Cooled tubes arranged to form impact type particle separators

A technology for separators and cooling pipes, which is applied in the field of improved impact particle separator structure, and can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

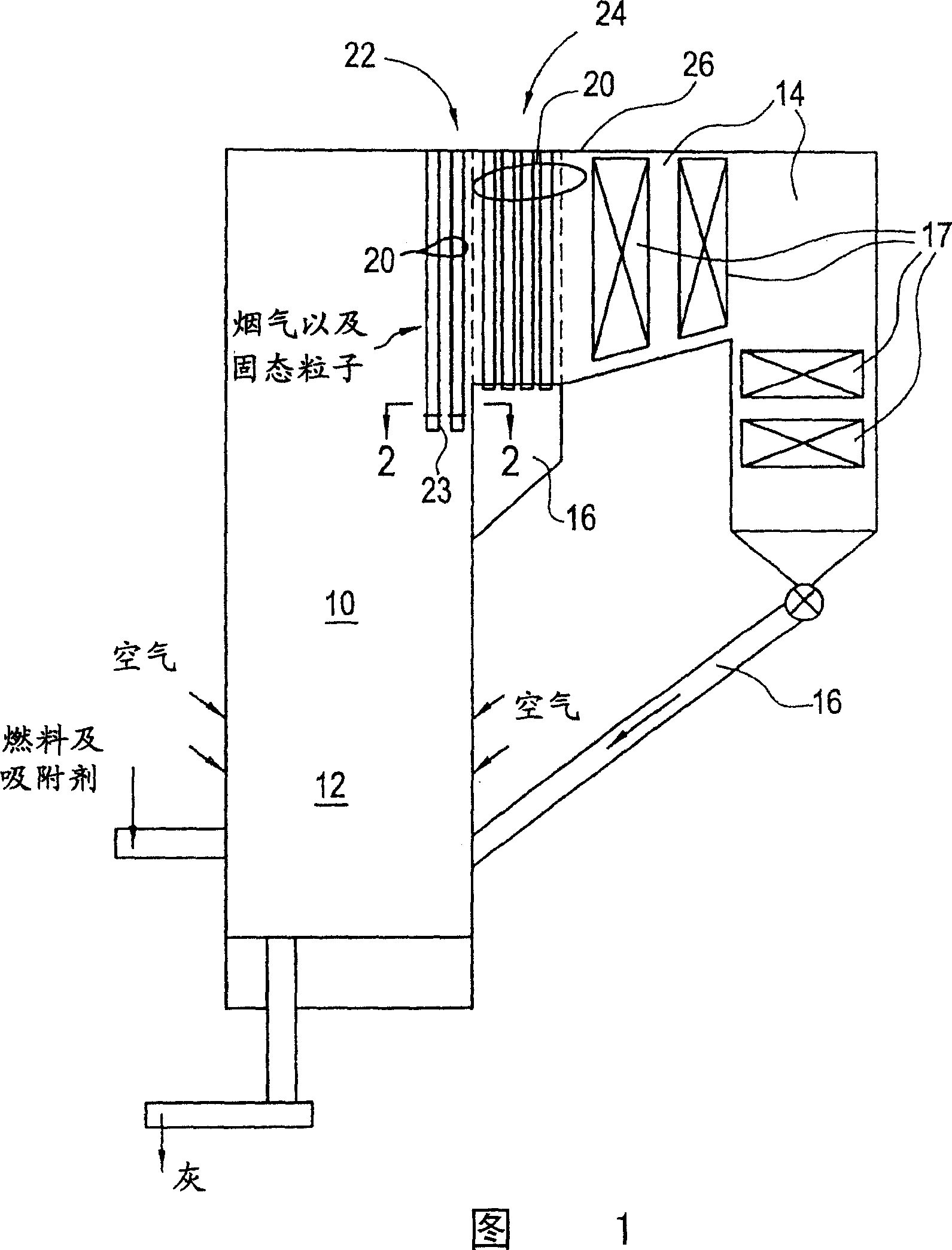

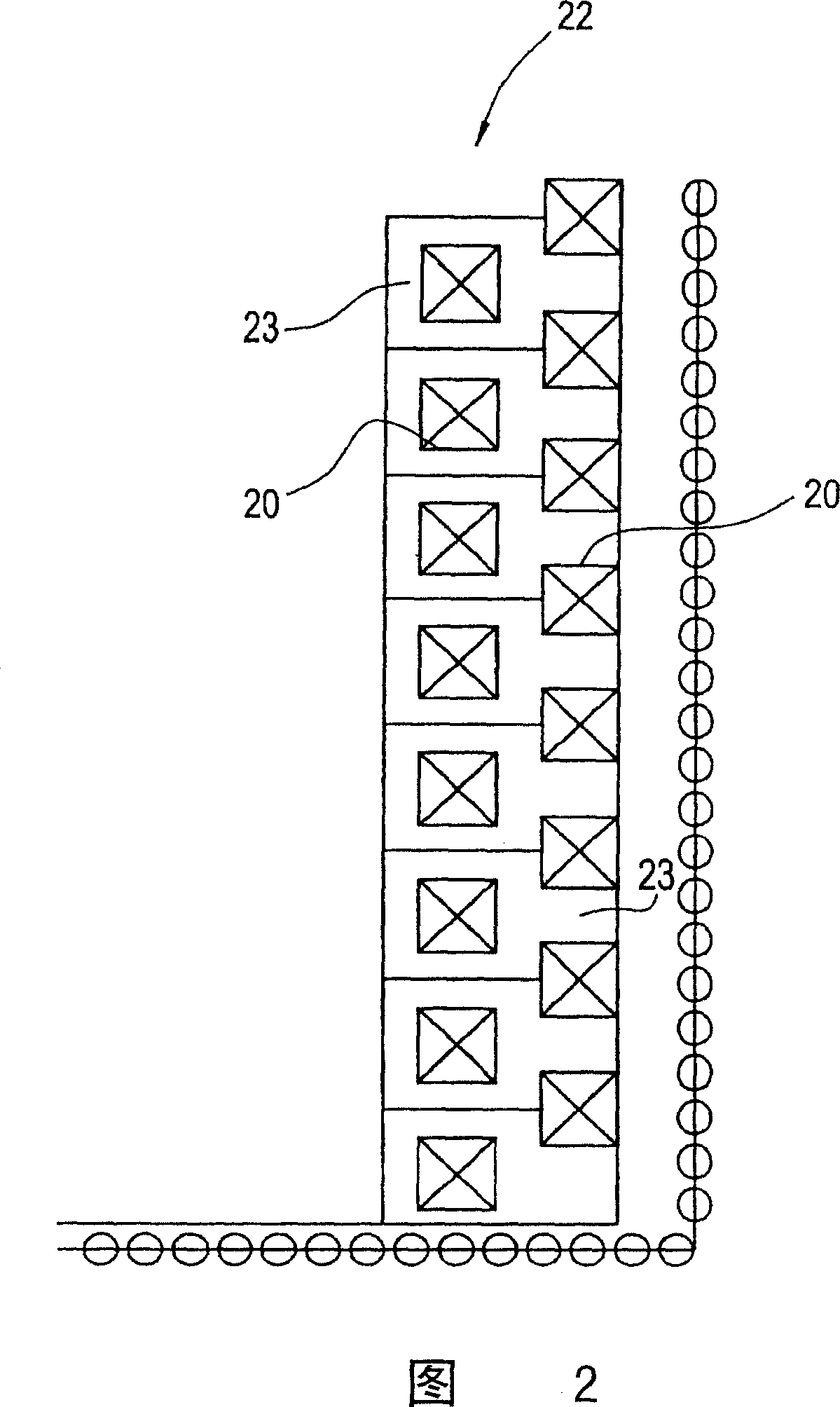

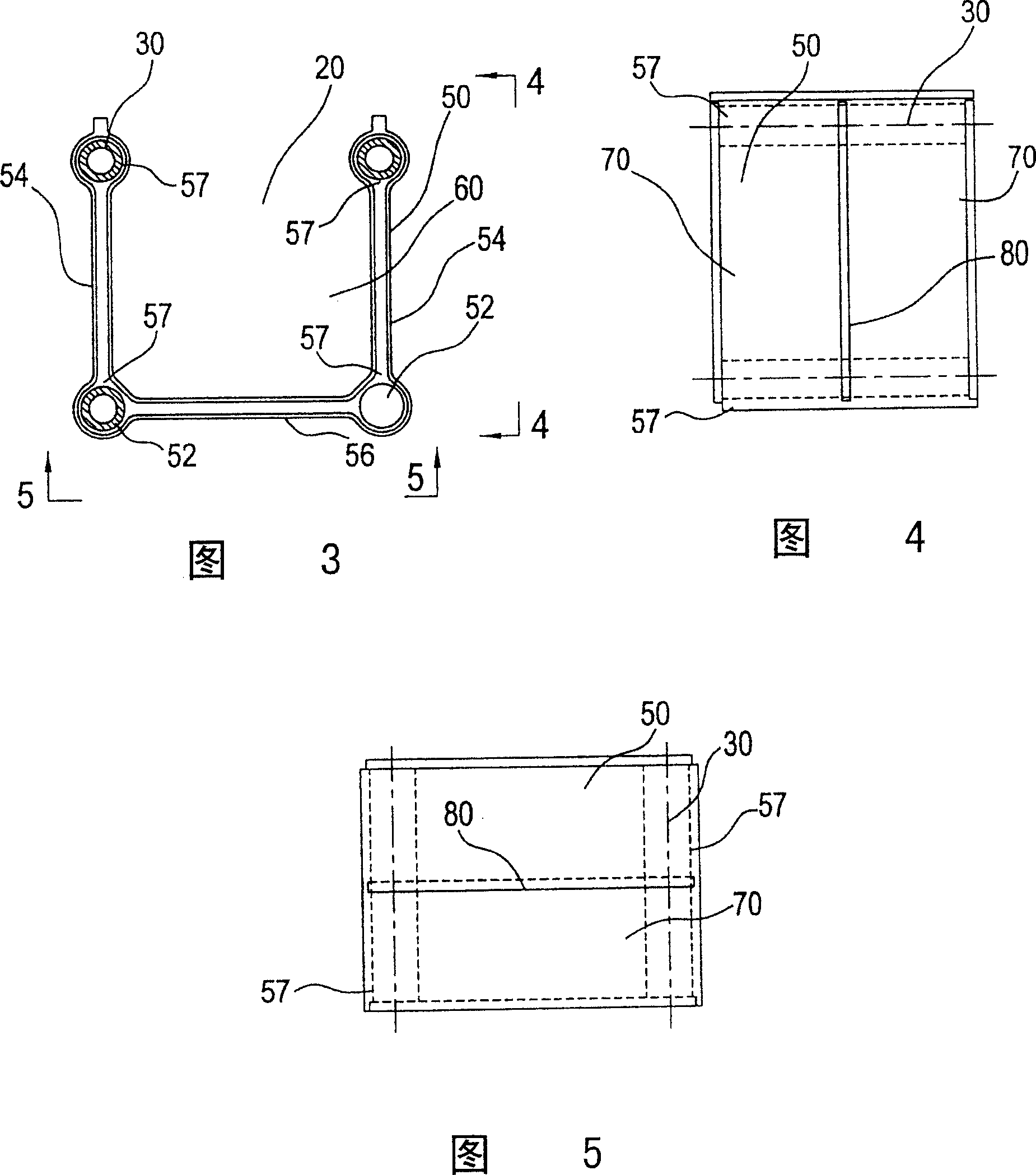

[0067] The term "CFB boiler" as used herein refers to a CFB reactor or combustion chamber in which the combustion process can take place. Although the present invention specifically refers to boilers or steam generators using a CFB combustor as the means of generating heat, it is to be understood that the present invention could readily be used in a different CFB reactor as well. For example, the present invention may be applied in reactors for chemical reactions other than those used for combustion processes, or for supplying gas / solid particle mixtures produced by combustion processes elsewhere into reactors for further A reactor for the treatment of, or for, a reactor that provides only an enclosure in which particles or solid particles are entrained in a gas that is not necessarily a by-product of the combustion process. Similarly, the term "U-beam" is used in the following discussion for ease of description and is used broadly to refer to any type of concave impact member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com