Process for treating ice-flower glass

A technology of frosted glass and processing technology, which is applied in the field of processing technology of frosted glass, can solve the problems of unaffordable, real frosted, poor natural visual effect, etc., and achieve the effect of simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

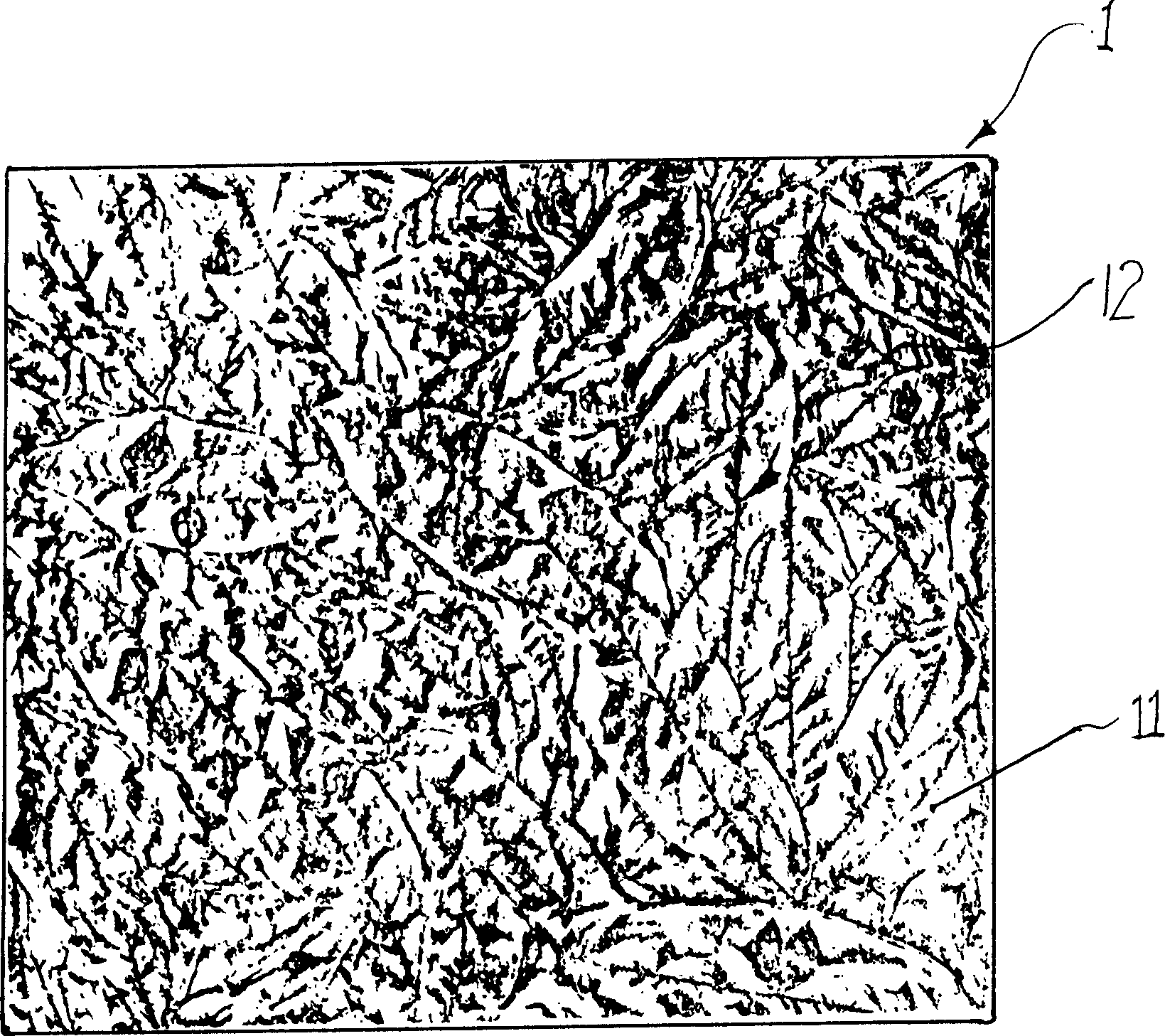

Embodiment 1

[0021] a. Select glass 11 other than tempered glass that has no cracks (patterns), no spots, good flatness and no blemishes as a glass gob;

[0022] b. Choose 120-mesh corundum and install it on the frosted disc of the frosted cutting machine, and the frosted cutting machine drives the frosted disc to rotate under the running state, so that the corundum is placed on a glass blank placed on a conveying plane below it. The surface is sanded in the state of water injection, and the speed of the glass 11 and the speed of the sanding disc are controlled at 0.85 m / min and 200 rpm respectively, so that one surface of the glass blank forms a rough surface;

[0023] c. Clean the surface of the glass blank after sanding with water to remove the sundries left by the sanding on the rough surface;

[0024] d. Put 2% bone glue, 0.5% cowhide glue and 97.5% recycled glue into a container, add hot water at about 90°C and stir evenly to form glue. The concentration of this glue is 39% as measur...

Embodiment 2

[0029] a. Select glass 11 other than tempered glass that has no cracks (patterns), no spots, good flatness and no blemishes as a glass gob;

[0030] b. Choose 130-mesh corundum and install it on the frosted disc of the frosted cutting machine, and the frosted cutting machine drives the frosted disc to rotate under the running state, so that the corundum is placed on a conveying plane below it. One of the glass blanks The surface is sanded in the state of water injection, and the speed of the glass and the speed of the sanding disc are controlled at 0.9 m / min and 220 rpm respectively, so that one surface of the glass blank forms a rough surface;

[0031] c. Clean the surface of the glass blank after sanding with water to remove the sundries left by the sanding on the rough surface;

[0032] d. Put 3% bone glue, 0.5% cowhide glue and 96.5% recycled glue into a container, add hot water at about 90°C and stir evenly to form glue. The concentration of this glue is 39% as measured b...

Embodiment 3

[0037] a. Select glass 11 other than tempered glass that has no cracks (patterns), no spots, good flatness and no blemishes as a glass gob;

[0038] b. Select 140-mesh corundum and install it on the frosted disc of the frosted cutting machine, and the frosted cutting machine drives the frosted disc to rotate under the running state, so that the corundum is placed on a conveying plane below it. One of the glass blanks The surface is sanded in the state of water injection, and the speed of the glass and the speed of the sanding disc are controlled at 1.0 m / min and 250 rpm respectively, so that one surface of the glass blank forms a rough surface;

[0039] c. Clean the surface of the glass blank after sanding with water to remove the sundries left by the sanding on the rough surface;

[0040] d. Put 4% bone glue, 0.5% kraft glue and 95.5% recycled glue into a container, add hot water at about 90°C and stir evenly to form glue. The concentration of this glue is 39% as measured by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com