Low temperature valve device

A valve device, cryogenic valve technology, applied in the direction of valve device, valve operation/release device, lift valve, etc., can solve the problems of mixing, pneumatic fluid penetration, undesired mixture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

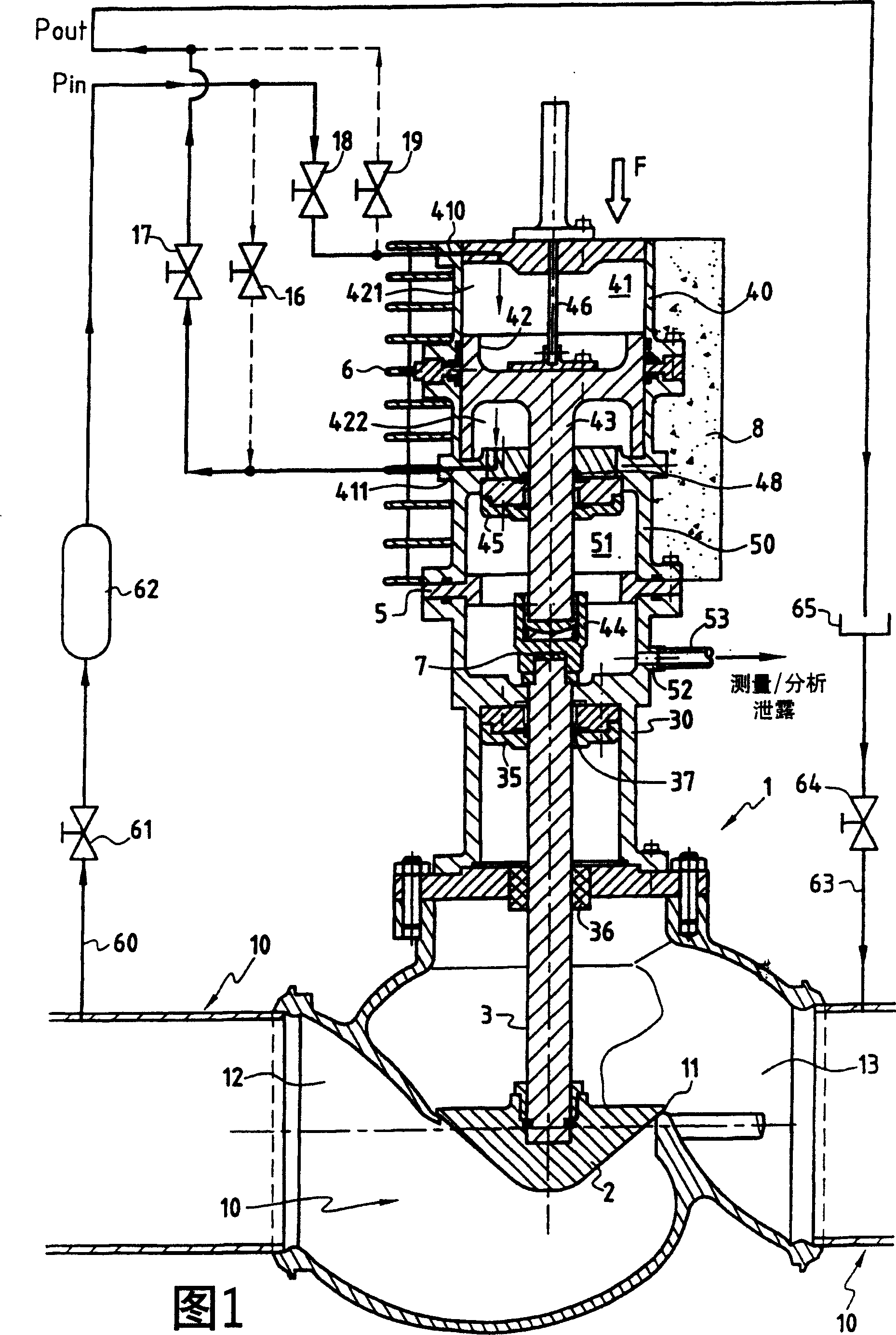

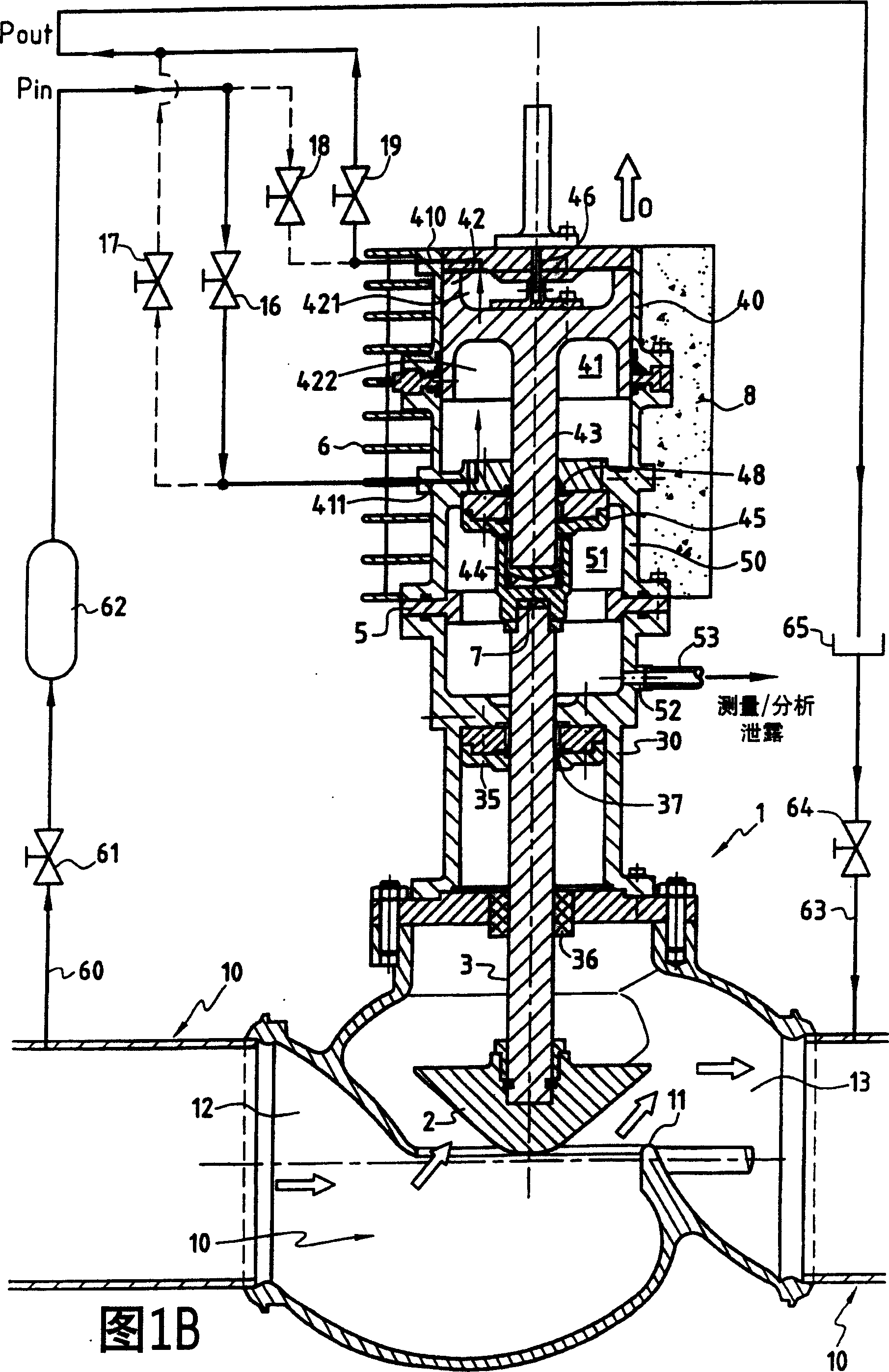

[0032] In a first embodiment of the present invention, FIG. 1A shows a valve device comprising a valve body 1 constituted by a pipe 10, and a housing 30 fixed to the upper part of the pipe in which cryogenic fluid flow. The conduit 10 comprises an upstream part 12 and a downstream part 13 separated by a valve element 2 . The valve element 2 is connected to a control rod 3 which slides vertically in guide supports 35 and 36 to move the valve element 2 between a closed position and an open position in which the valve element rests against the Formed on the pipe is a seat 11 above which the valve element is raised vertically in the open position (FIG. 1B). This will allow cryogenic fluid to flow along the pipe to be controlled.

