Heater controller of drier

A control device and heating device technology, which is applied in the direction of dryers, drying, lighting and heating equipment, etc., can solve the problems of unable to adjust the output power of the heater, increase the production cost, and unreasonable structure of the heat sink, so as to reduce production Effects of cost reduction, area reduction, and improvement in power usage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Hereinafter, the dryer designed in the present invention will be described in detail with reference to the accompanying drawings.

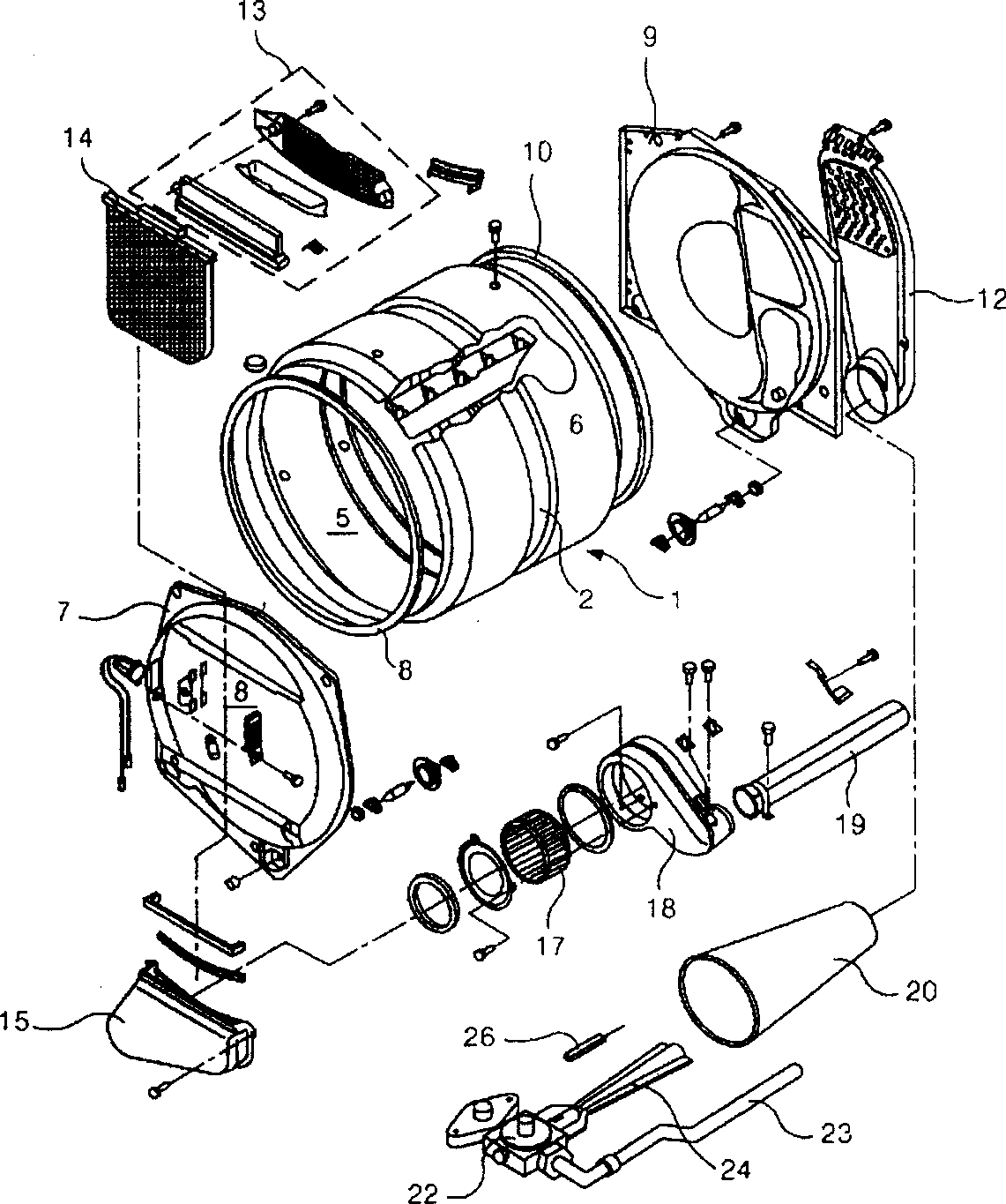

[0044] image 3 and Figure 4 It is the structural diagram of the dryer designed by the invention.

[0045] Depend on image 3 , Figure 4 As shown, the casing 53 constitutes the appearance of the dryer. And the front panel 41 forming the front part of the dryer is provided at the head end of the casing 53 . Inside the cabinet 53, the drum 44 that dries the laundry while rotating is provided. The drum 44 is driven to rotate by a drum driving belt 54 wound around its periphery. An exhaust port 43 opening to the inside of the drum 44 is formed on the inner surface of the front panel 41 . The main function of the exhaust port 43 is to discharge the air inside the cylinder 44, and a linen filter 36 for removing impurities in the air is provided at its entrance.

[0046] An electrode sensor 38 for detecting the dryness of the laundry ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com