Integral winding stator coil assembly of rotating machine

A technology of stator coils and concentrated windings, applied in windings, electric components, manufacturing motor generators, etc., can solve problems such as difficulties, and achieve the effect of easy fixing and suppressing the increase of losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

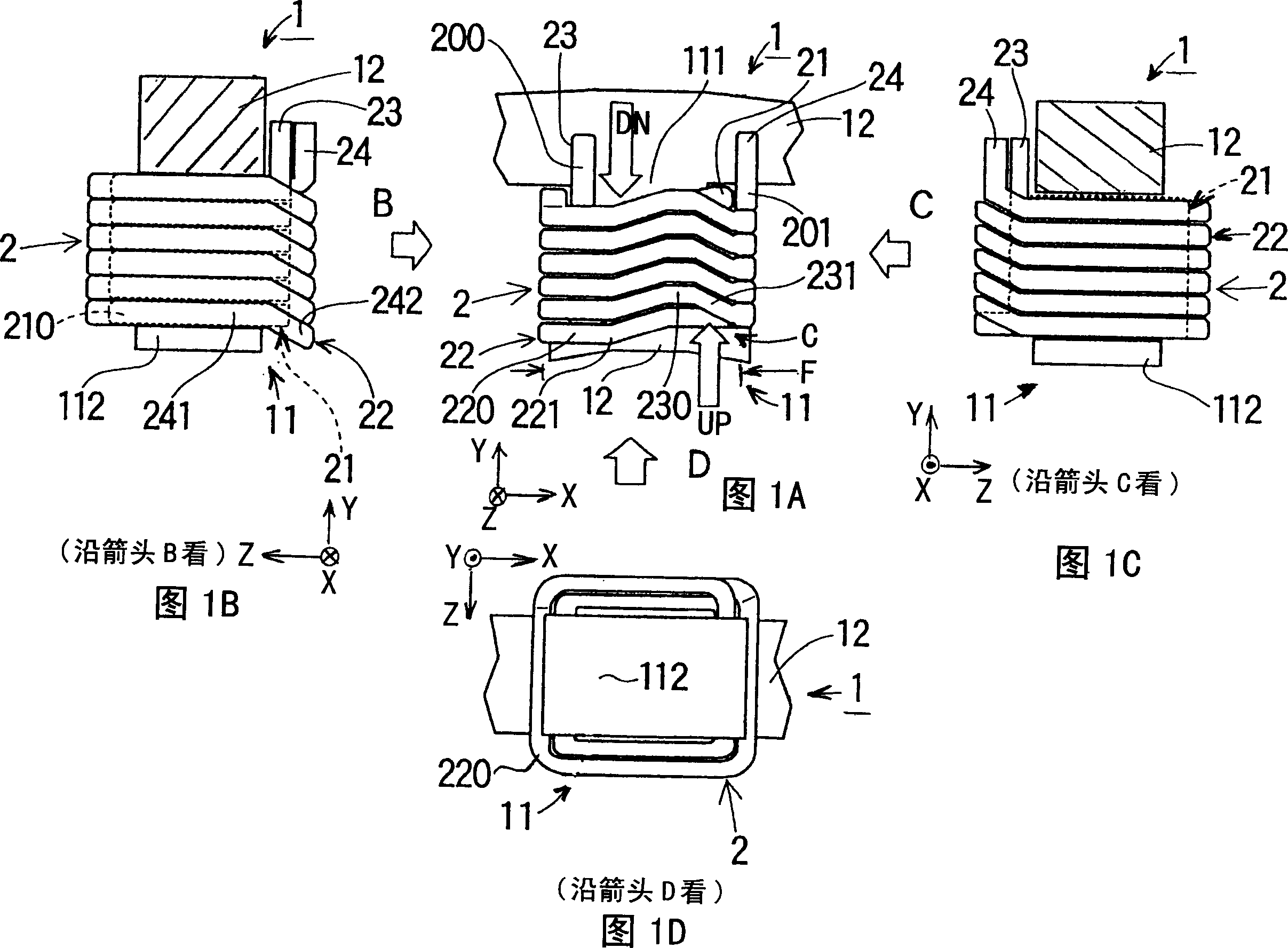

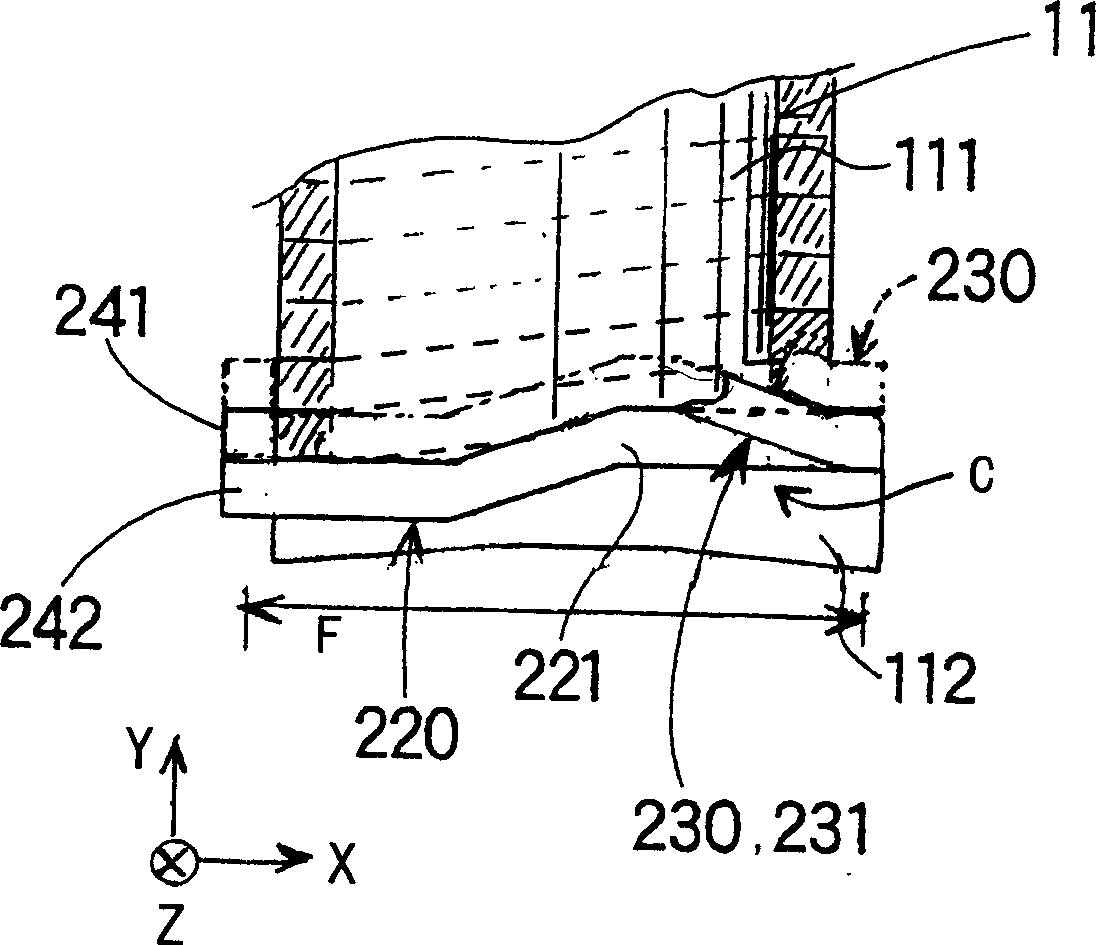

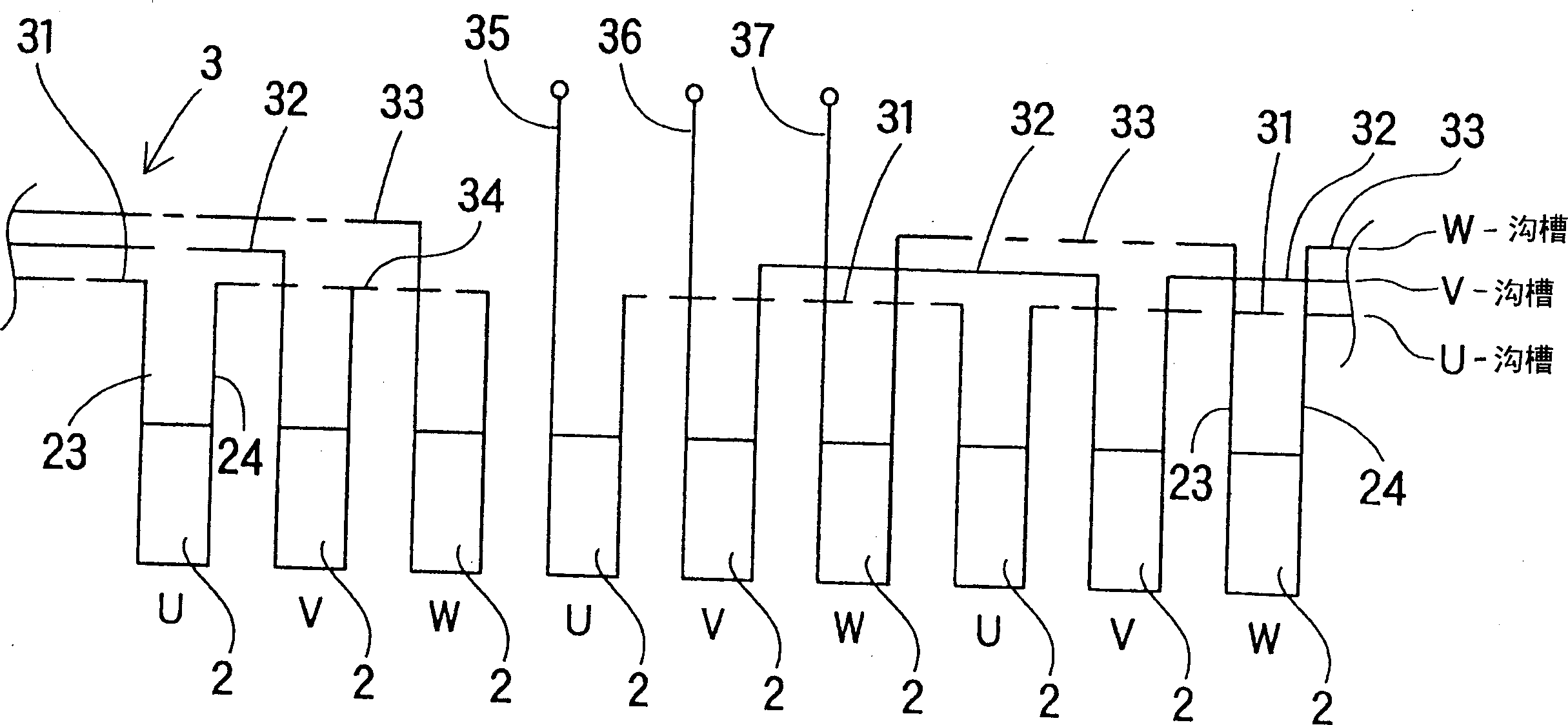

[0036] A first embodiment of a concentrated winding type stator coil assembly according to the present invention included in a rotating electrical machine will now be described with reference to FIGS. 1 to 7 .

[0037] 1A to 1D are partially shown from various directions equipped with a stator core 1 and teeth 11 formed protruding from the stator core 1 (only one tooth 11 is shown). A coil 2 is wound around each tooth 11 to form a tooth-wound coil called a "tooth coil". In these figures, FIG. 1A shows the coil group seen in the axial direction of the stator core 1, and FIGS. 1B and 1C show the sides of the coil group seen in the directions indicated by arrows B and C, respectively. view, and FIG. 1D is a bottom view of the coil set seen along the direction indicated by arrow D.

[0038] In FIGS. 1A to 1D , three orthogonal directions are defined so that, as shown in FIG. 1A , the axial direction of the stator core 1 (hereinafter referred to as "core axial direction") correspo...

no. 2 example

[0082] will now refer to Figure 8 , describes a concentrated winding type stator coil assembly according to a second embodiment of the present invention.

[0083] Specifically, the second embodiment describes a phase winding configured by connecting tooth coils in parallel with each other.

[0084] In the second and subsequent embodiments, the same reference numerals are given to the same or similar components in structure and / or function as in the description of the foregoing first embodiment, and detailed descriptions thereof are omitted.

[0085] In this example, if Figure 8 As shown, four ring bus bars 300 to 304 are used to form a three-phase star connection. These bus bars are composed of a W-phase bus bar 300 , a V-phase bus bar 301 , a U-phase bus bar 302 , and a neutral point bus bar 303 . Incidentally, the remaining components of the stator coil assembly according to the second embodiment are similar or identical to those of the first embodiment.

[0086]Althou...

no. 3 example

[0088] A concentrated winding type stator coil assembly according to a third embodiment of the present invention will now be described with reference to FIGS. 10A to 10D.

[0089] The stator coil group according to this embodiment is structurally similar or identical to the stator coil group described in the first and second embodiments, except that the tooth coil 2 is wound in another way. Specifically, in the present embodiment, the tooth coil 2 is produced so as to have the second layer type coil 22 in which only the lower bent portion is formed (refer to arrow DN in FIG. 10A).

[0090] As with the stator coil group shown in FIGS. 1A to 1D , FIGS. 10A to 10D are partially shown from various directions equipped with a stator core 1 and teeth 11 formed protruding from the stator core 1 (only one tooth is shown). 11) The stator core unit. The coil 2 is wound around each tooth 11 to form a tooth wound coil (tooth coil). In these drawings, FIG. 10A shows a coil group seen in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com