Water-soluble propenoic-acids adhesive and its preparation method, ceramic slurry composition and preparation method thereof

An acrylic, ceramic slurry technology, applied in the direction of acidic copolymer adhesives, adhesive types, ceramic layered products, etc., can solve the problem of reducing the tensile strength and elongation of ceramic green sheets, reducing dryness, etc. problem, to achieve the effect of shortening drying time and good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

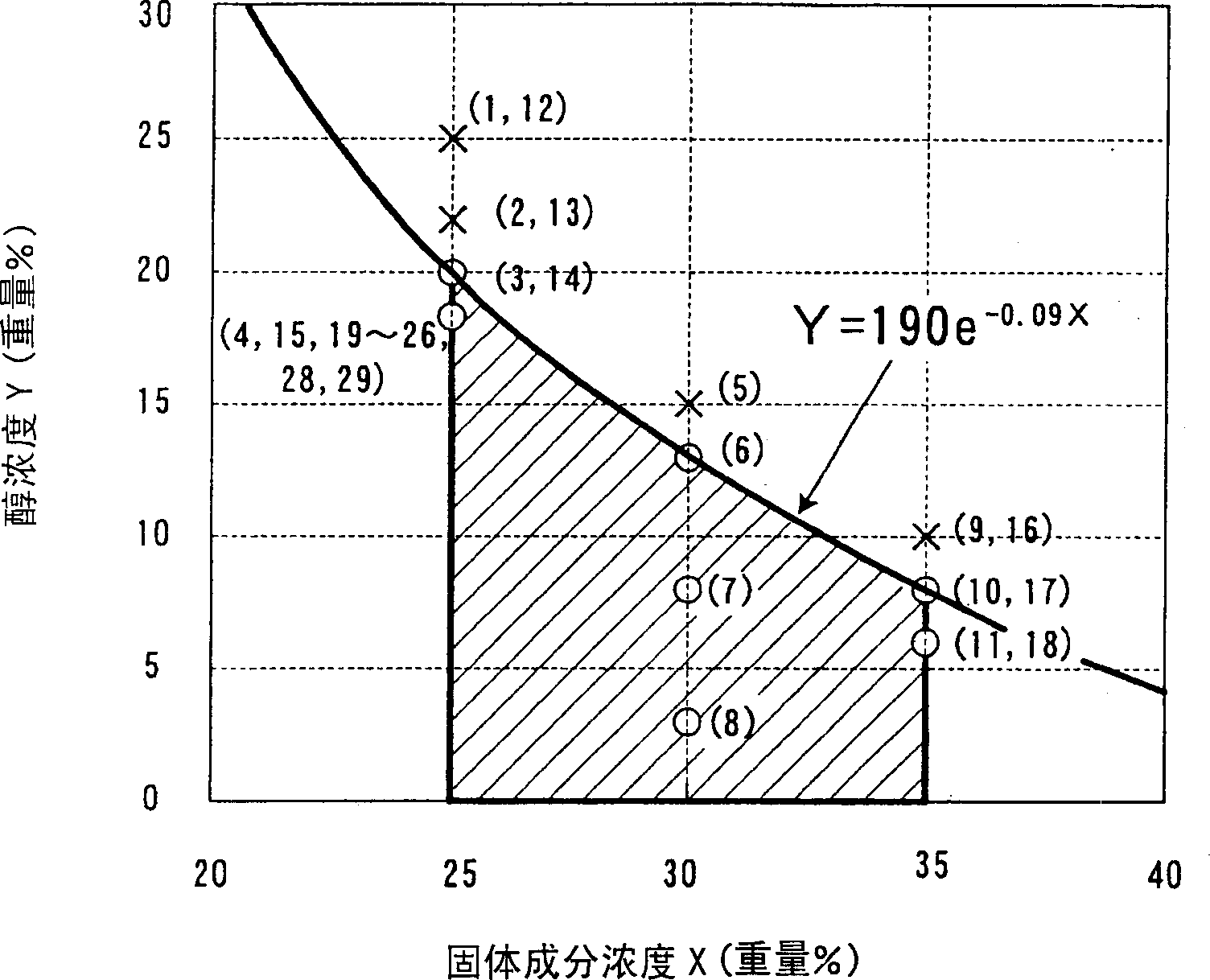

[0081] (Samples 1 to 18)

[0082] First, weigh barium carbonate (BaW 3 ) and titanium oxide (TiO 2 ), after wet mixing with a ball mill, dehydration and drying. Thereafter, it was calcined at 1000° C. for 2 hours, and then pulverized to obtain ceramic raw coal powder.

[0083] A water-soluble acrylic adhesive was obtained as follows.

[0084] In a 1-liter separable flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel and an introduction tube, 230 g of methanol and 35 g of pure water were charged, and 0.42 g of a polymerization initiator AIBN (α-α' azo Diisobutyronitrile), heated to 65°C under nitrogen flow.

[0085] Acrylic acid, which is an unsaturated monomer containing carboxylic acid, and methyl acrylate, which is an alkyl acrylate, are as shown in "Acrylic Acid Amount [% by Weight]" in Tables 1 to 5. Regarding Samples 1 to 11, the former 1.0 g and the latter were mixed at a ratio of 99.0, and about samples 12 to 18, the former was mixed...

Embodiment 2

[0171] Example 2 is an experiment conducted to evaluate the influence of pH on a solid-containing water-soluble acrylic adhesive and the influence of pH on the obtained ceramic slurry composition.

