High-temperature air duct denitration reactor and method therewith for denitration

A denitrification reactor and air duct technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of blocking downstream equipment, loss of catalytic effect, high cost of ammonia production, etc., to achieve convenient installation, high efficiency and low cost The effect of cost removal and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

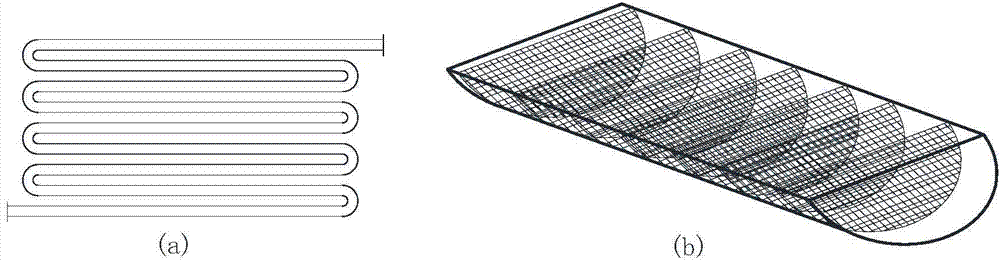

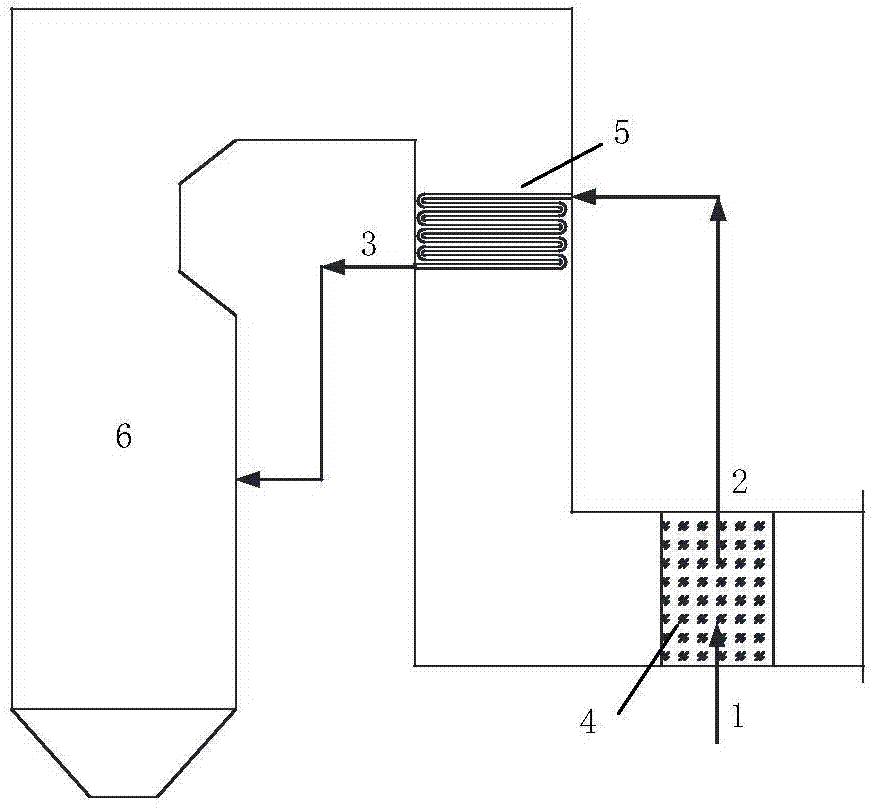

[0021] A high-temperature air duct denitrification reactor, which is arranged in the boiler flue communicated with the furnace 6, the high-temperature air duct denitrification reactor is a serpentine metal tubular air duct loaded with barbed wire inside, and its inlet is separated from the NOx of the flue gas The device 4 communicates, and the outlet communicates with the furnace 6 .

[0022] The snake-shaped metal tubular air duct is loaded with multi-layer barbed wire, and micro-fins are also added to enhance heat transfer. The regional temperature is around 600°C to 800°C, which can ensure that the reducing agent and NO are catalyzed by the iron wire. X The reaction proceeds. The inlet of the high-temperature air duct denitrification reactor 5 is CO+NOx gas 2, and its source is the NOx separation device 4 of the downstream flue gas. The NOx...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com