Device for preventing reverse rotationof scroll compressor

A scroll compressor, reverse rotation technology, applied in the field of scroll compressors, can solve the problems of reduced efficiency, energy loss, and noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

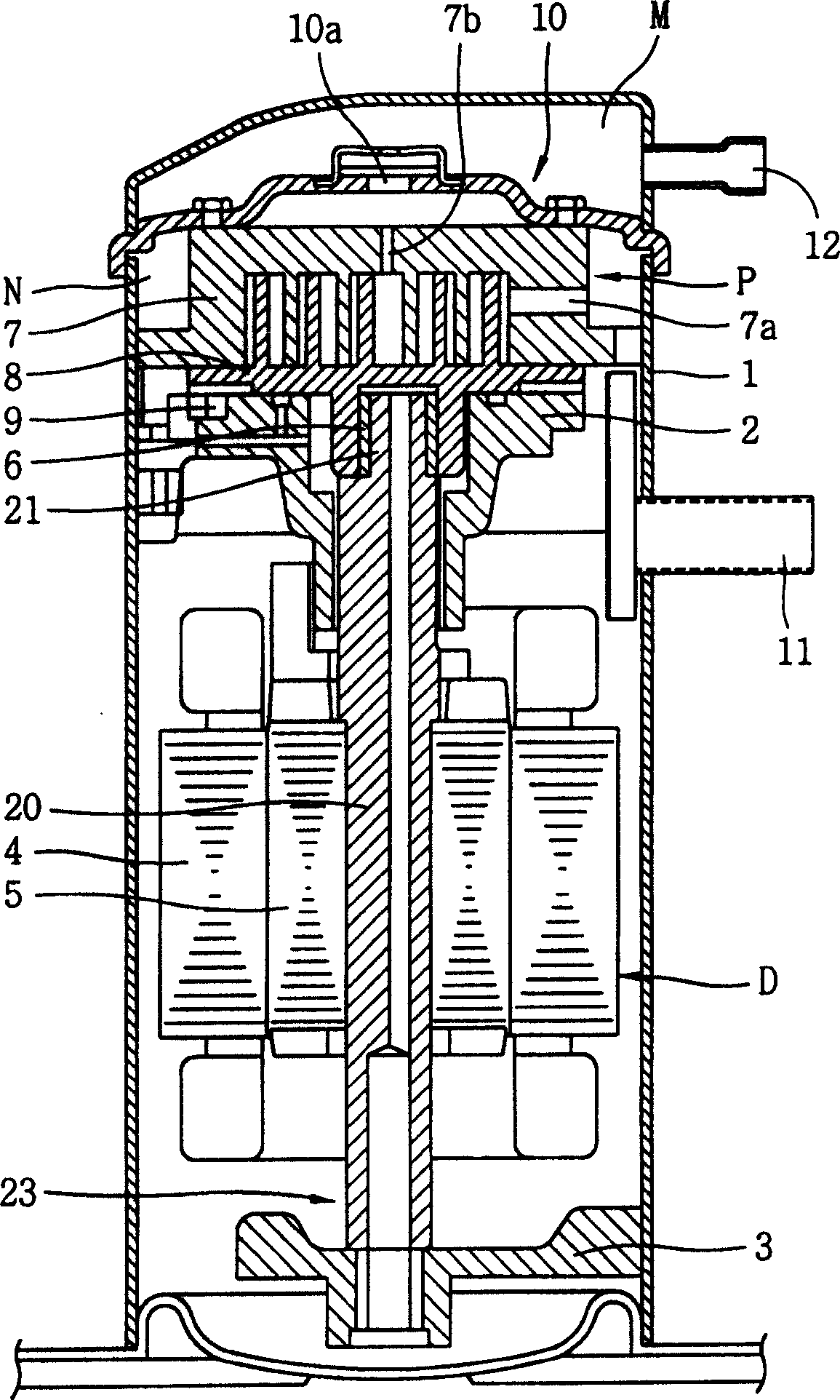

[0029] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are shown in the accompanying drawings.

[0030] Hereinafter, an apparatus for preventing reverse rotation of a scroll compressor according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

[0031] In the drawings, the same reference numerals will be used for the same structures as those in the prior art, and the description will not be repeated.

