Heat storage type thawing device

A heat storage and snow melting technology, which is applied in the field of devices for melting roofs and road snow, and can solve problems such as subsidence of foundations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

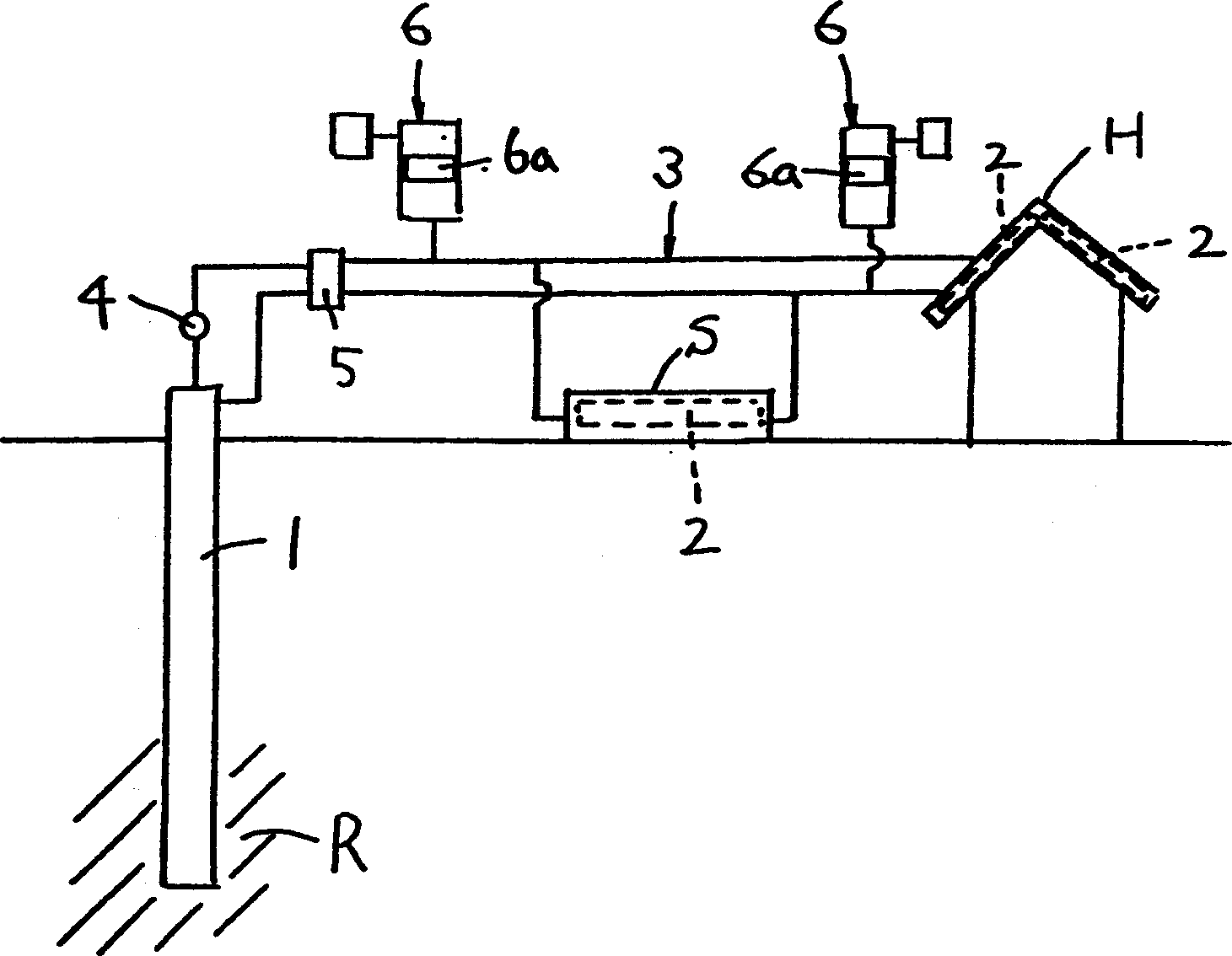

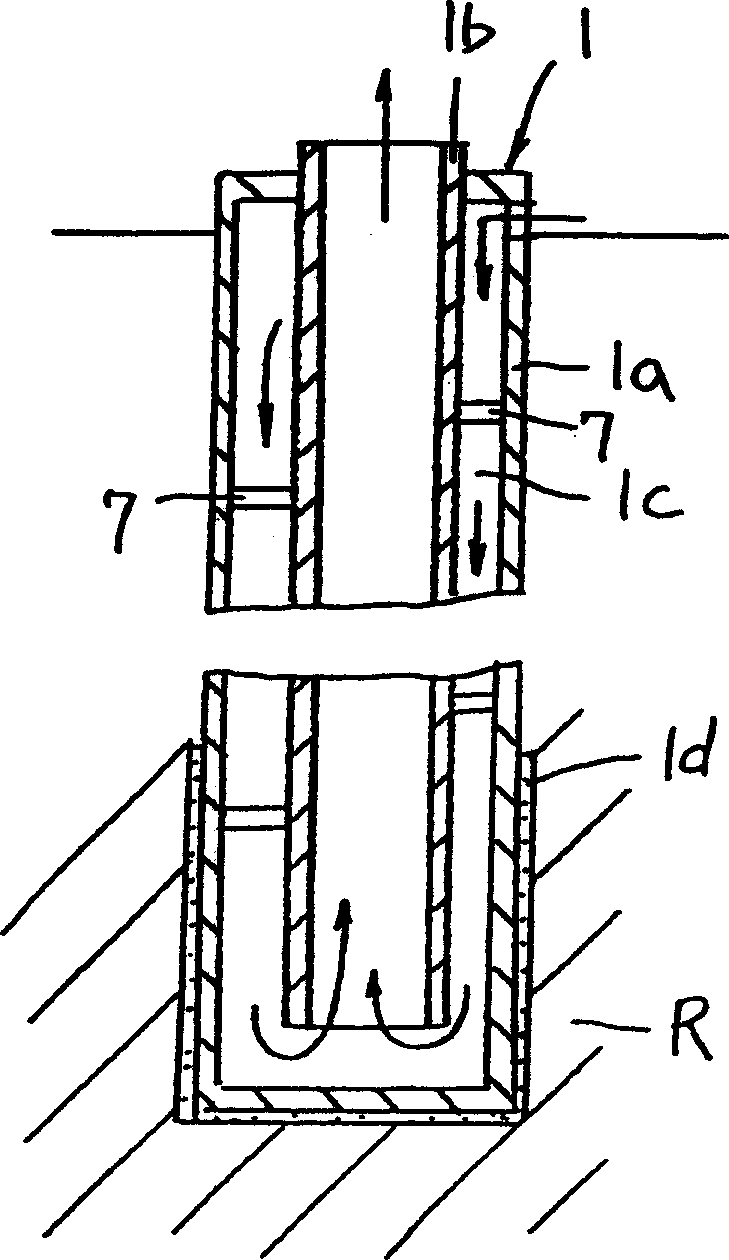

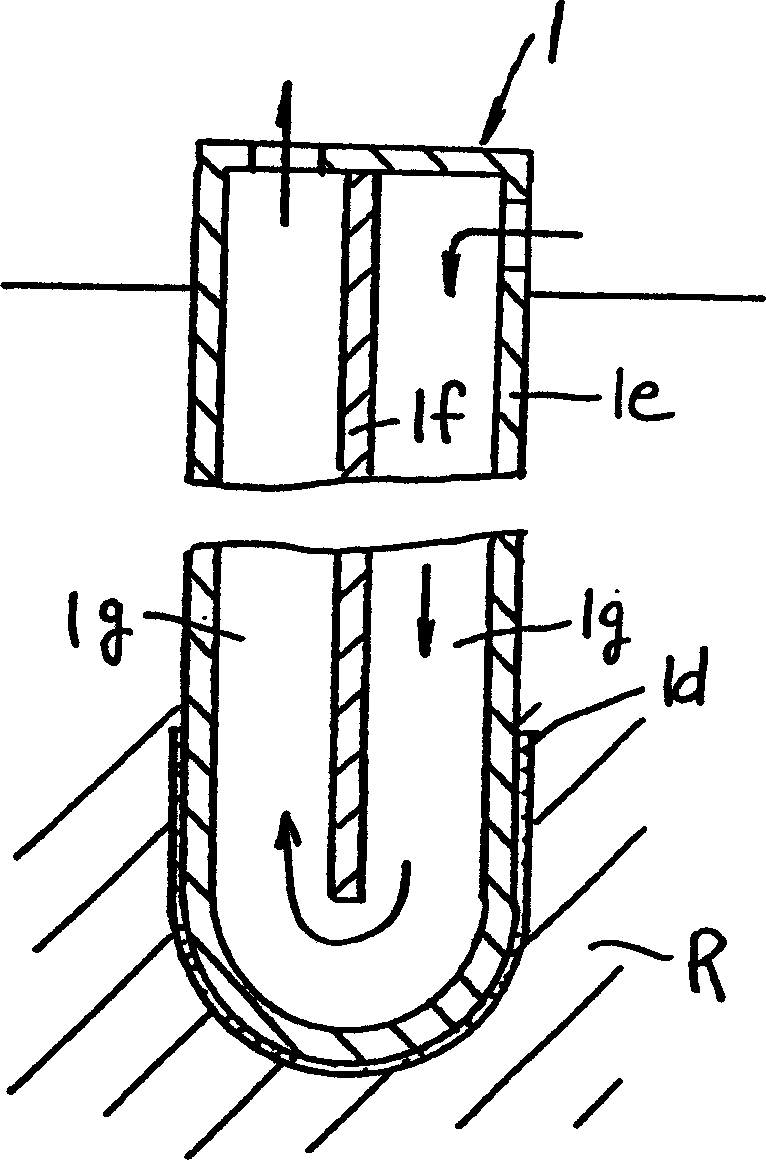

[0036] Embodiments of the thermal storage type snow melting device related to the present invention, such as Figure 1 to Figure 3 shown. In this device, the heat exchanger 1 , which circulates antifreeze inside and can exchange heat with the rock bed R, is buried vertically to the rock bed R as deep as 100m-200m. The snow-melting tray 2 is set in a place where the sun's rays can irradiate in summer, and the heat exchanger 1 and the snow-melting tray 2 are connected by a circulation pipe 3 provided with a pump 4, a switching valve 5 and an accumulator 6.

[0037] Then in summer, the solar energy is taken by the snow melting tray 2, and the solar energy is stored in the rock bed R through the heat exchanger 1. In winter, by switching the switching valve 5, the underground heat energy taken by the heat exchanger 1 and stored in the rock bed R is supplied to the snow-melting tray 2, and the snow-melting tray 2 can be used to melt the snow on the roof H and the road surface S.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com