Control device of yarn twisting machine

A control device and a technology for a twisting machine, which are used in spinning machines, continuously wound spinning machines, textiles and papermaking, etc., and can solve the problems of poor twist count accuracy and increased influence of twist counts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be described below using the drawings.

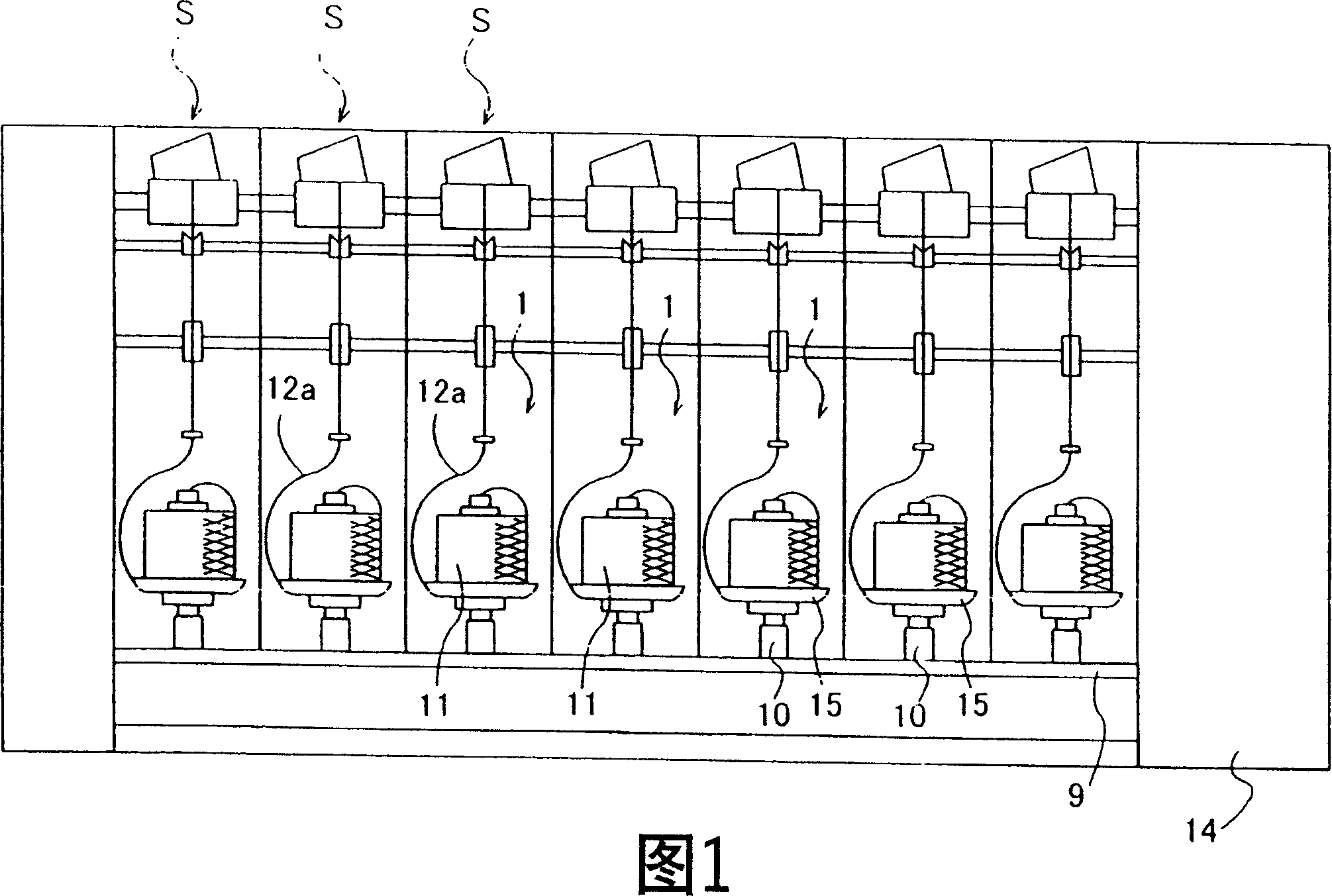

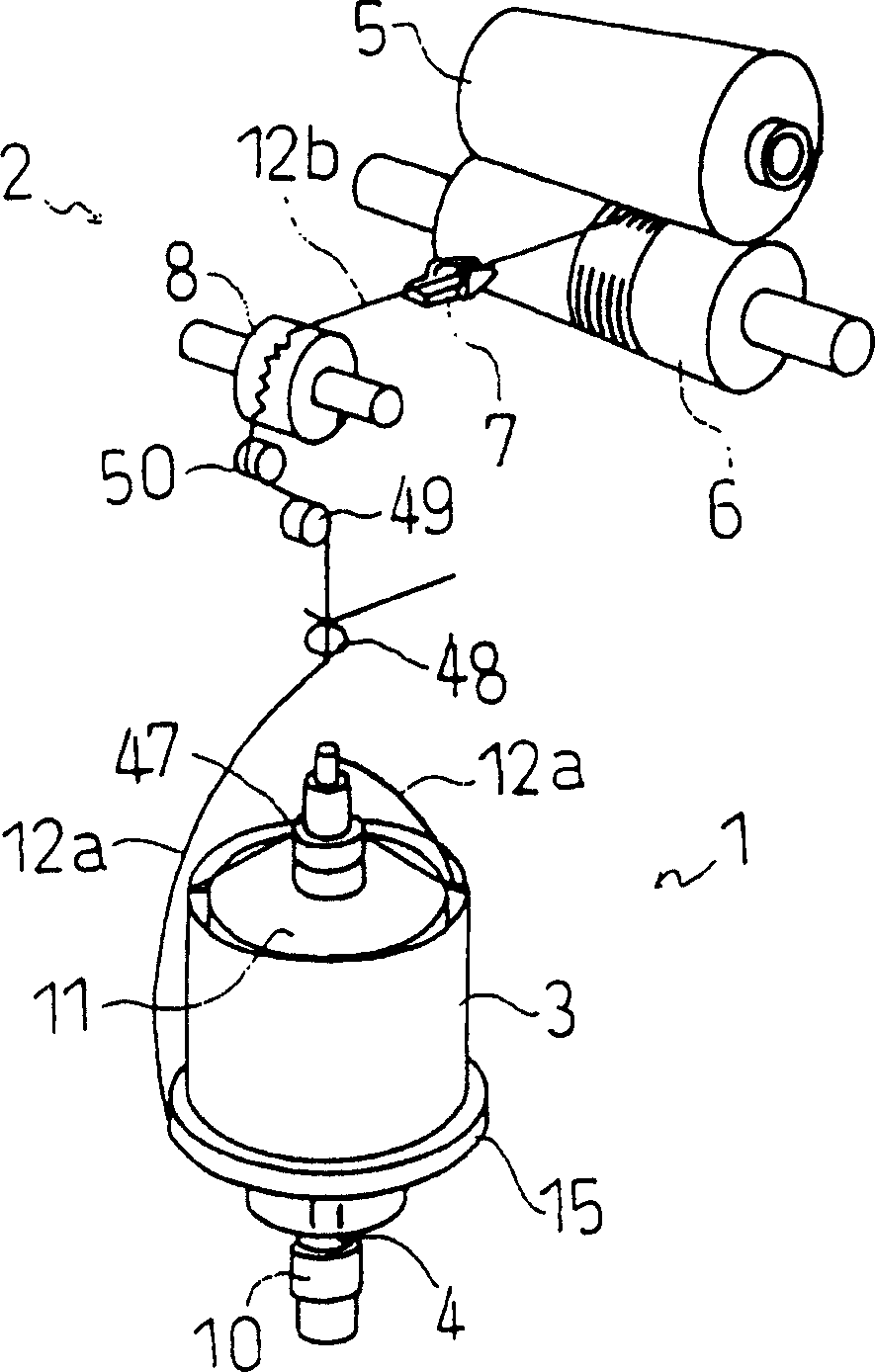