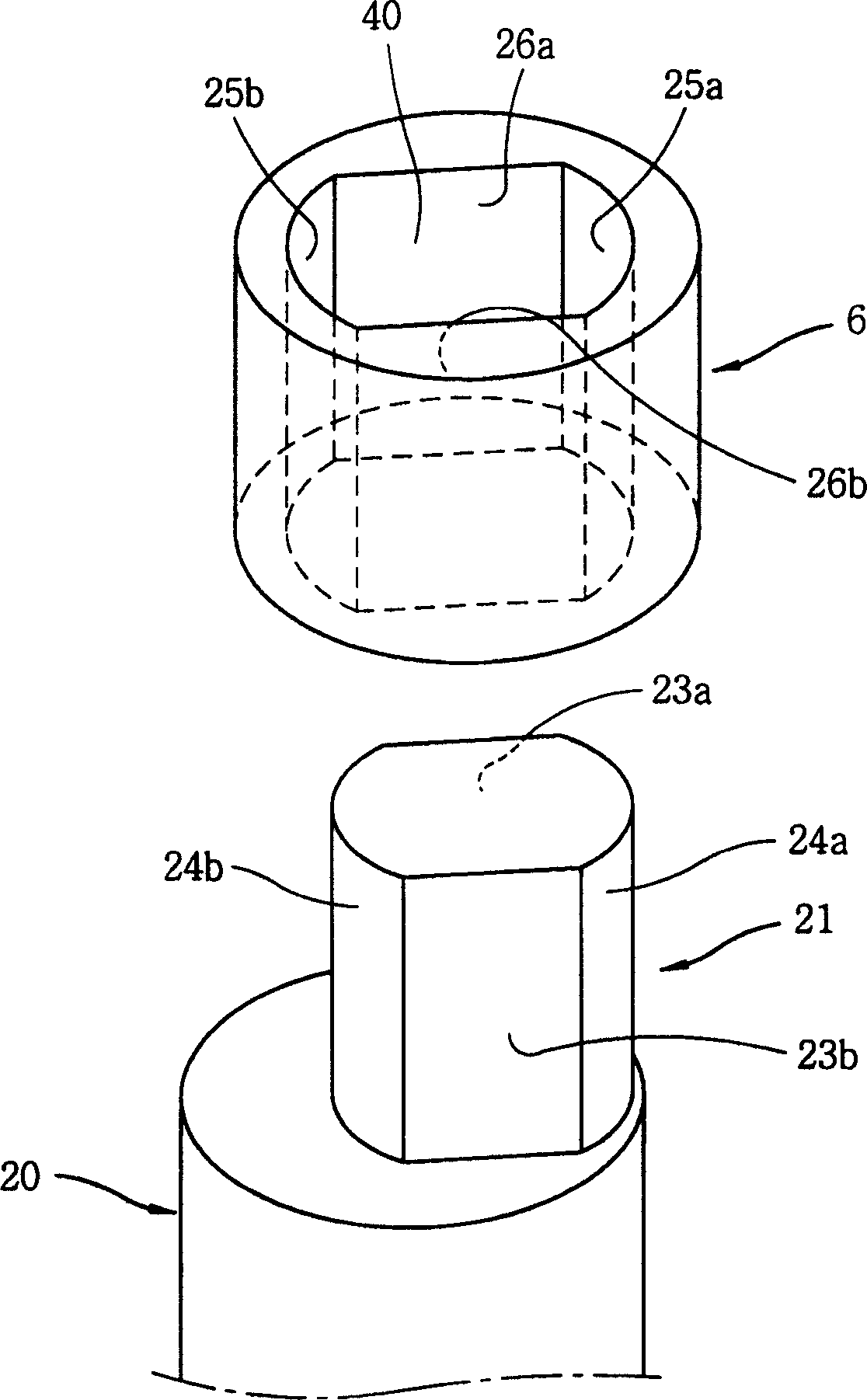

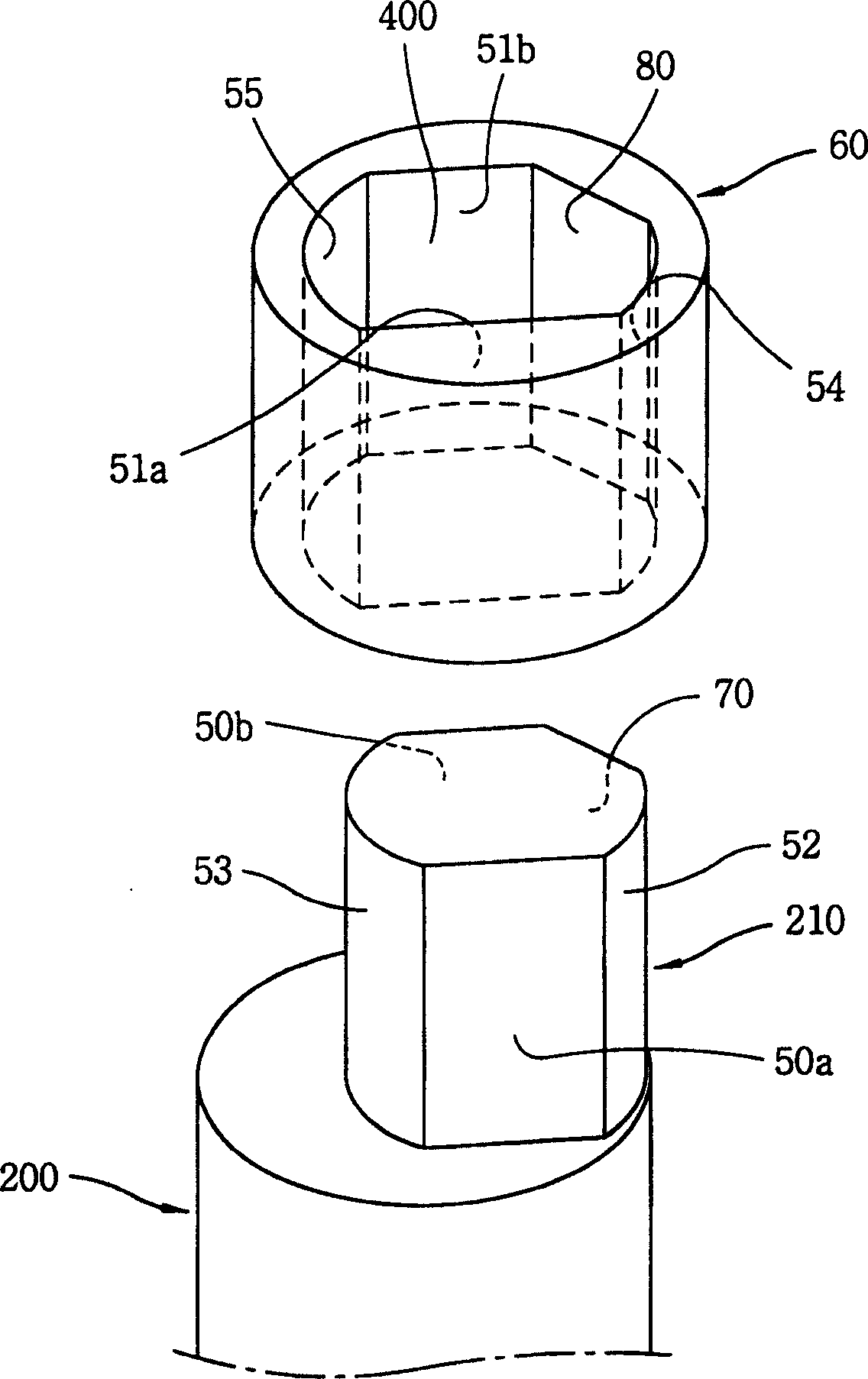

[0032] image 3 An exploded perspective view showing the eccentric portion of the shaft and the sliding sleeve. Figure 4 Yes image 3 , showing the eccentric portion and the sliding sleeve of the forward rotating shaft according to the present invention. Figure 5 Yes image 3 , showing the eccentric portion and the sliding sleeve of the counter-rotating shaft according to the present invention.

[0033] like image 3 As shown, a device for preventing re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com