Flow diagnostic system

A technology for diagnosing systems and flow, applied in variable sampling systems, flow control, general control systems, etc., to solve problems such as reducing reliability and increasing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

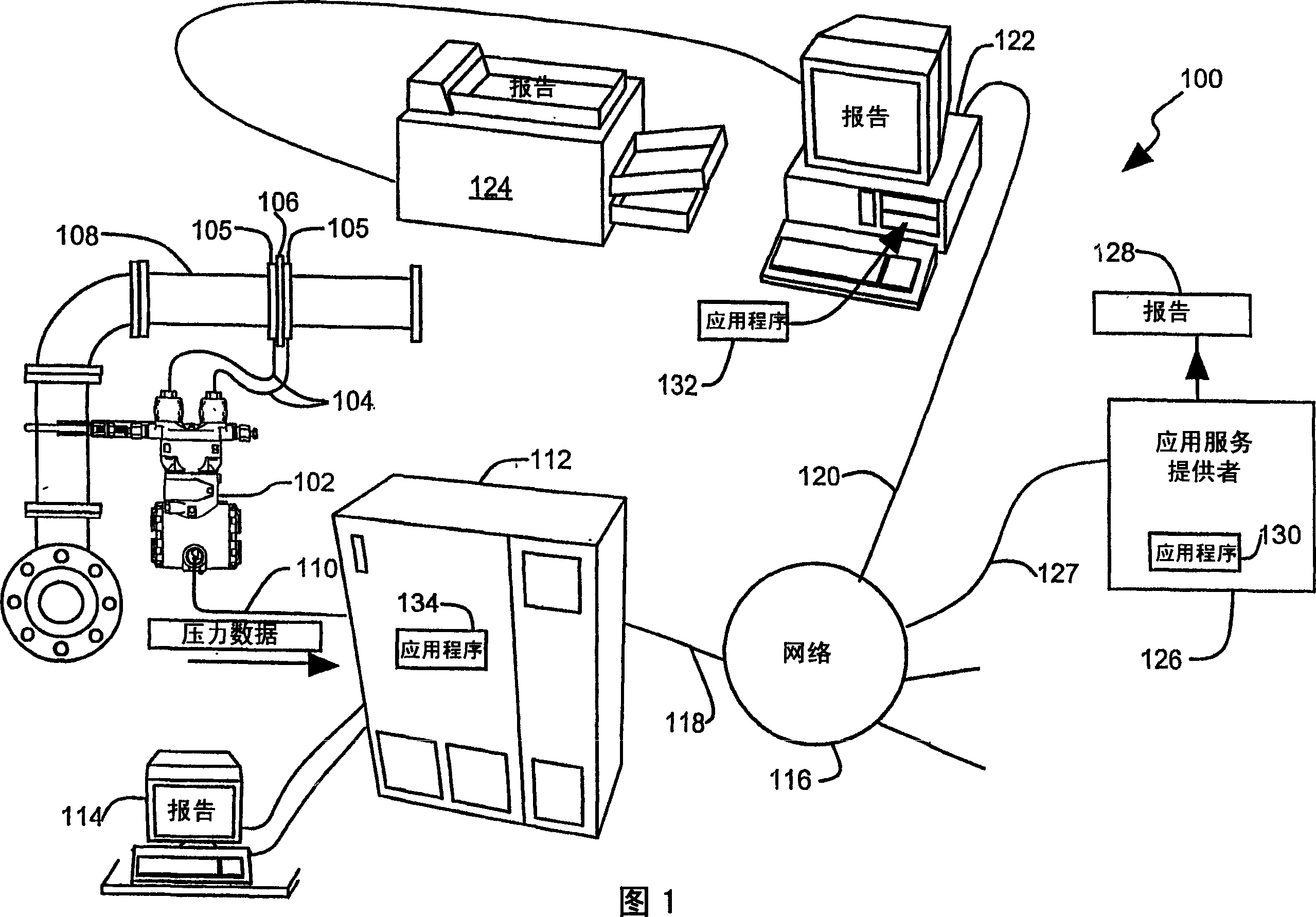

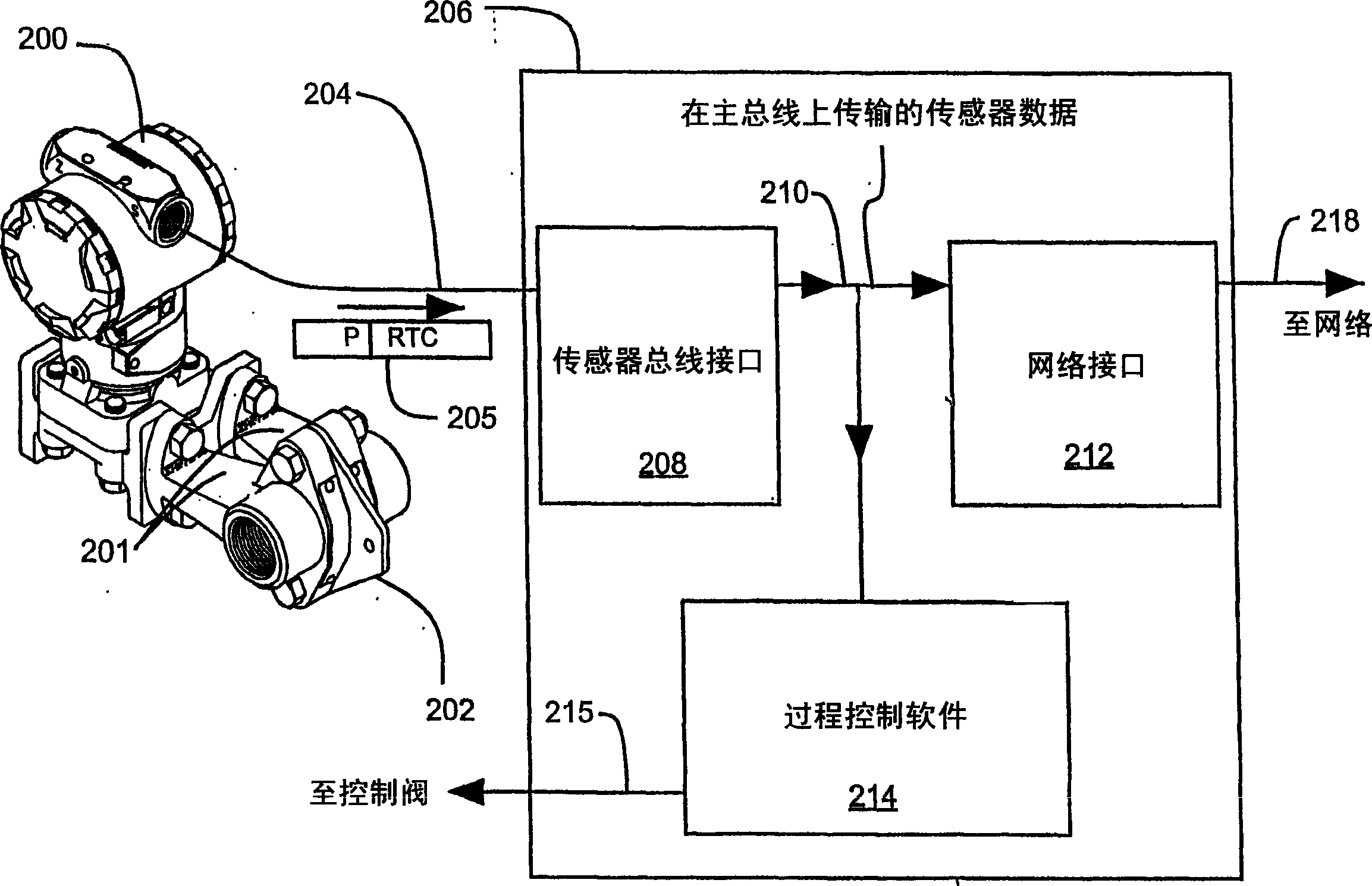

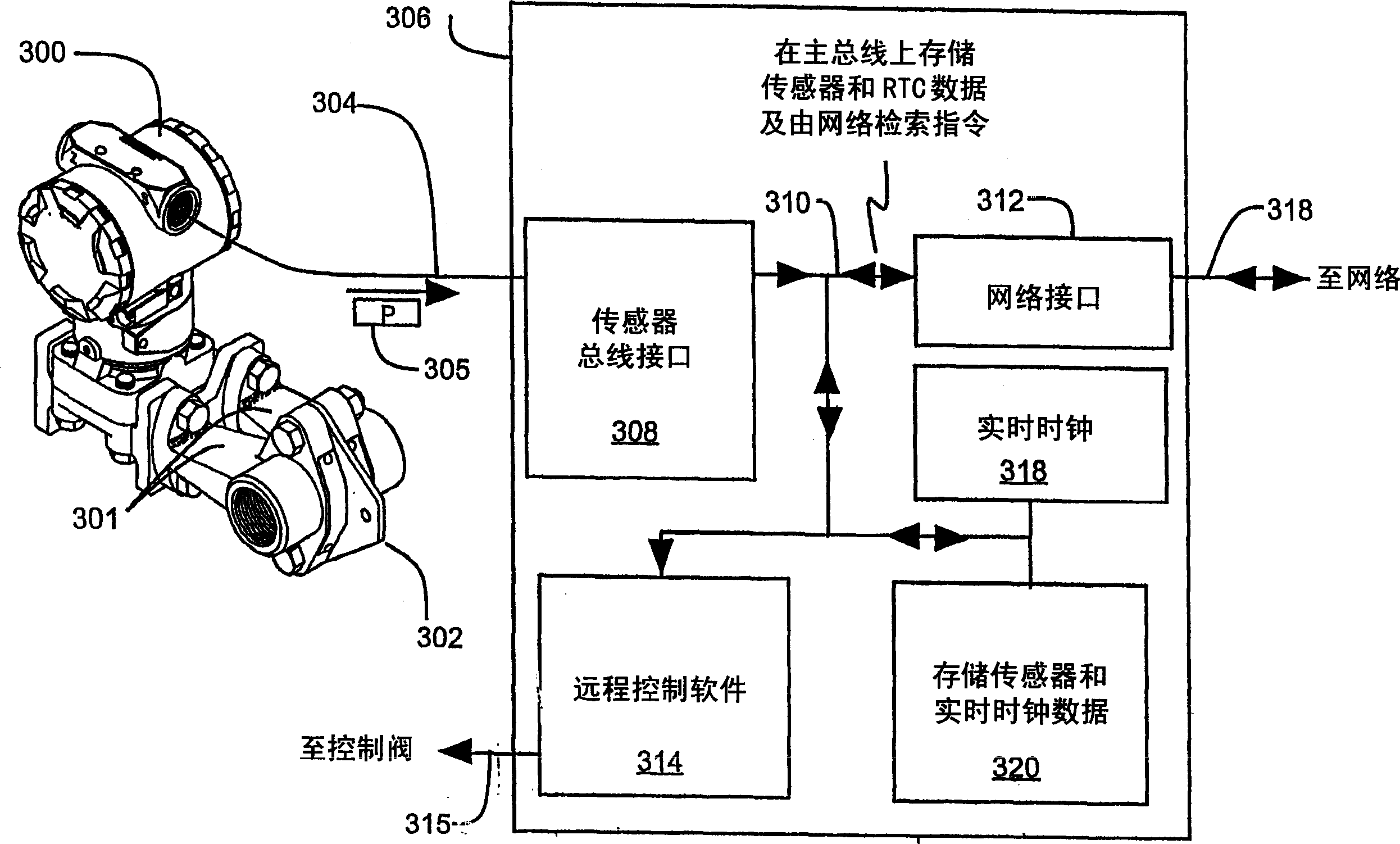

[0028] The flow diagnostic system provided by the present invention can diagnose the impulse transmission line and / or the main component connected with the pressure sensor. The diagnostic application can be downloaded from an Application Service Provider (ASP) over a network, or obtained from a computer readable medium such as a CD-ROM or diskette. Diagnostic applications can run on the control system, remote computer or ASP and provide diagnostic reports. Diagnostic applications can run on a higher-power processor than the lower-power processor built into the pressure sensor. The application of high-performance processors allows complex diagnostics to be performed in real time, providing rapid reports to plant operators on the condition of primary components, impulse transmission lines, or both. The processor built into the sensor does not require processing time for diagnostics and thus performs its measurement tasks quickly.

[0029] 1 is a block diagram of a general exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com