Compressor

A compressor and refrigerant gas technology, applied in the field of compressors, can solve the problems of increased compressor volume, inability to effectively reduce refrigerant gas pulsation pressure, refrigerant gas pulsation pressure limitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

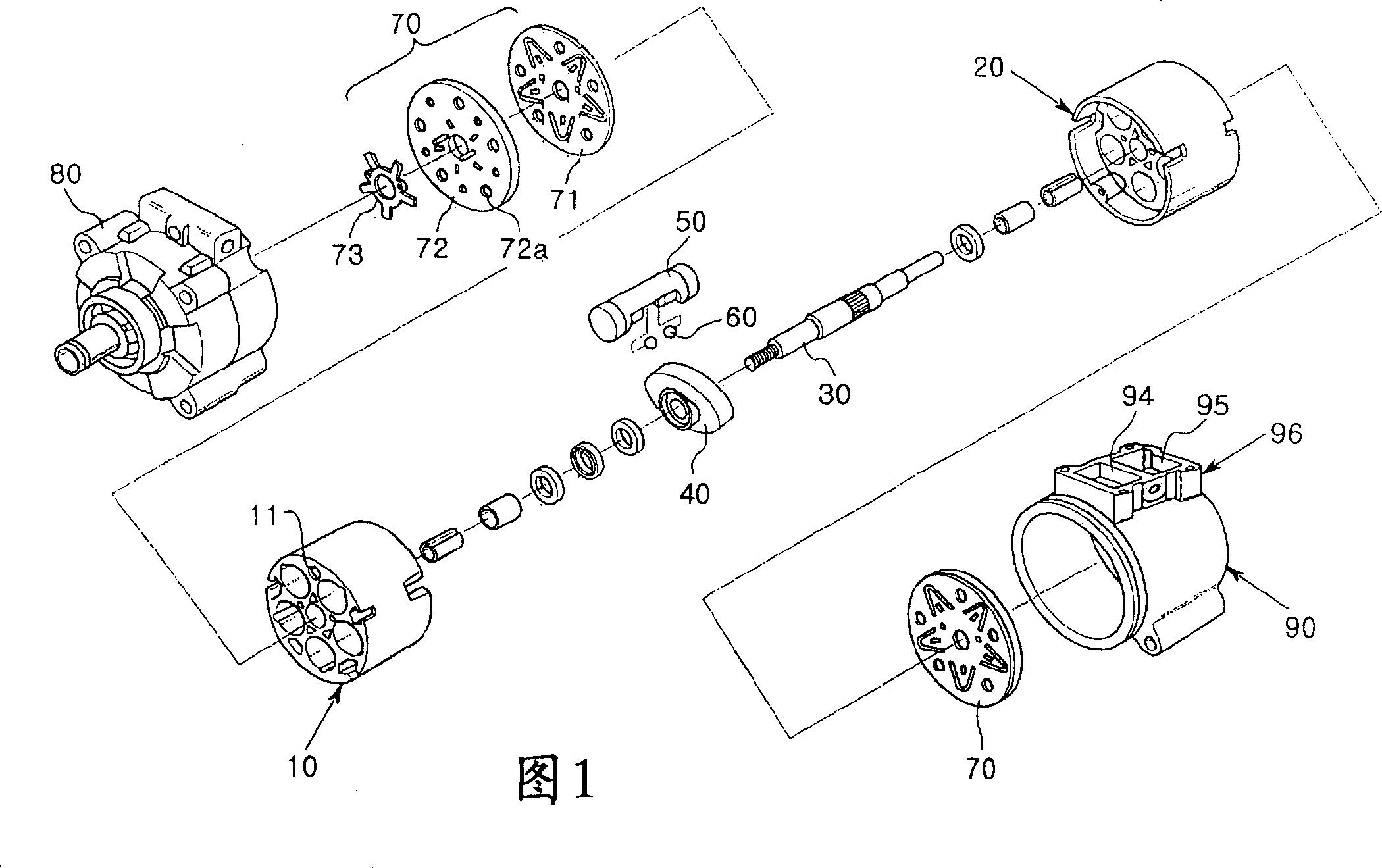

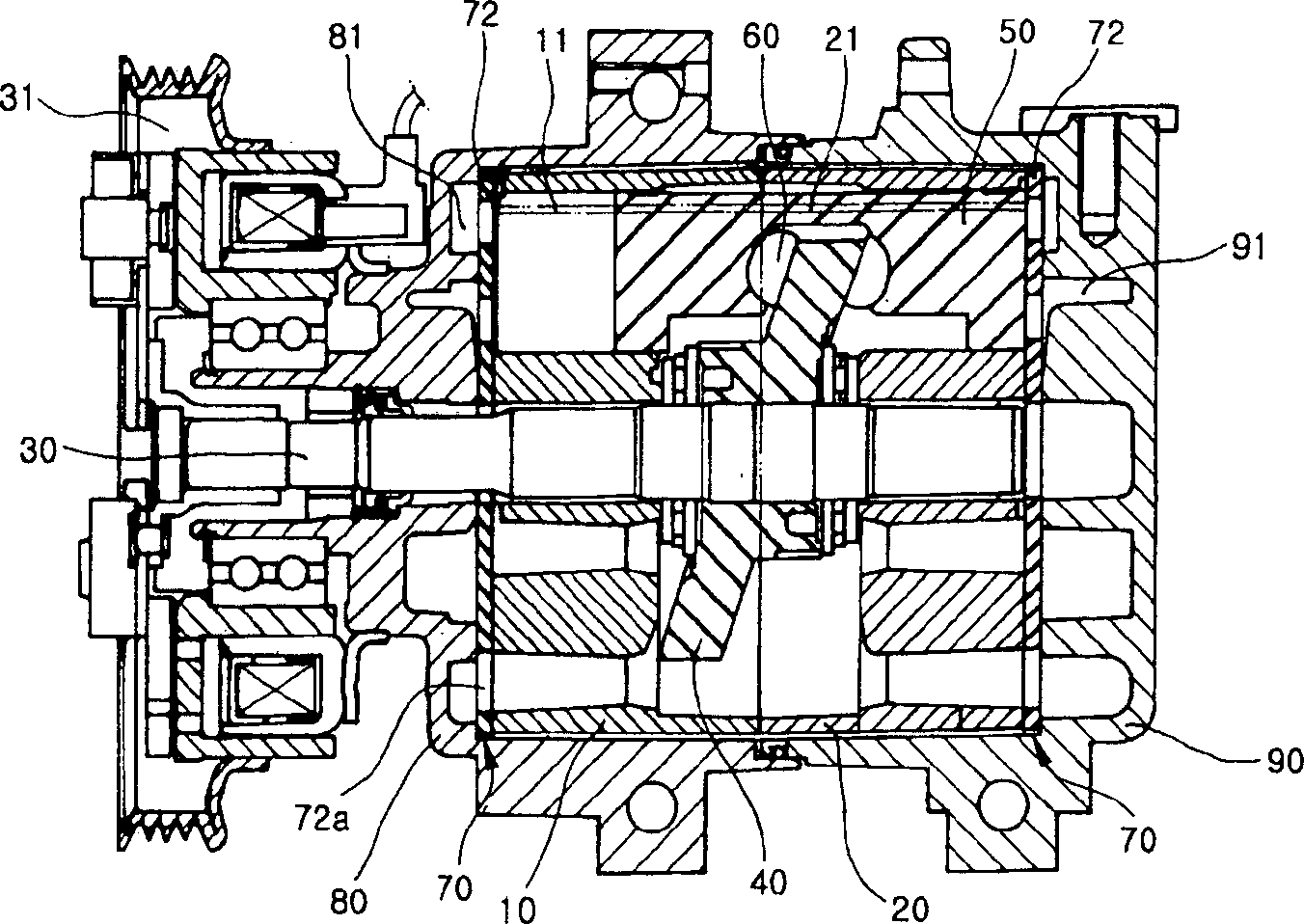

[0043] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

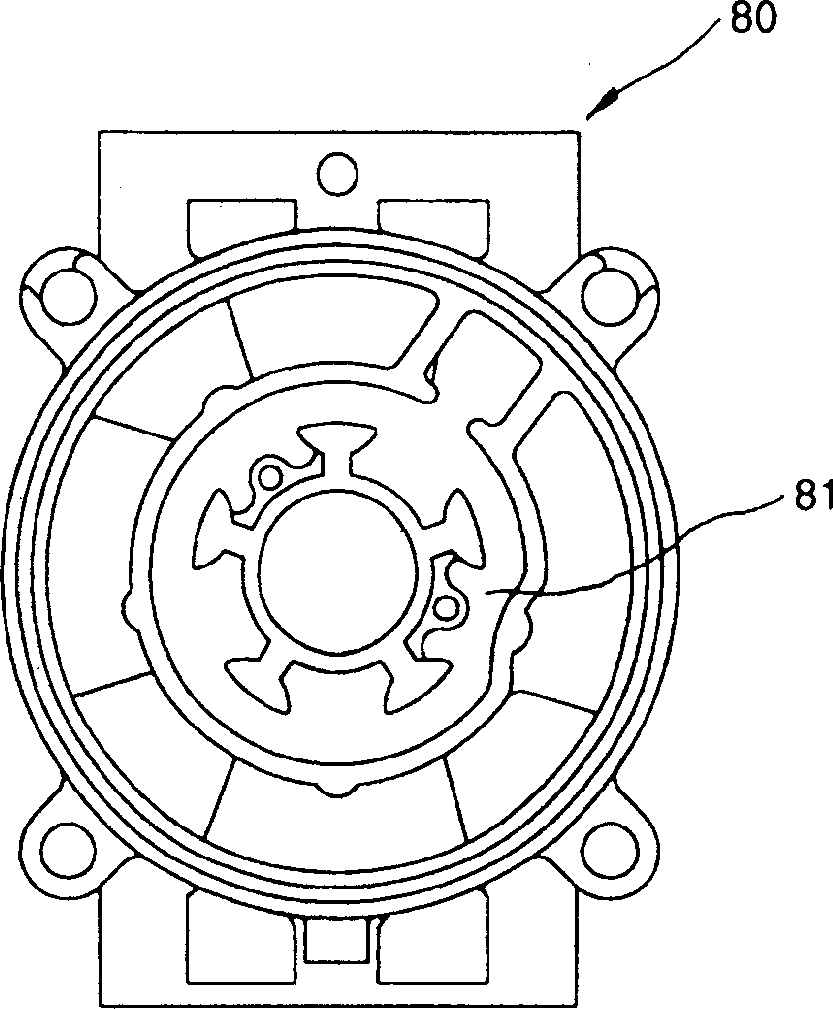

[0044] Figure 6 It is a side view of the compressor of the first embodiment of the present invention; Figure 7 for Figure 6 Side cutaway view of the compressor shown; Figure 8 for Figure 6 Front view of the front casing employed in the compressor shown; Figure 9 for Figure 6 Front view of the back casing employed in the compressor shown.

[0045] In the first embodiment of the present invention, as Figure 6 and 7 As shown, the compressor includes: a front housing 200 closing one end of the front cylinder body 400; a rear housing 300 closing one end of the rear cylinder body 500; and a front cylinder arranged to be combined with each other between the front housing 200 and the rear housing 300 Body 400 and rear cylinder block 500; drive shaft 600 rotatably supported in front cylinder block 400 and rear cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com