Non-inserted core optical fiber equipment used for optical back plate connecting system

A technology for optical backplanes and connecting devices, applied in the field of optical interfaces, can solve problems such as increasing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

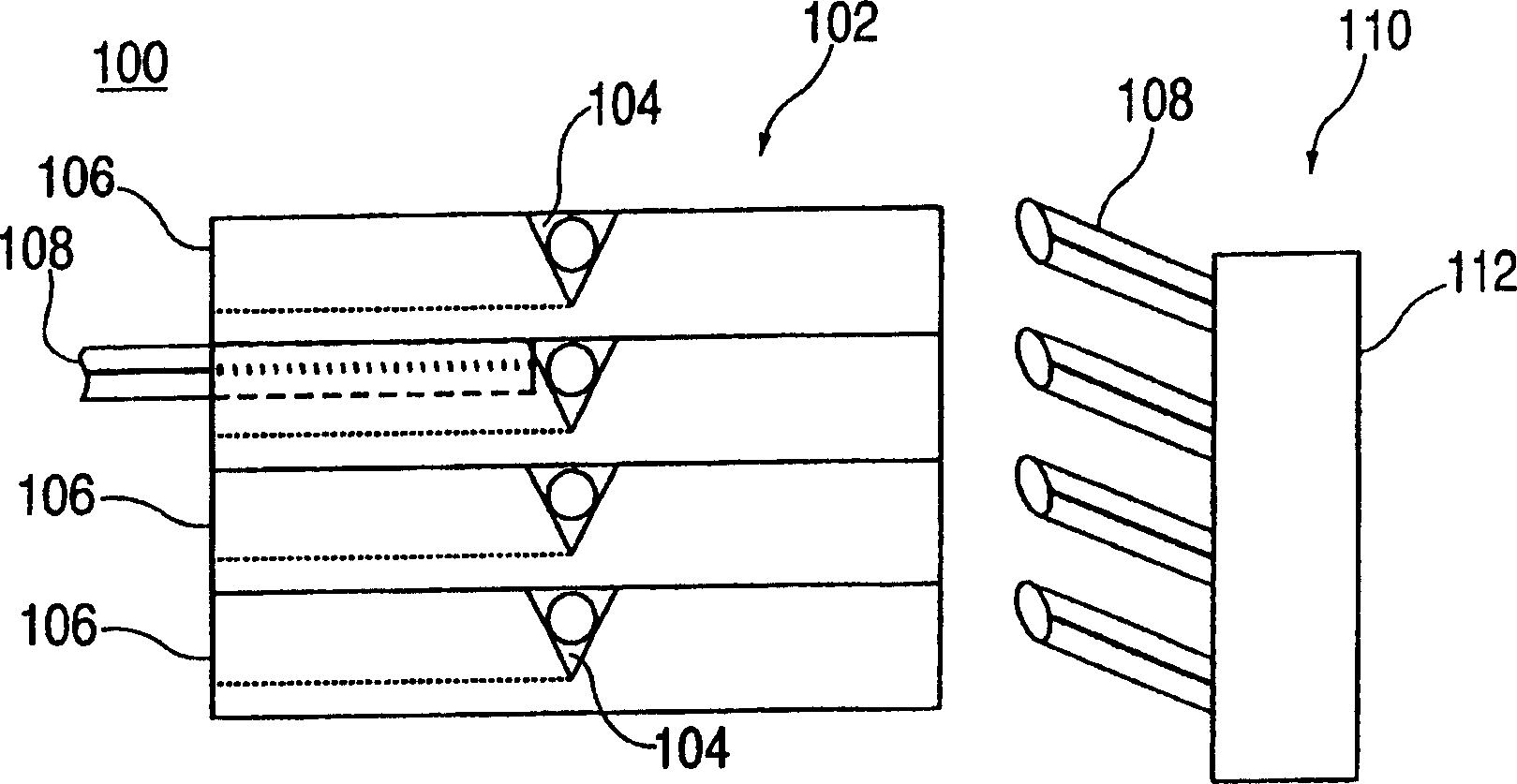

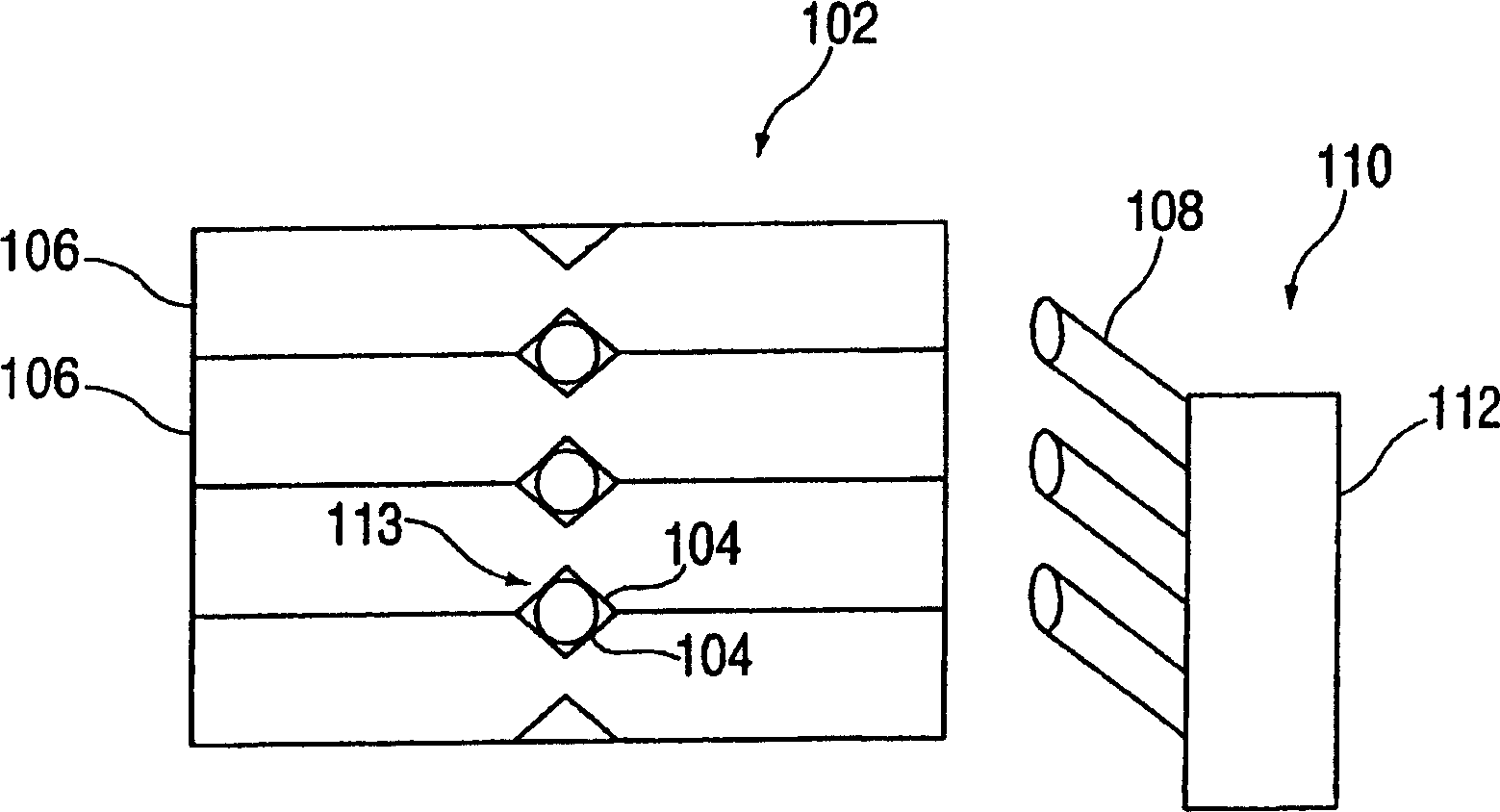

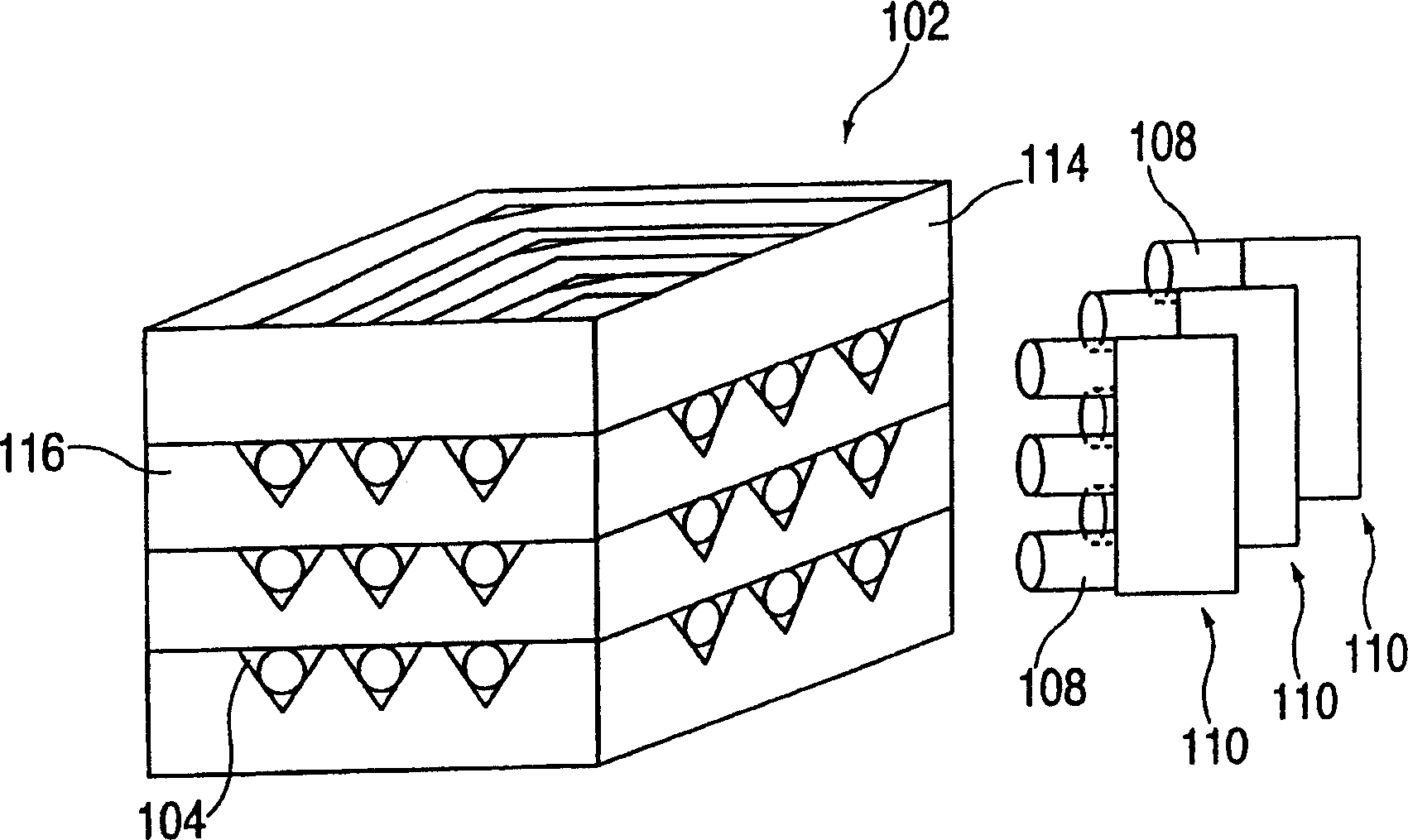

[0018] First refer to figure 1 , which shows a ferruleless optical connection device 100 suitable for use in an optical backplane connection system according to an embodiment of the present invention. The device 100 includes a stacked silicon stack assembly 102 having a plurality of light guide housing components in figure 1 V-shaped grooves 104 are formed in each successive layer 106 of the laminated assembly 102 . Each trench 104 may be formed within silicon stack assembly 102 by a technique such as etching, and is configured to receive a single light guide (eg, optical fiber 108 ) inserted therein. It should be noted that the optical fiber 108 is inserted within a single groove 104 without the use or presence of a ferrule or other cylindrical plug attached thereto. Furthermore, the optical fibers 108 are substantially cantilevered in free space prior to insertion into the stack 102, and alignment is achieved therein by the V-grooves 104 themselves.

[0019] In particular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com