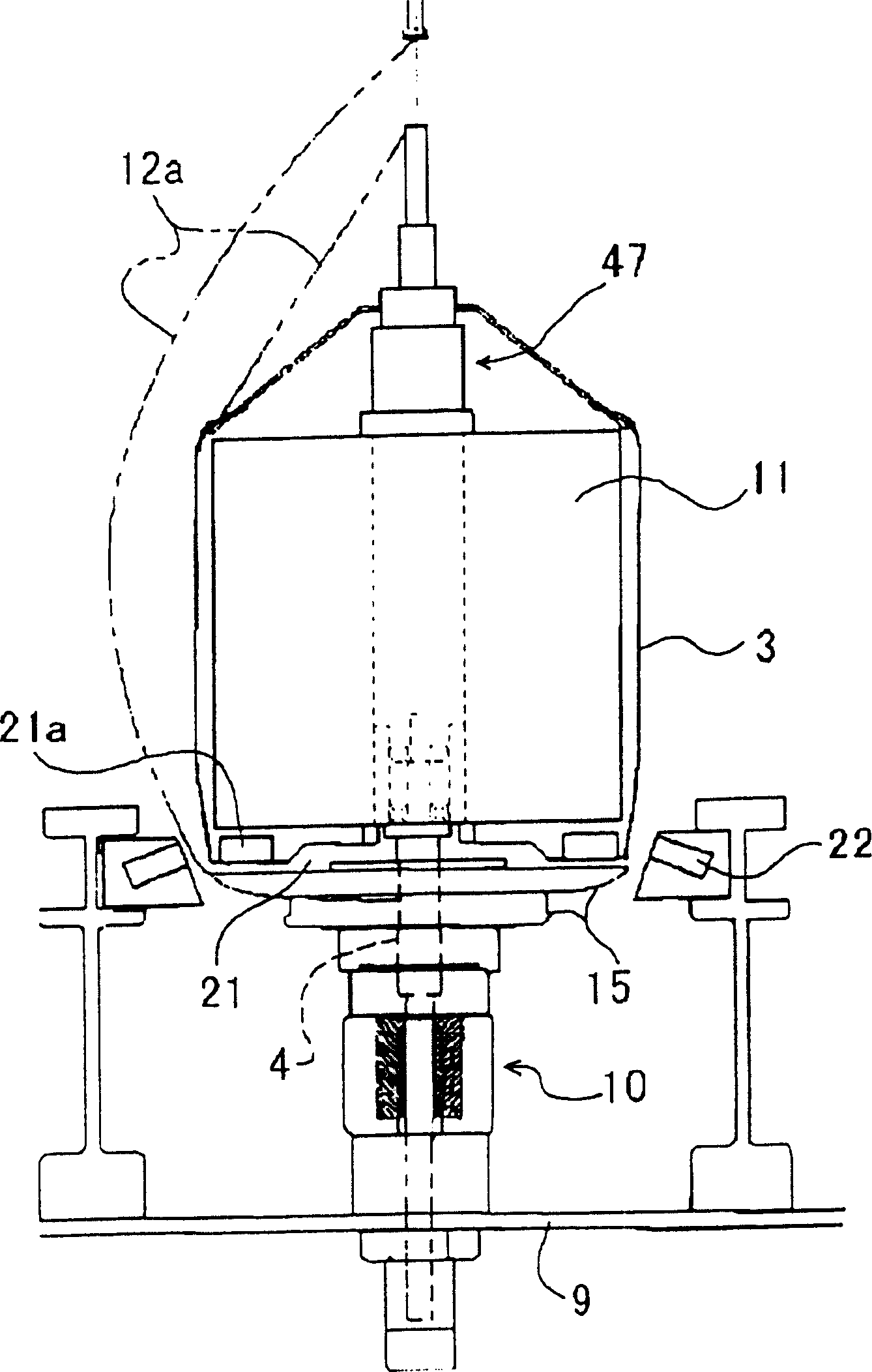

[0039] Fig. 1 is the whole front view that shows the single-spindle drive type twisting machine equipped with the control device of the present invention, figure 2 It is a perspective view showing the structure of one spindle of a single spindle drive type twister, image 3 It is a partial cross-sectional view showing the spindle device of the single-spindle-driven twister when viewed from the front, Figure 4 It is a block diagram showing the control device of the single spindle drive type twister, Figure 5 It is a graph showing the degree of deceleration and stop of the spindle drive motor and drum drive motor during deceleration and stop control. Figure 6 It is a perspective view showing a memory disc in a state where the hysteresis angle is large, Figure 7 It is a perspective view showing the storage disc in a state where the hysteresis angle is small.

[0040] Next, an embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com