Traction continuously variable transmission device, split-power transmission system and apparatus using same

A technology of transmission system and transmission device, which is applied in the direction of transmission device, friction transmission device, mechanical equipment, etc., and can solve problems such as design restrictions, application restrictions, PSTS difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

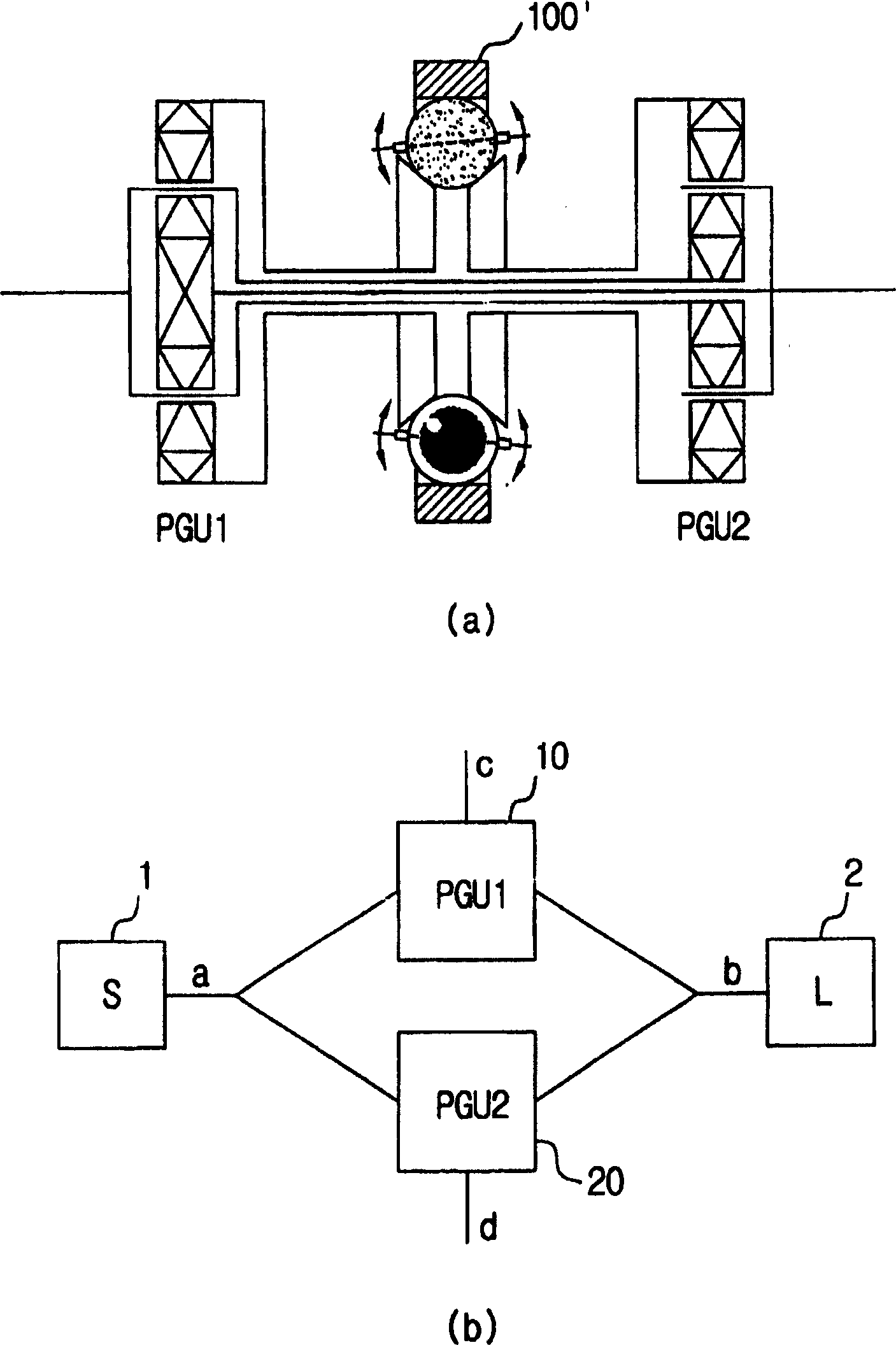

[0029] Figures 1 to 3 It has been explained when describing the prior art. Figures 4 to 13 Description A traction drive continuously variable transmission (CVT) using a four bar crank mechanism and spherical rotors according to one aspect of the invention. A traction drive CVT apparatus using a spherical rotor (friction wheel) in which one spherical surface contacts the other spherical surface will be described below, but the present invention is not limited to this embodiment. It should be pointed out that, according to the present invention, it is possible to configure a counter-rotating rotor assembly, that is, relying on the driving rotor and driven rotor of the four-bar crank mechanism, using friction wheels instead of spherical rotors, these friction wheels have various types of contact surfaces, For example, typical flat frict...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap