Switch gear

A technology for switchgear and housings, applied in the direction of electric switches, electric heating devices, electrical components, etc., can solve problems such as maintenance and management difficulties, increased sealing procedures, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

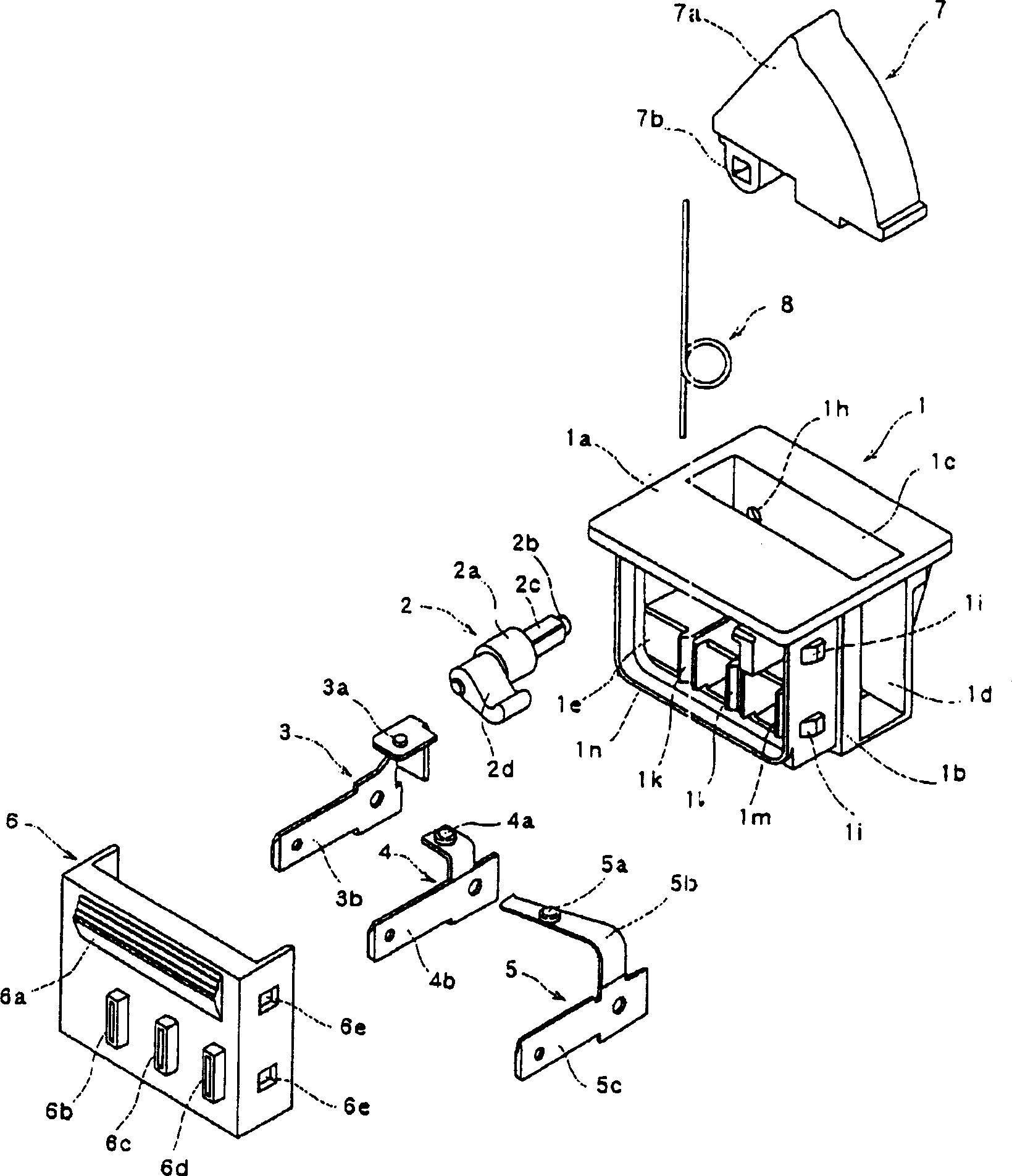

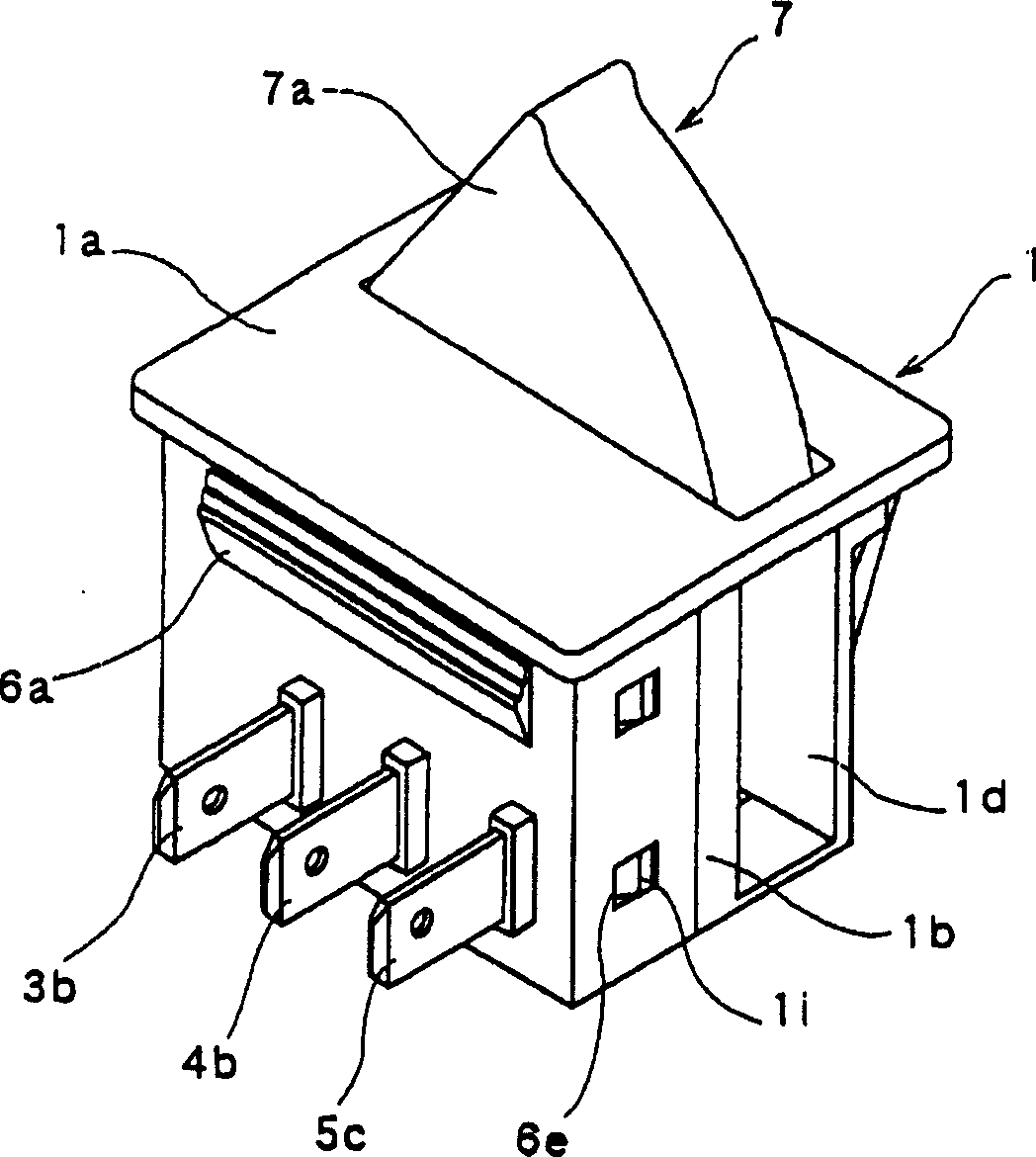

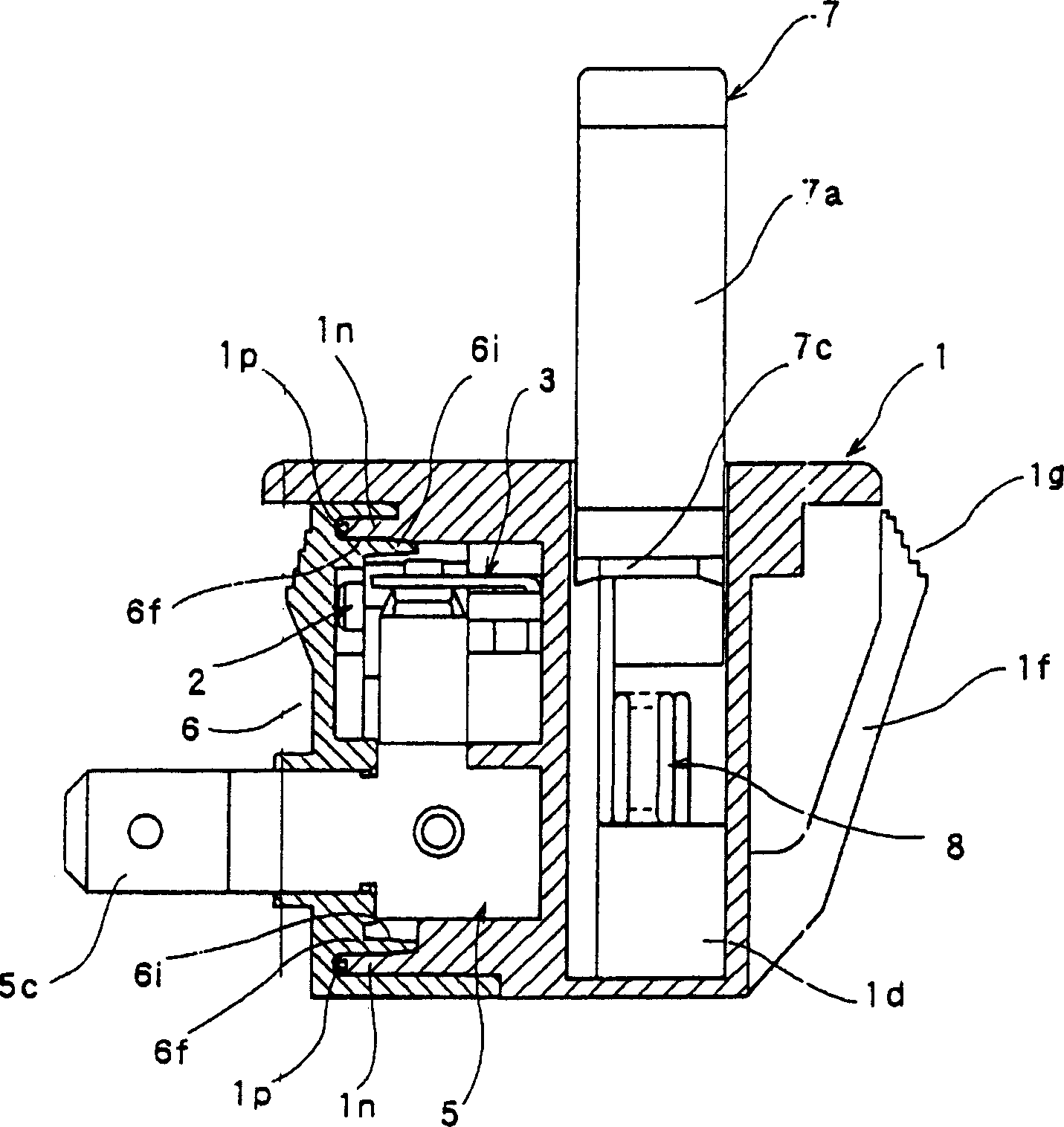

[0018] Below, the embodiment of the present invention is such as Figure 1 to Figure 6 shown. figure 1 is an exploded oblique view of the switchgear, figure 2 is the overall oblique view of the switchgear, image 3 is a cross-sectional view of the switchgear, Figure 4 It is a partial sectional view showing the fitting state of the case and the cover, Figure 5 It is a front view of the contact part showing the initial state, Image 6 It is a front view of the contact part showing the operating state.

[0019] In the figure, the casing 1 is formed in a roughly square shape from an insulating material such as synthetic resin, and is composed of a flat panel portion 1a and a base portion 1b connected to the panel portion 1a. A window portion 1c is formed on the upper surface of the panel portion 1a, and a lever 7 described later is rotatably inserted into the window portion 1c. Furthermore, an opening 1 d is provided which is continuous with the window 1 c and opens on on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com