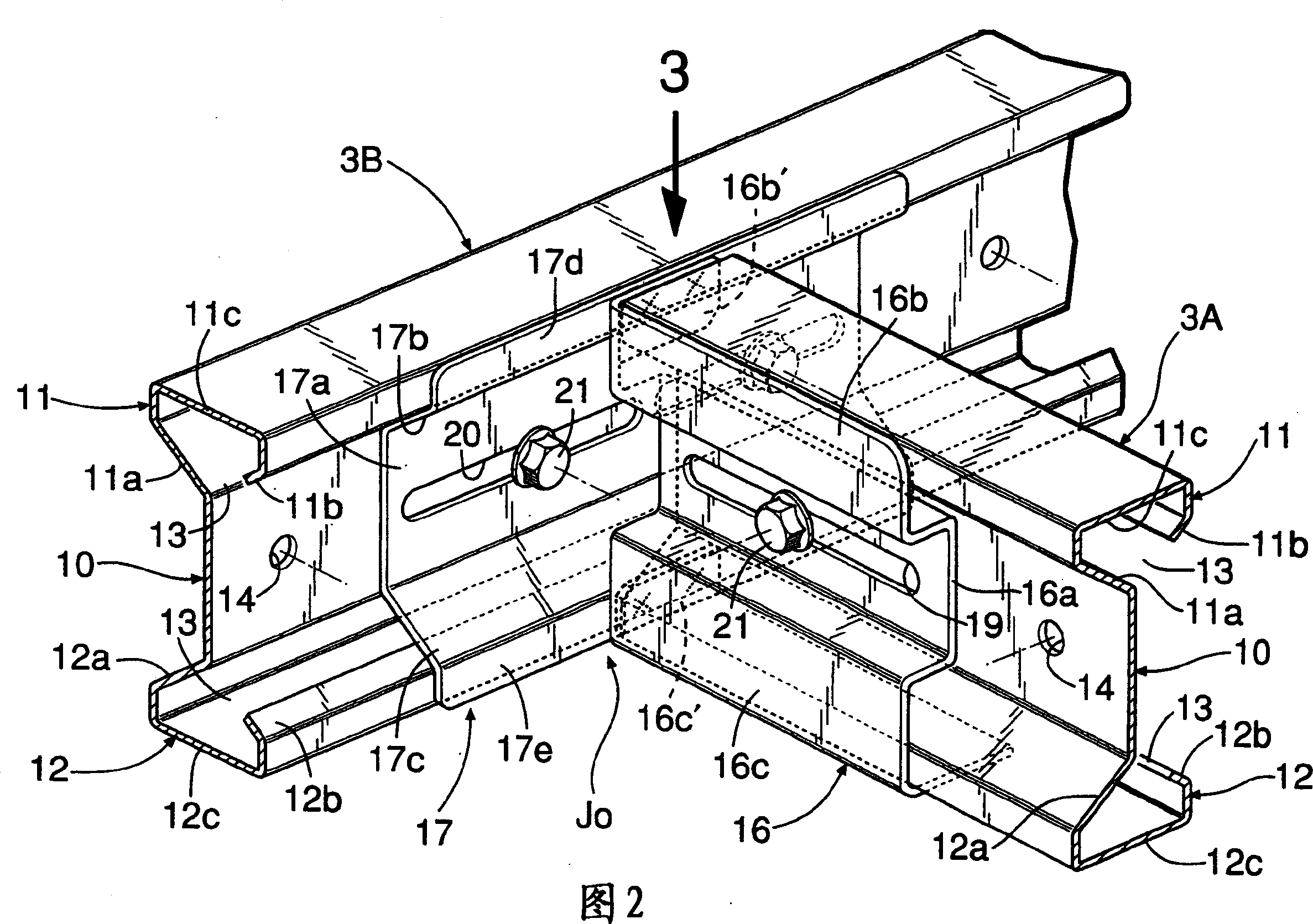

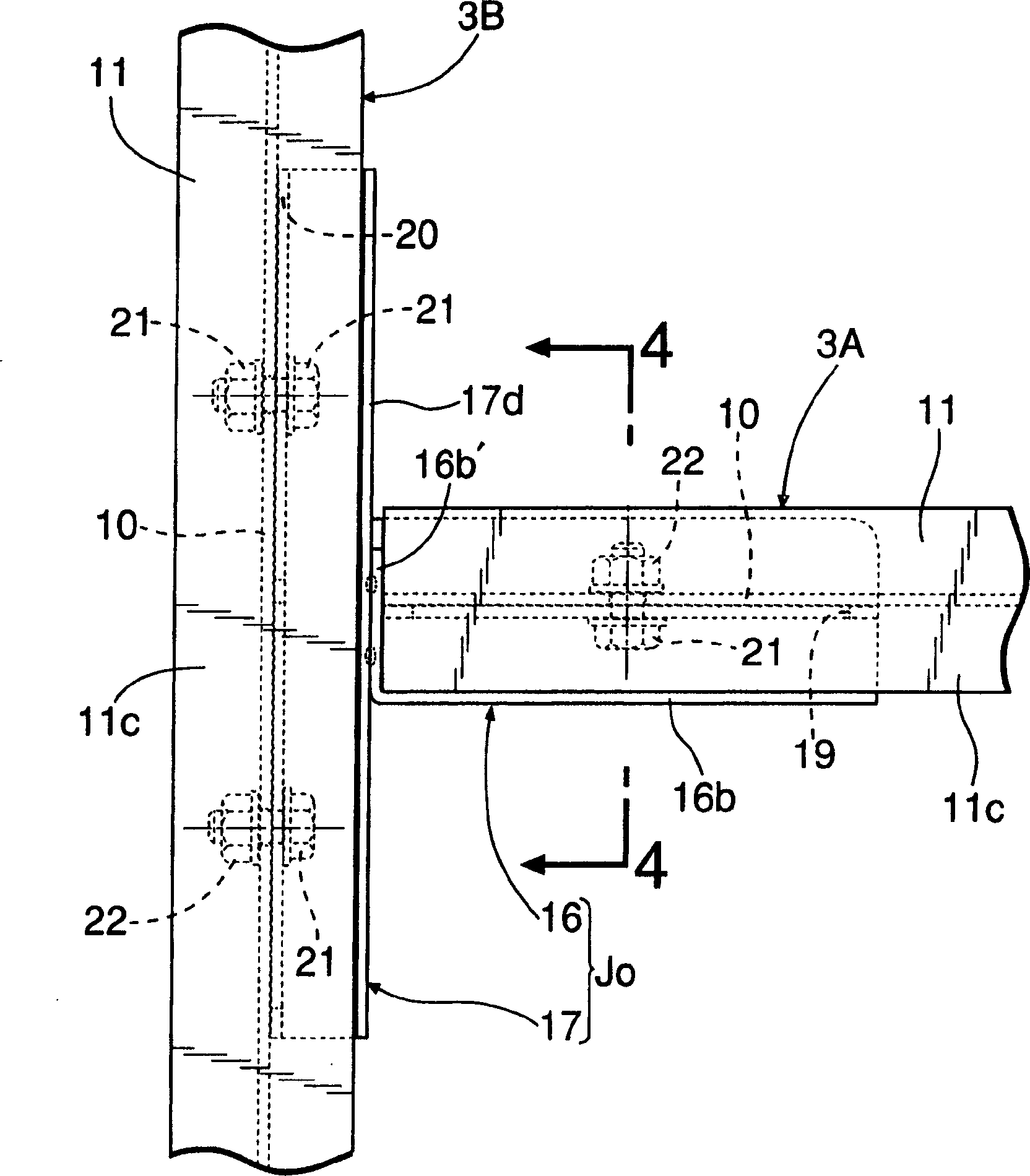

[0016] The implementation of the present invention will be described below according to the embodiments of the present invention shown in the accompanying drawings.