[0172] First, weigh barium carbonate (BaCO 3 ) Titanium oxide (TiO 2 ), after wet mixing with a ball mill, dehydration and drying. Thereafter, it was calcined at 1000° C. for 2 hours, and then pulverized to obtain a ceramic raw material powder.

[0173] A water-soluble acrylic adhesive was obtained as follows.

[0174] In a 1-liter separable flask equipped with a stirrer, a thermometer, a reflux condenser, a dropping funnel and a gas inlet tube, add 200 g of methanol and 50 g of pure water, and at the same time, add 2 g of the polymerization initiator azobis(4-cyanovaleric acid) , heated to 65 °C under nitrogen atmosphere.

[0175] In addition, 5.0 g of acrylic acid as an unsaturated monomer containing carboxylic acid and 95.0 g of methyl acrylate as an alkyl acrylate were mixe...

experiment example 3

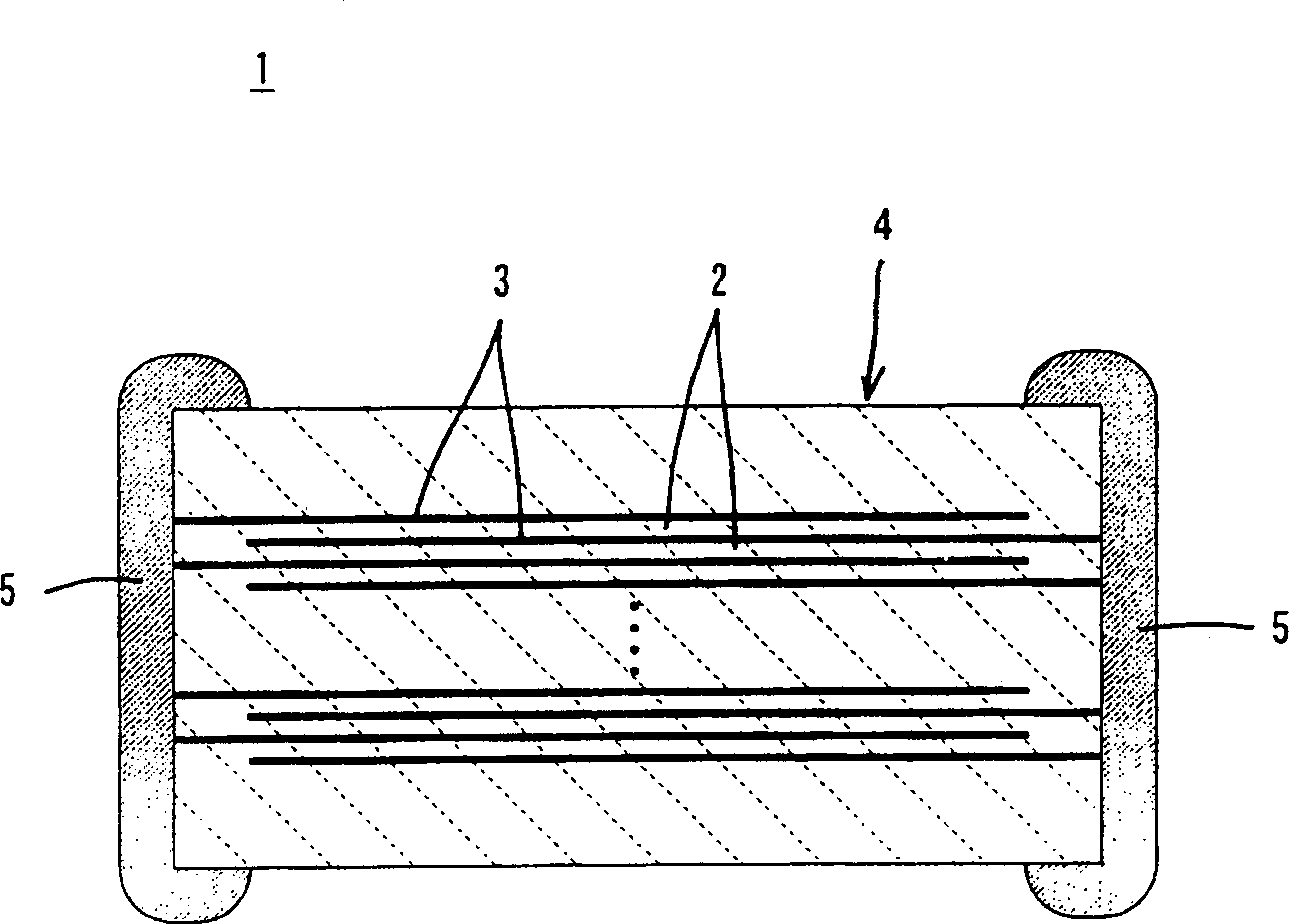

[0190] In Experimental Example 3, the ceramic slurry composition made in the above-mentioned Experimental Examples 1 and 2, within the scope of the present invention, is used as a laminated ceramic electronic component to make a figure 2 Multilayer ceramic capacitor 1 of the structure shown.

[0191] Using the ceramic slurry composition of the invention, process a ceramic green sheet with a thickness of 10 μm by doctor blade method, and then dry the ceramic green sheet at 80° C. for 5 minutes. This ceramic green sheet is figure 2 Dielectric ceramic layer 2 formed in .

[0192] Next, an electroconductive paste film was formed by printing an electroconductive paste on a specific main surface of the ceramic green sheet, and then, the electroconductive paste film was dried at 80° C. for 10 minutes. This conductive paste film is figure 2 The conductive film formed in the internal electrode 3.

[0193] Next, 200 ceramic green sheets on which a conductive paste film was formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com