Phase transformation heat storing electrothermal exchanger and intelligent controlling circulating running system

A phase-change heat storage, intelligent control technology, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of low heat storage density, short time, corrosion of containers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

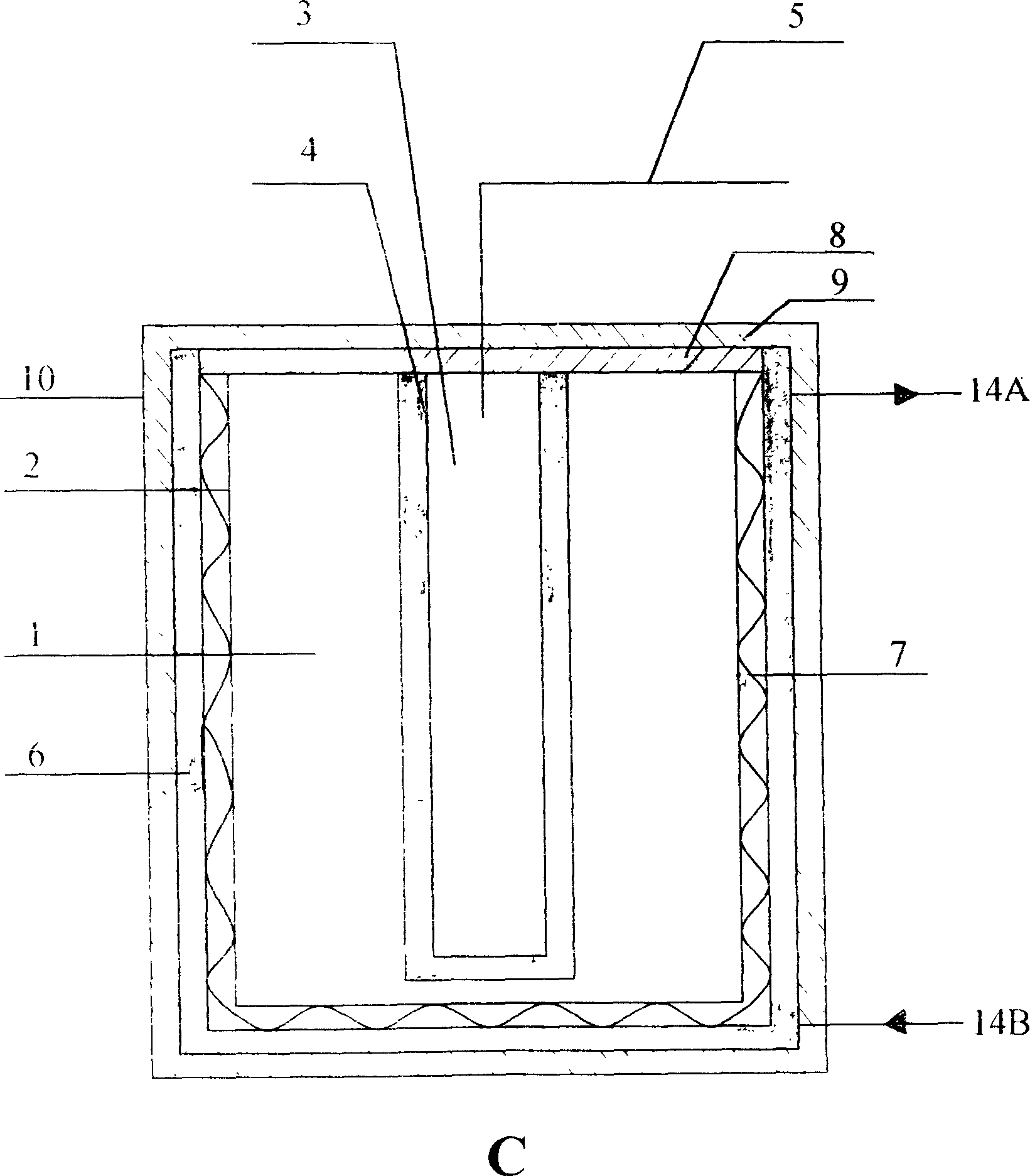

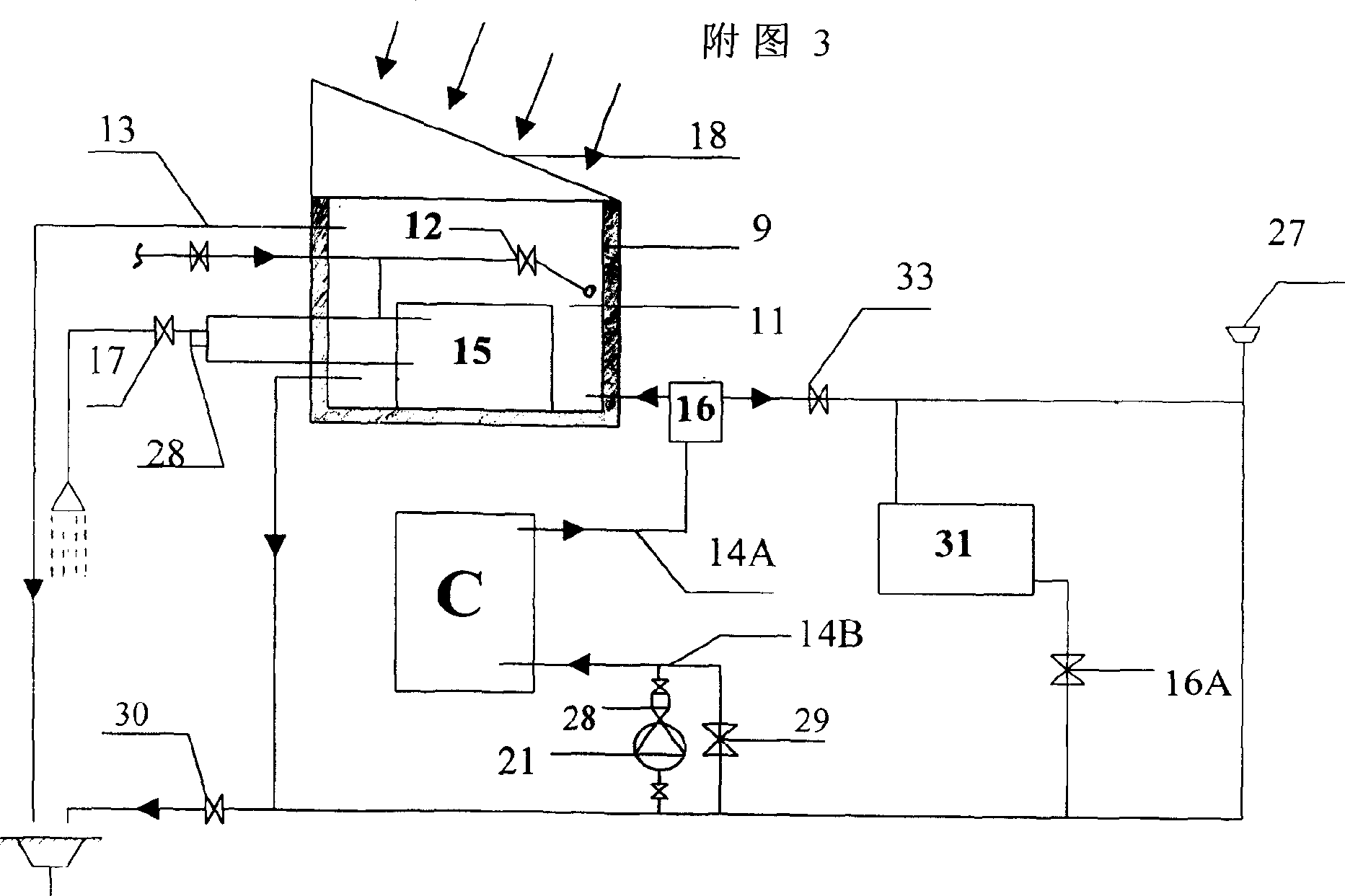

[0030] A specific example is: adopt a high temperature resistant stainless steel plate with a thickness of 1.2 millimeters, weld two square heat storage boxes (2) with a height of 500 millimeters, a width of 300 millimetres, and a thickness of 110 millimeters, leave an M14 threaded hole on the top, and leave 18mm on the four sides. A hole with a diameter of 5 mm is filled with 70%-85% of the effective volume of the heat storage box (2) into the heat storage material (1), i.e. commercially available 58# refined paraffin wax, and after the remainder of the effective volume is evacuated, use The M14 screw seals the M14 threaded hole.

[0031] Put the electric heating assembly (3), that is, the electric heating plate with a total rated power of 2400W, a length of 450 mm, and a width of 280 mm. After placing an insulating mica board (4) of the same size on both sides, clamp it with two heat storage boxes (2). Hold it, and use M4 screws to fix it through 18 holes with a diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com