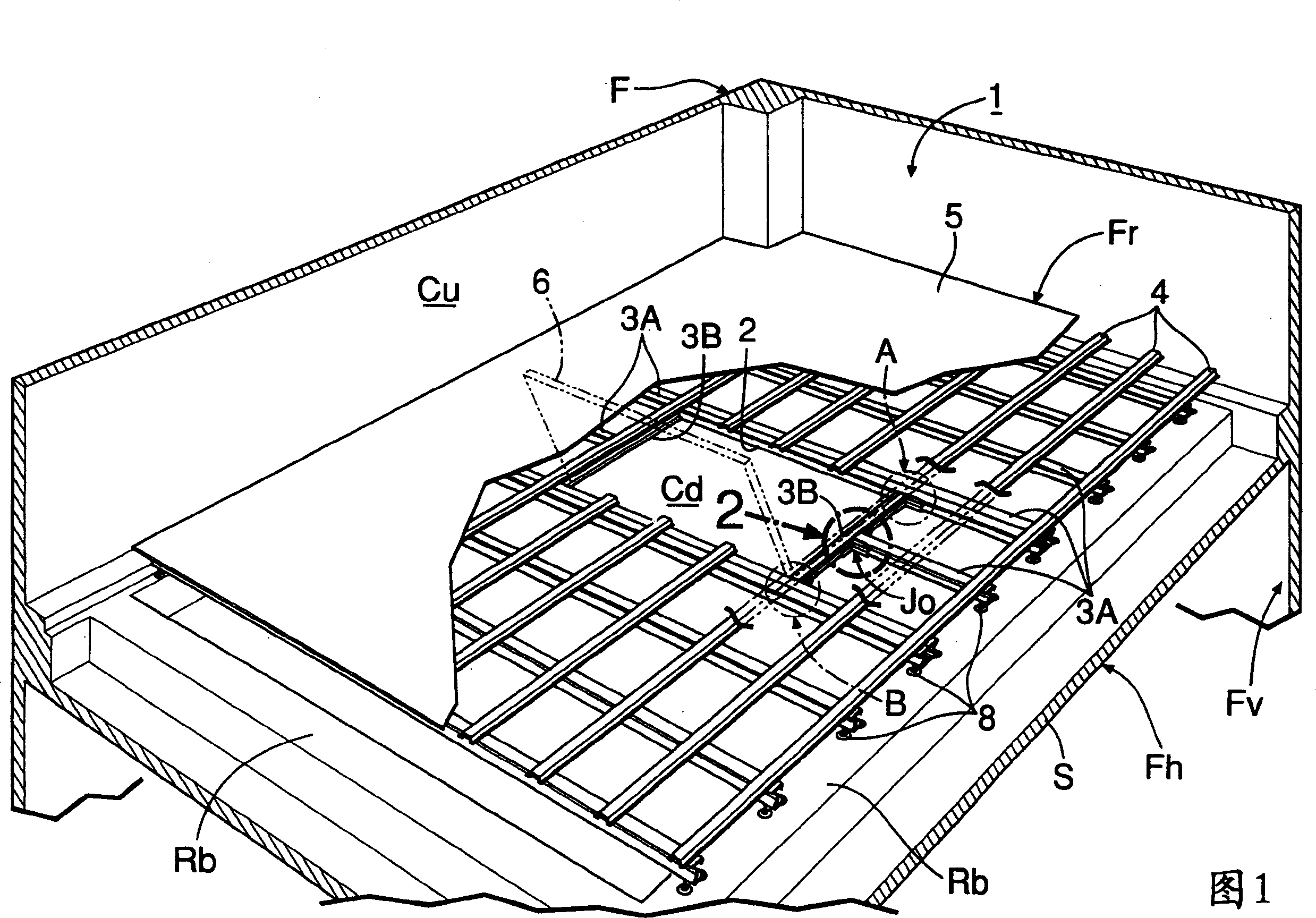

[0017] First, with reference to Figs. 1 to 5, an embodiment in which the beam connection structure of the present invention is implemented on the floor of a multi-story house having a concrete body with an inverted beam structure will be described.

[0018] In Fig. 1, the concrete body F constituting the skeleton of a multi-story house or the like has a horizontal body part Fh extending horizontally and dividing the house into upper and lower levels, and a horizontal body part Fh extending vertically and dividing the adjacent horizontal body part. The vertical body part Fv and the horizontal body part Fh which are connected to each other between the parts Fh are integrally provided with a plurality of reverse beams Rb protruding upward from the upper surface of the plate S to form a so-called reverse beam structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com