Power changing device

A power conversion device and power converter technology are applied in the output power conversion device, DC power input is converted into DC power output, and irreversible DC power input is converted into AC power output, etc. Problems such as increased switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

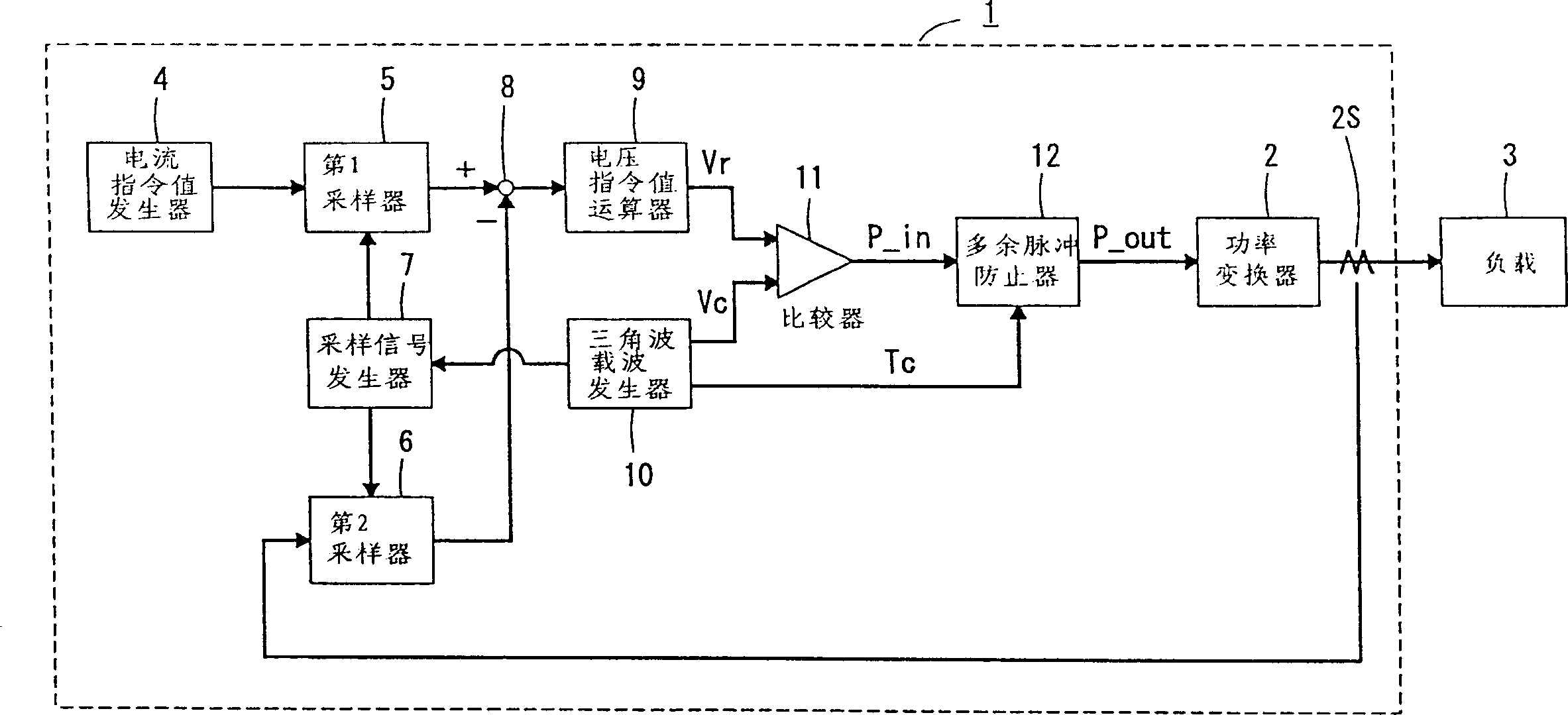

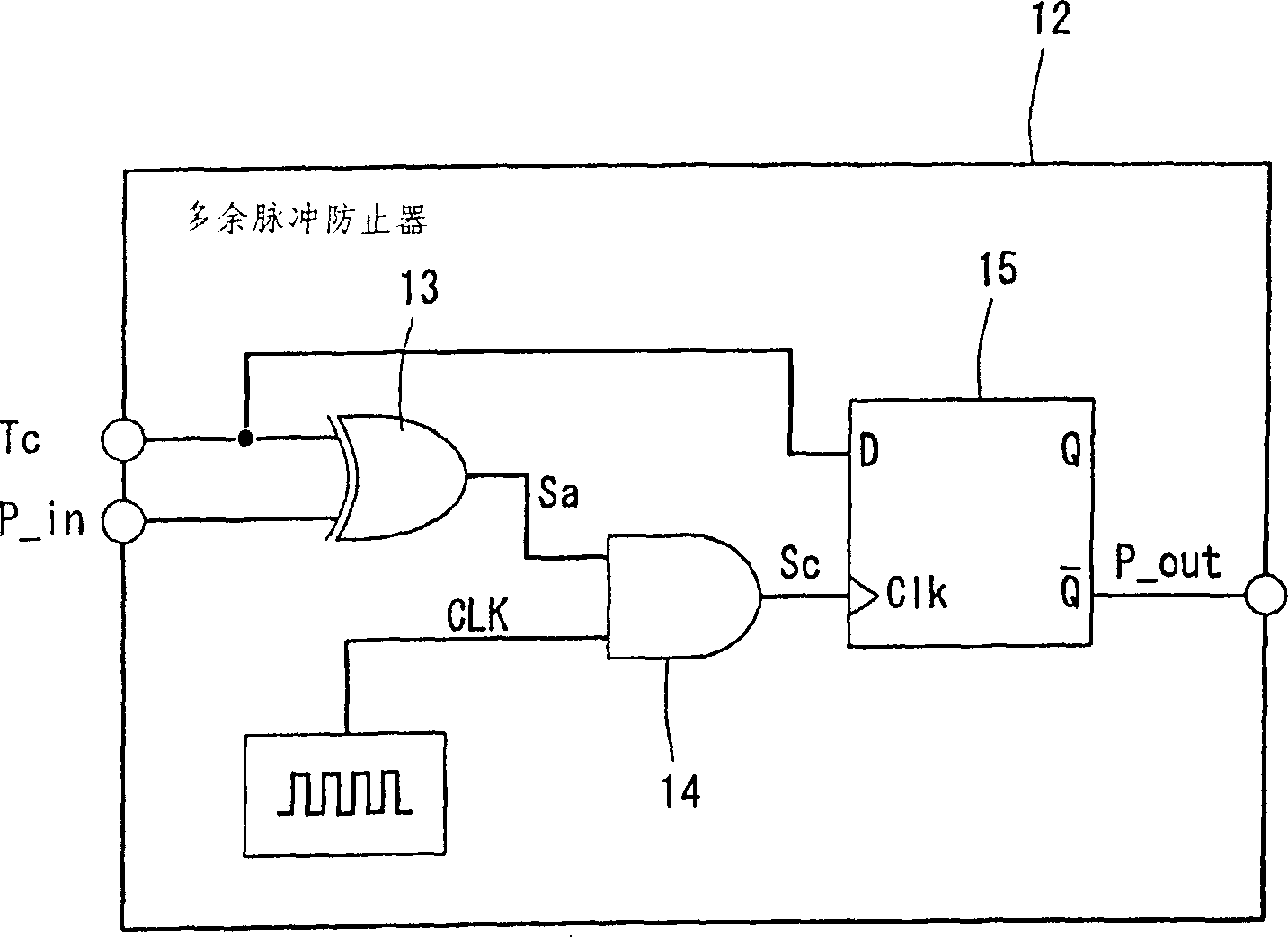

[0046] The following is based on figure 1 The shown block diagram illustrates a power conversion device according to an embodiment of the present invention.

