Method for manufacturing magnetic control overtravel-limit switch

A travel switch, switch box technology, applied in magnetic/electric field switches, electrical switches, electrical components, etc., can solve problems such as easy failure, and achieve the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

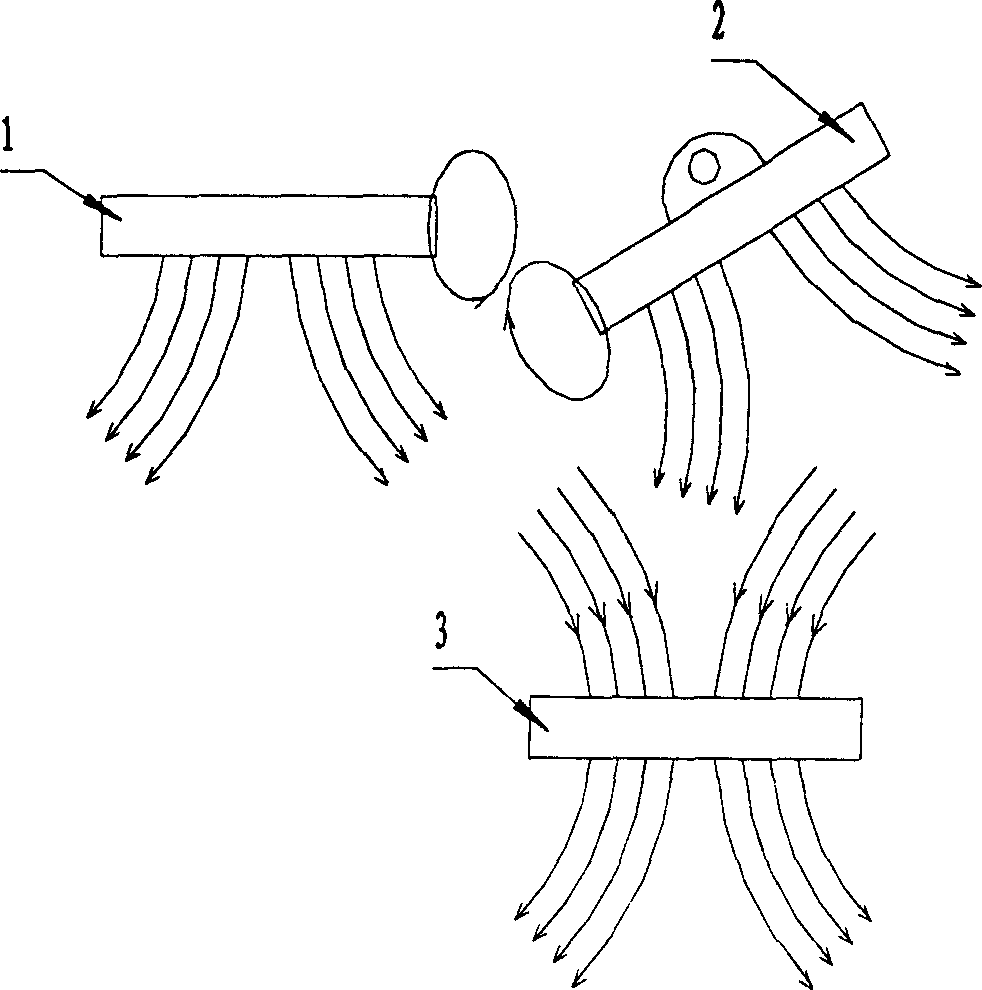

[0010] figure 1 In the figure, the arc with the arrow represents the magnetic force line, and the direction of the arrow is the direction of the magnetic force line. The fixed magnet (1) is fixed, and the rotatable magnet (2) can rotate around the rotating shaft. The direction of the magnetic force line is consistent with that of the fixed magnet (1). The directions of the magnetic force lines adjacent to the fixed magnet (1) and the rotating magnet (2) are also the same, so that the adjacent parts of the two magnets are always in a state of repulsion, as shown in the figure, the rotating magnet (2) is pushed by the repulsive force to reverse The hour hand turns. The execution magnet (3) is consistent with the direction of the magnetic force lines of the fixed magnet and the rotating magnet, the magnetic field strength is two to three times greater than that of the fixed magnet (1) and the rotating magnet (2), and it moves parallel to the fixed magnet, as shown in the figure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com