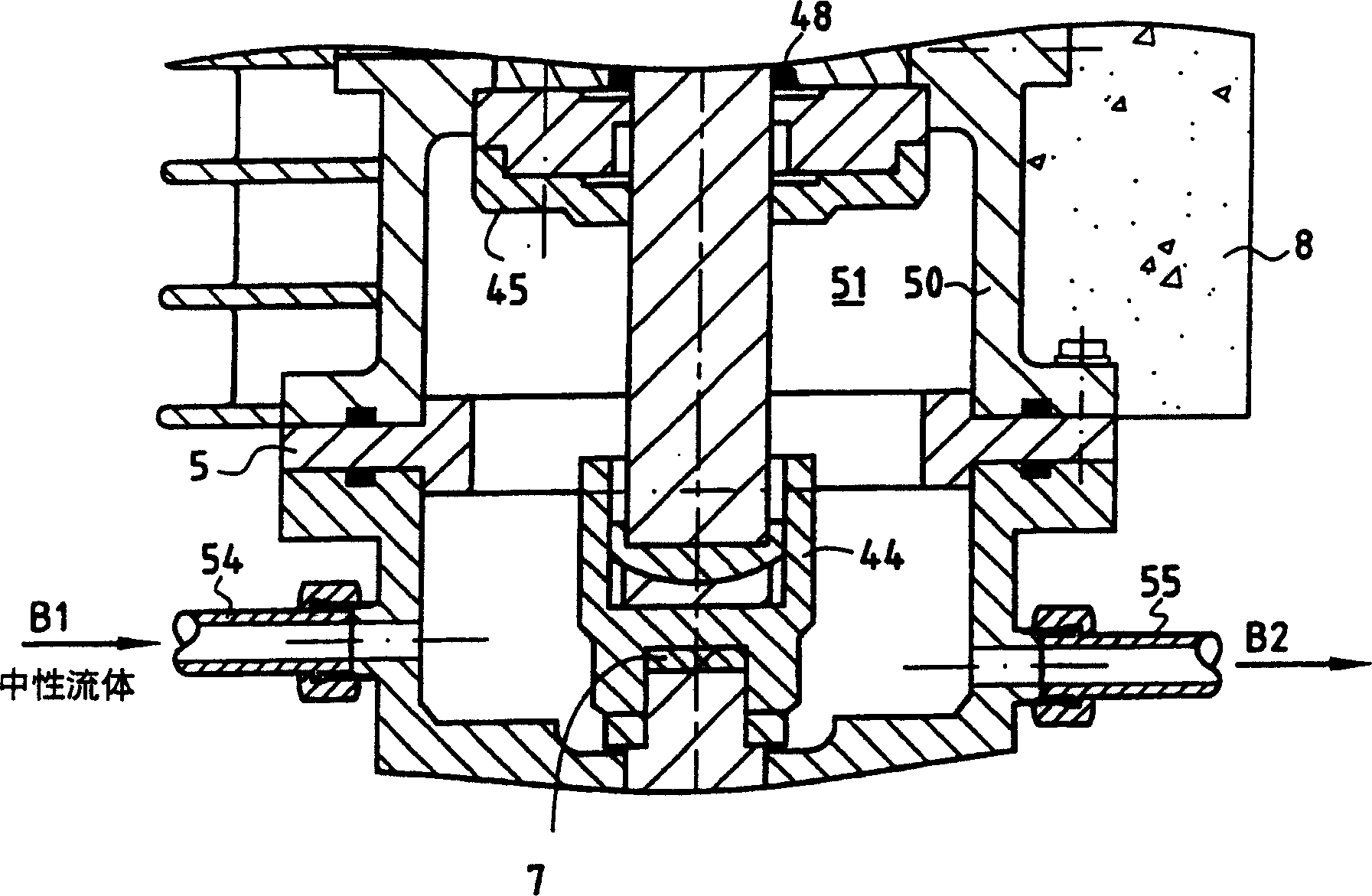

[0033]To transmit the control movement to the control rod 3 , the valve arrangement includes a pneumatic actuator 4 . The actuator 4 is formed by a housing 40 which delimits a chamber 41 in which a piston 42 is movable.

[0034] The piston 42 defines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com