Automatic liquid operation control system

A technology for manipulating systems and liquids, used in analytical materials, instruments, etc., to solve problems such as undetected dispensing tip removal, tip destruction, system damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

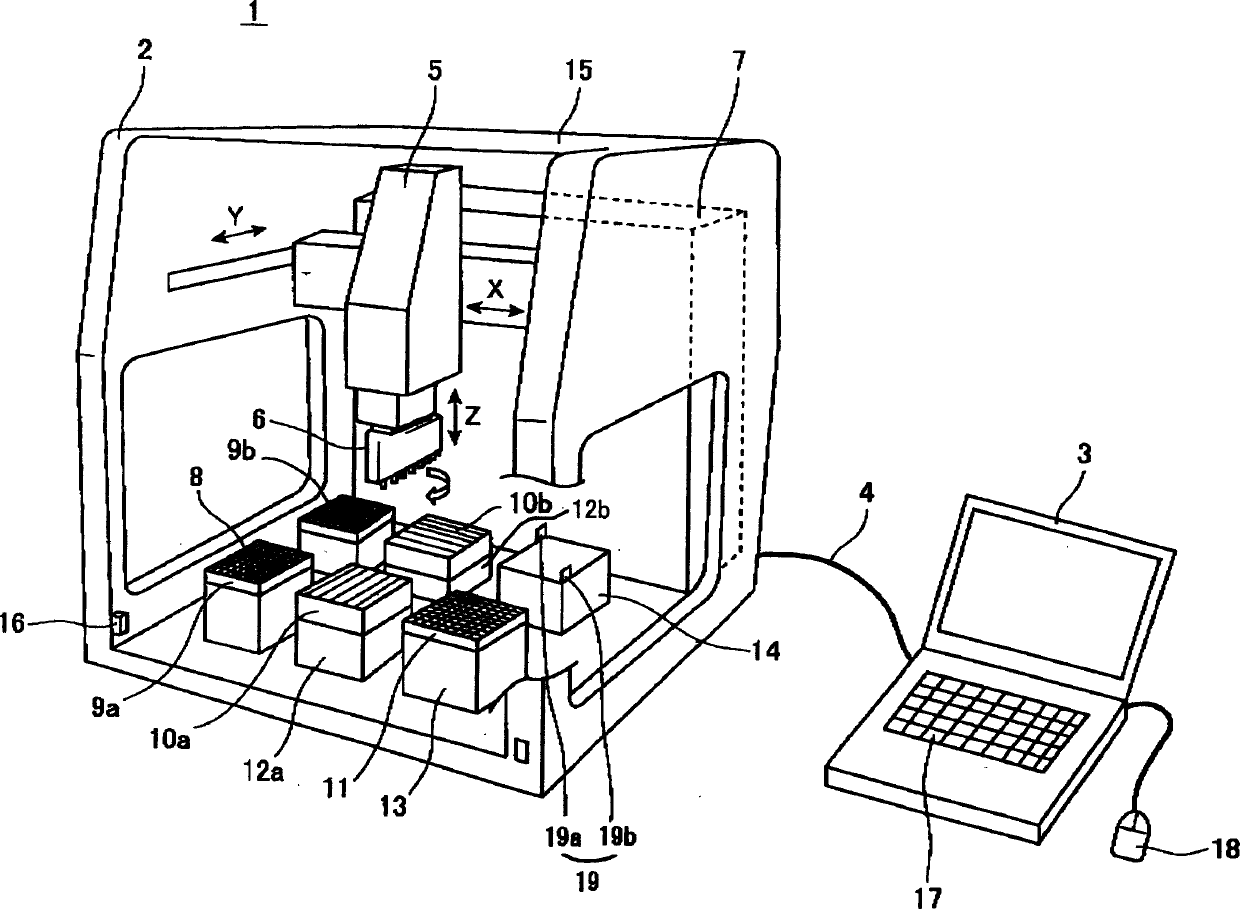

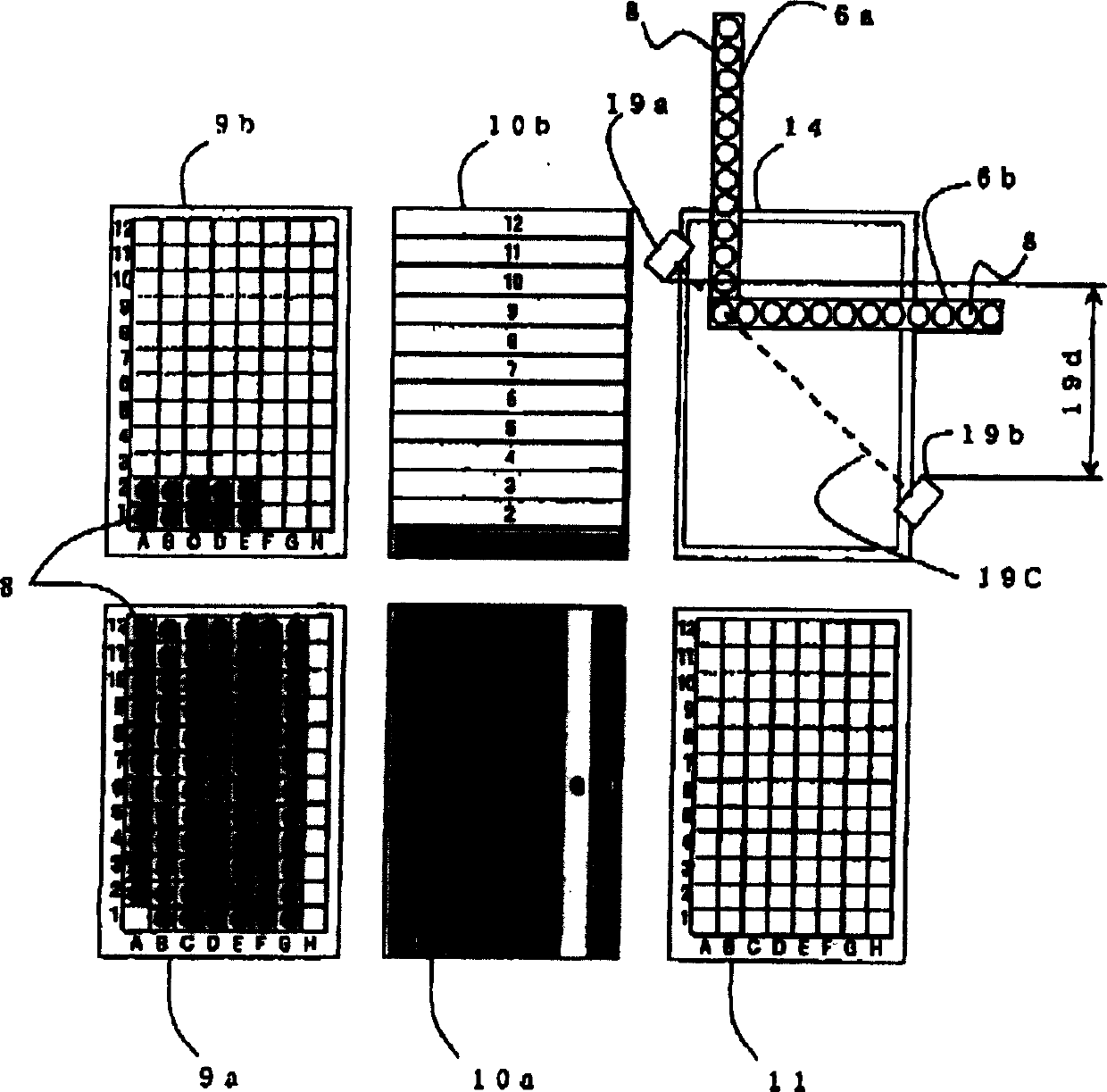

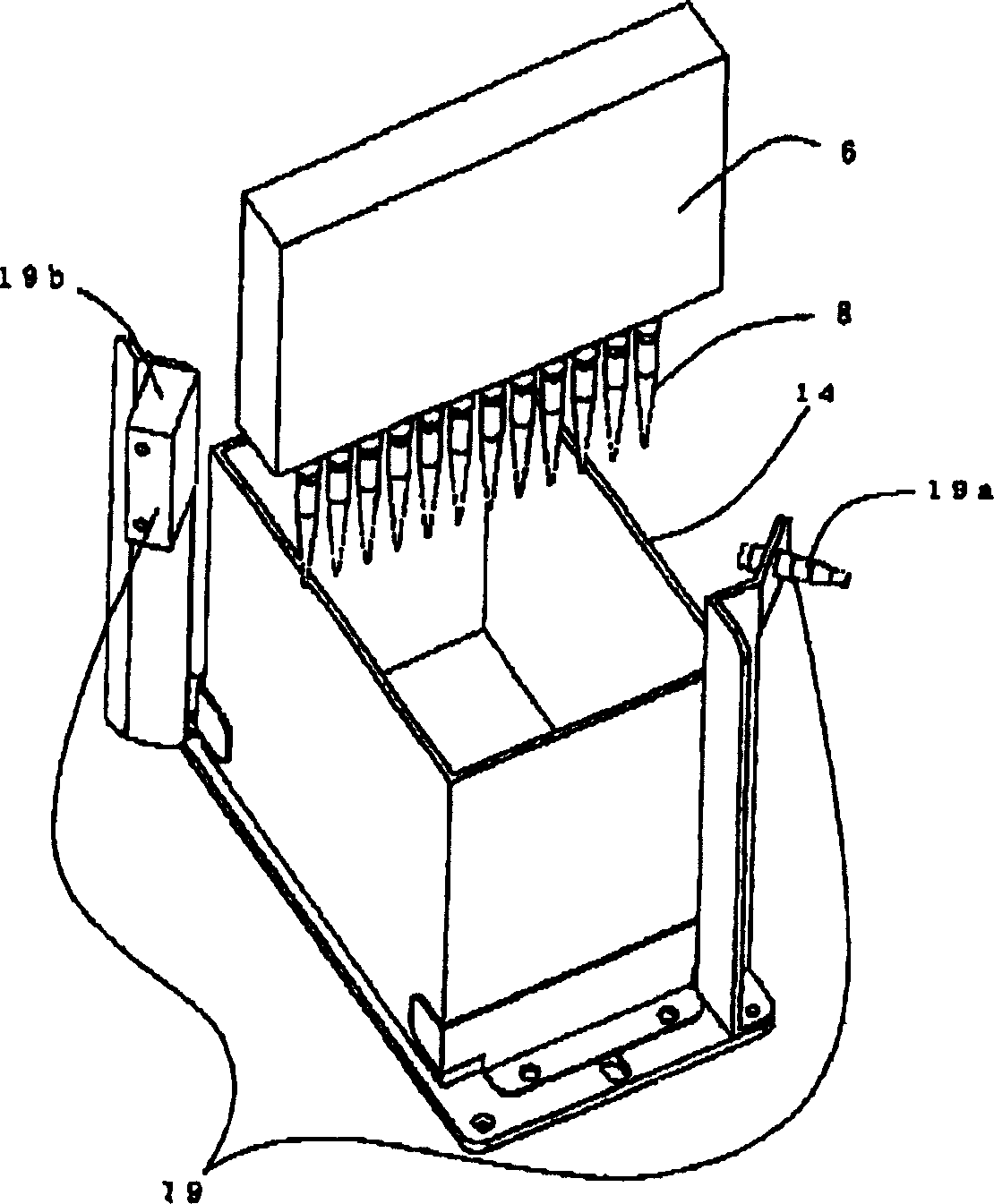

[0022] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Fig. 1 shows an automatic liquid handling system 1 according to a preferred embodiment of the present invention. Figure 2 shows the arrangement of each container contained in the main body 2 of the automatic liquid handling system 1 seen from above. The automatic liquid handling system 1 includes a main body 2 and a control device 3 connected together by a communication cable 4 such as a LAN (Local Area Network) cable. A general-purpose personal computer is used as the control device 3 . The main body 2 of the automatic liquid handling system 1 includes: a robot 5 capable of moving and stopping in 3D space; a dispensing head 6 arranged at the end of the robot 5; and a drive circuit 7 for driving according to conditions input into the control device 3 Subject 2.

[0023] The robot has three orthogonal axes X, Y and Z, and can be moved to predetermine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com