Turbine nozzle segment cantilevered mount

A nozzle and plate segment technology applied in the field of cantilever-mounted nozzle segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

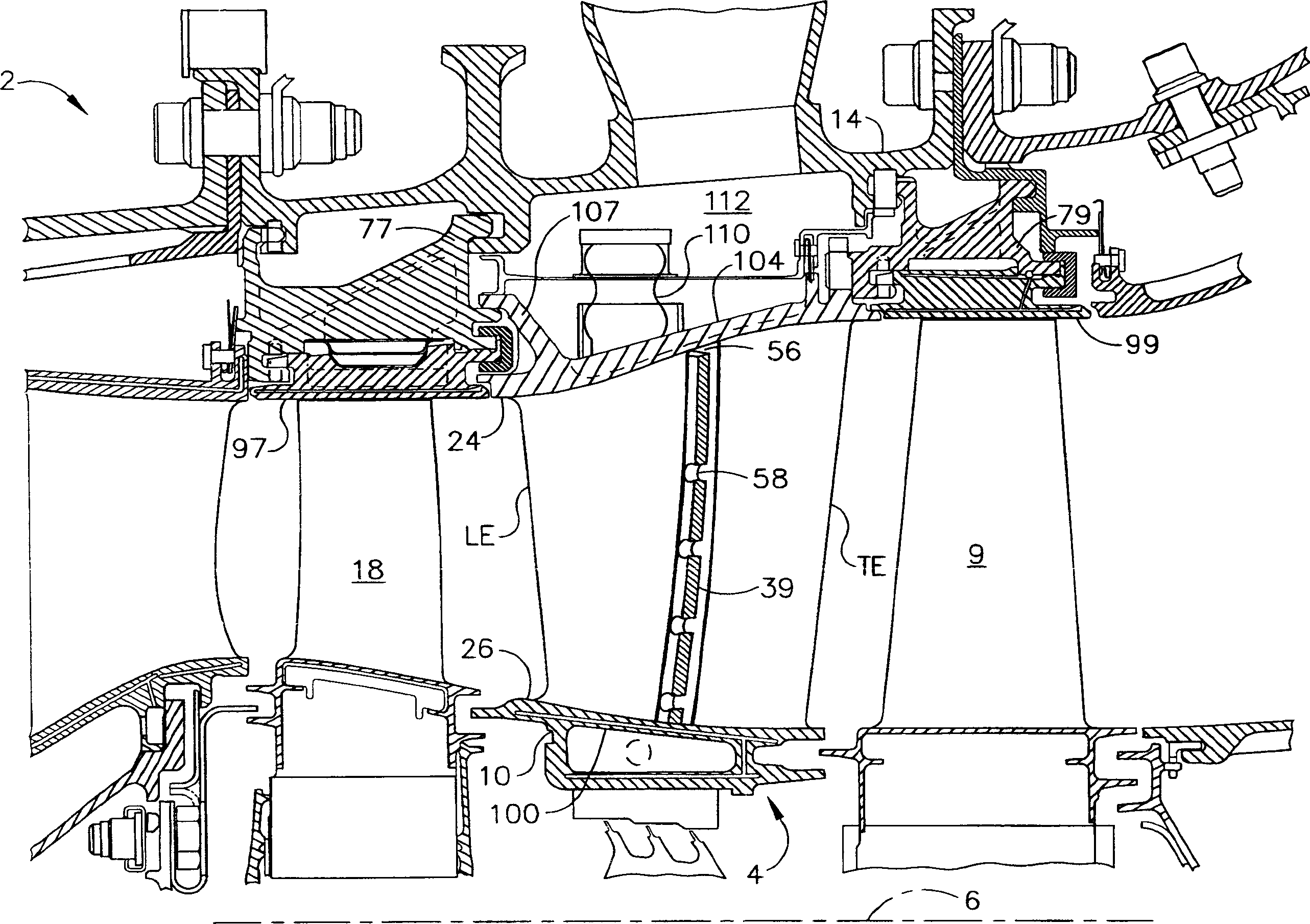

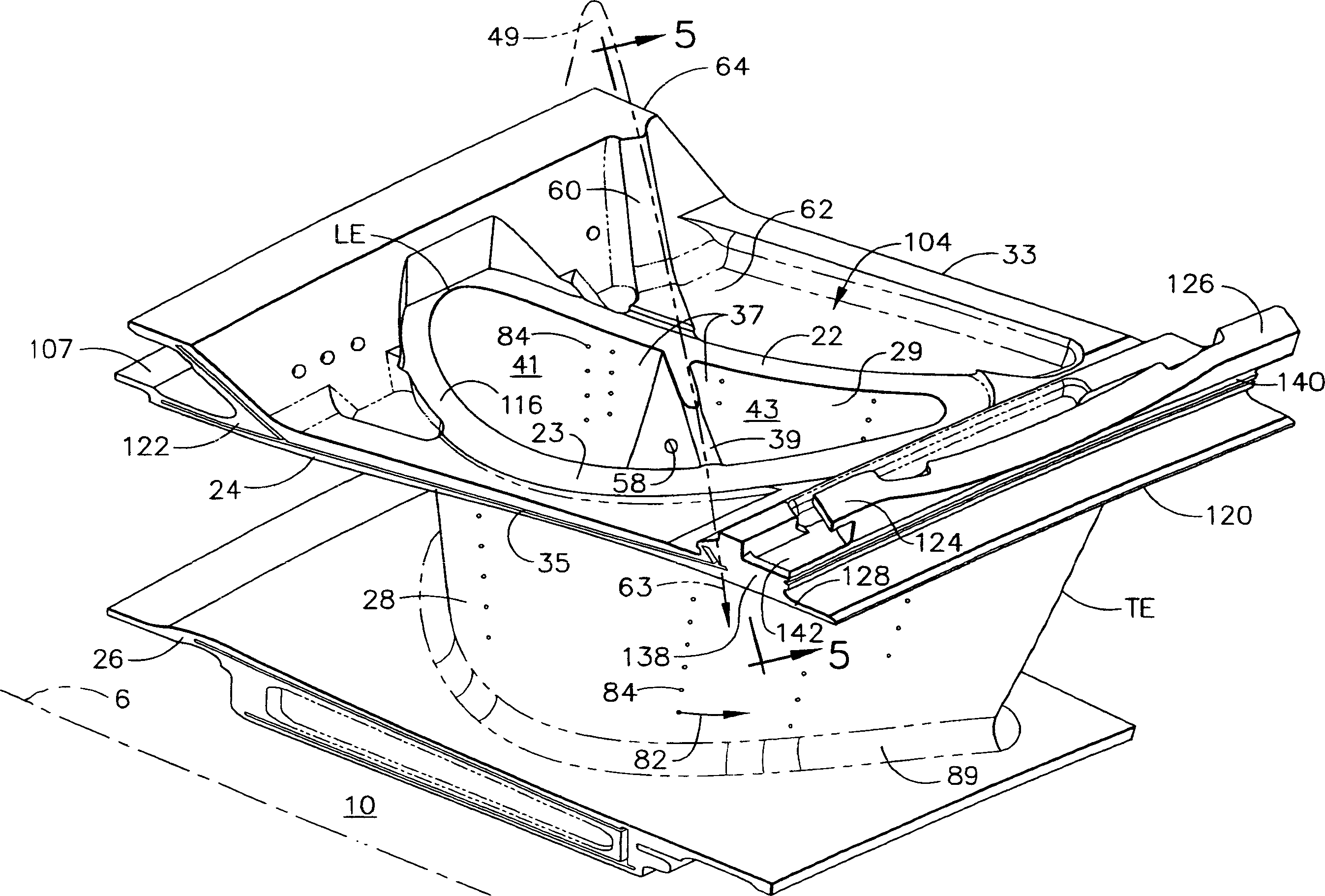

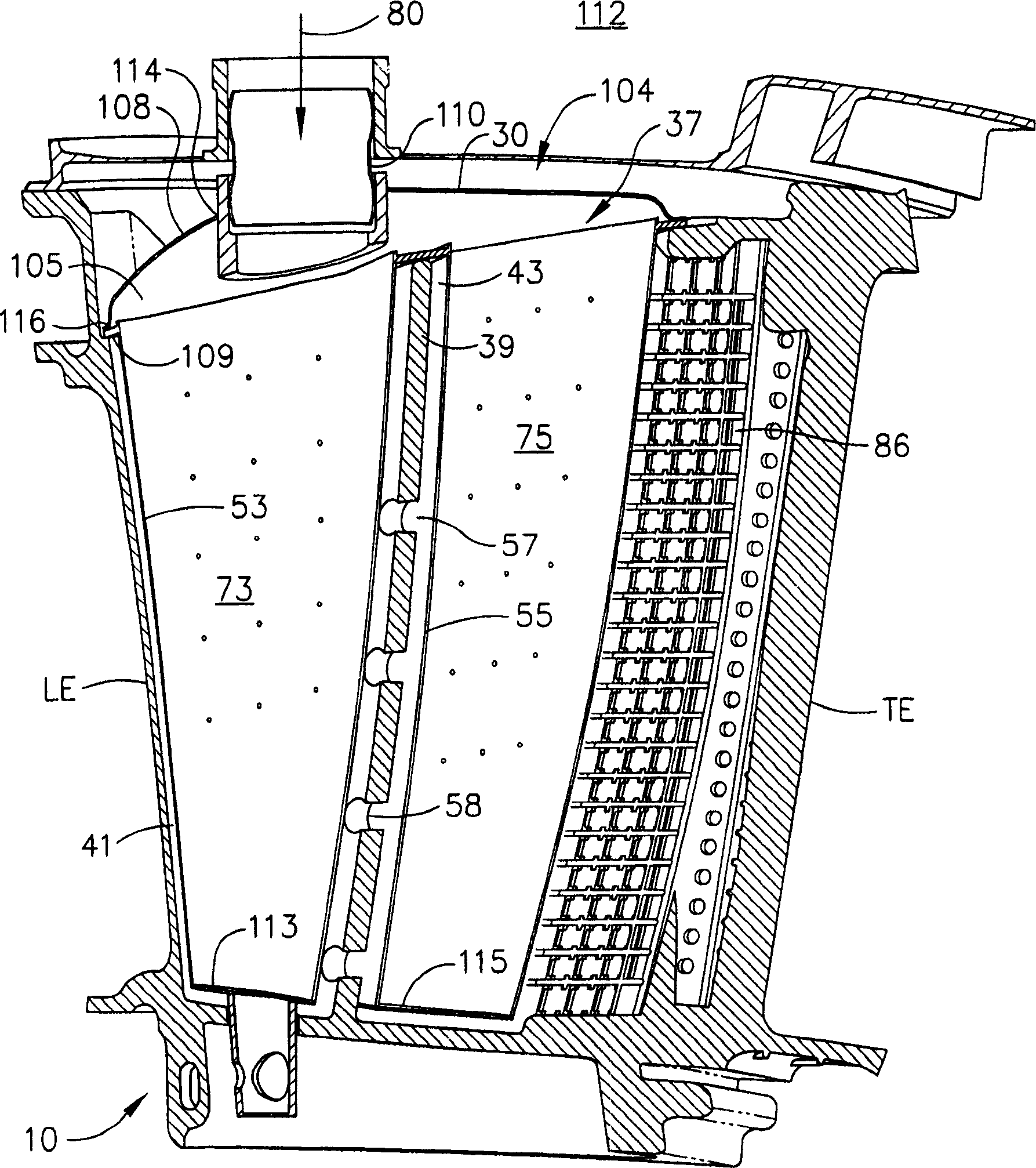

[0024] figure 1 An exemplary second stage turbine nozzle 4 of a high pressure turbine 2 of an aircraft gas turbine according to the present invention is shown in FIG. The nozzle 4 is arranged around a longitudinal or axial center axis 6 and comprises an annular housing 14 from which a plurality of nozzle segments 10 are mounted cantilevered. The nozzle section 10 is arranged between the rotor blades 18 of the first stage of the high-pressure turbine of the immediately upstream row and the rotor blades of the second stage of the turbine of the immediately downstream row 9 . First and second shrouds 97, 99 surround the first and second stage turbine rotor blades 18 and 9, respectively, and are supported by first and second shroud supports 77 and 79, which extend along the Radially inwardly is suspended by and connected to an annular housing 14 . The nozzle segment 10 is hooked to the first shroud support 77 by forward hooks 107 and cantilevered from the second shroud support 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com