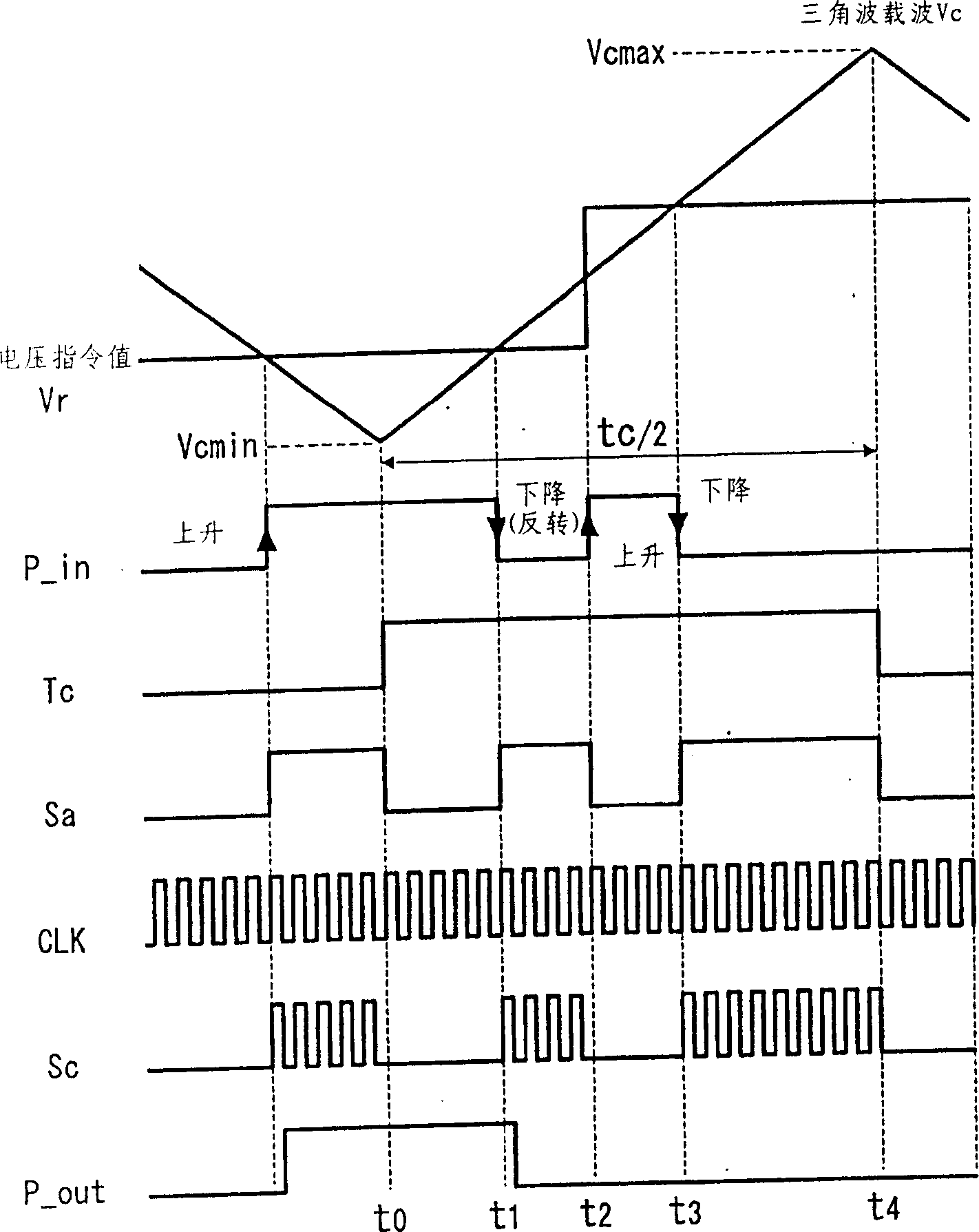

[0047] exist figure 1 Among them, the power conversion device 1 includes a power converter (power conversion device) 2 having a power switching element such as a transistor, and a current command value generator 4 serving as a current command value generator for generating a current command value of the power converter 2, which converts power The first sampler (first sampling device) 5 that samples the first current command value of the converter 2 and simultaneously outputs the second current command value detects the first current of the current detector 2s that detects the current flowing through the load 3 The second sampler (second sampling device) 6 that samples the value and outputs the second current detection value at the same time determines the sampling time of the first and second samplers 5 and 6, and sim...

Embodiment 2

[0059] The following is based on Figure 4 The block diagram of the power conversion apparatus shown illustrates other embodiments of the present invention. exist Figure 4 in, with figure 1 The same reference numerals denote the same or corresponding parts, and explanations thereof are omitted.

[0060] exist Figure 4 Among them, the second unnecessary pulse preventer 20 has an intersection detection device that detects the intersection of the first voltage command value generated from the voltage command value computing device 9 and the triangular wave carrier. A voltage command value suppressing device for generating a second voltage command value that suppresses changes in the first voltage command value without intersecting the triangular wave carrier again, and comparing the second voltage command value with the triangular wave carrier to generate the first PWM signal, and using the second voltage command value at the same time The 1PWM signal drives the comparator...

Embodiment 3

[0084] The following is based on the block diagrams of power conversion devices representing other embodiments Figure 9 Explain this description. exist Figure 9 in, with figure 1 The same reference numerals indicate the same or corresponding parts.

[0085] In Embodiment 1, since the first PWM signal is obtained by comparing the voltage command value Vr with the triangular wave carrier Vc, and the power converter 2 is driven by the second PWM signal that suppresses the inversion of the first PWM signal, the second PWM signal suppresses the first PWM signal. The redundant pulse portion of the 1PWM signal is removed from the command of the voltage command value Vr.

[0086] In this embodiment, while suppressing unnecessary pulses, the power converter is operated faithfully according to the voltage command value Vr.

[0087] exist Figure 7 and Figure 8 Among them, the voltage error compensator 21 obtains the three-pulse width difference ΔP(t) between the first PWM sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com