Method for manufacturing surface acoustic wave device

A surface acoustic wave device, surface temperature technology, applied in electrical components, impedance networks, etc., can solve the problems that the aluminum layer is not suitable for high-frequency operation and high-power operation and has sufficient performance, the aluminum layer has no stability, and the power durability is not enough. High reliability, excellent power durability, effect of increasing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

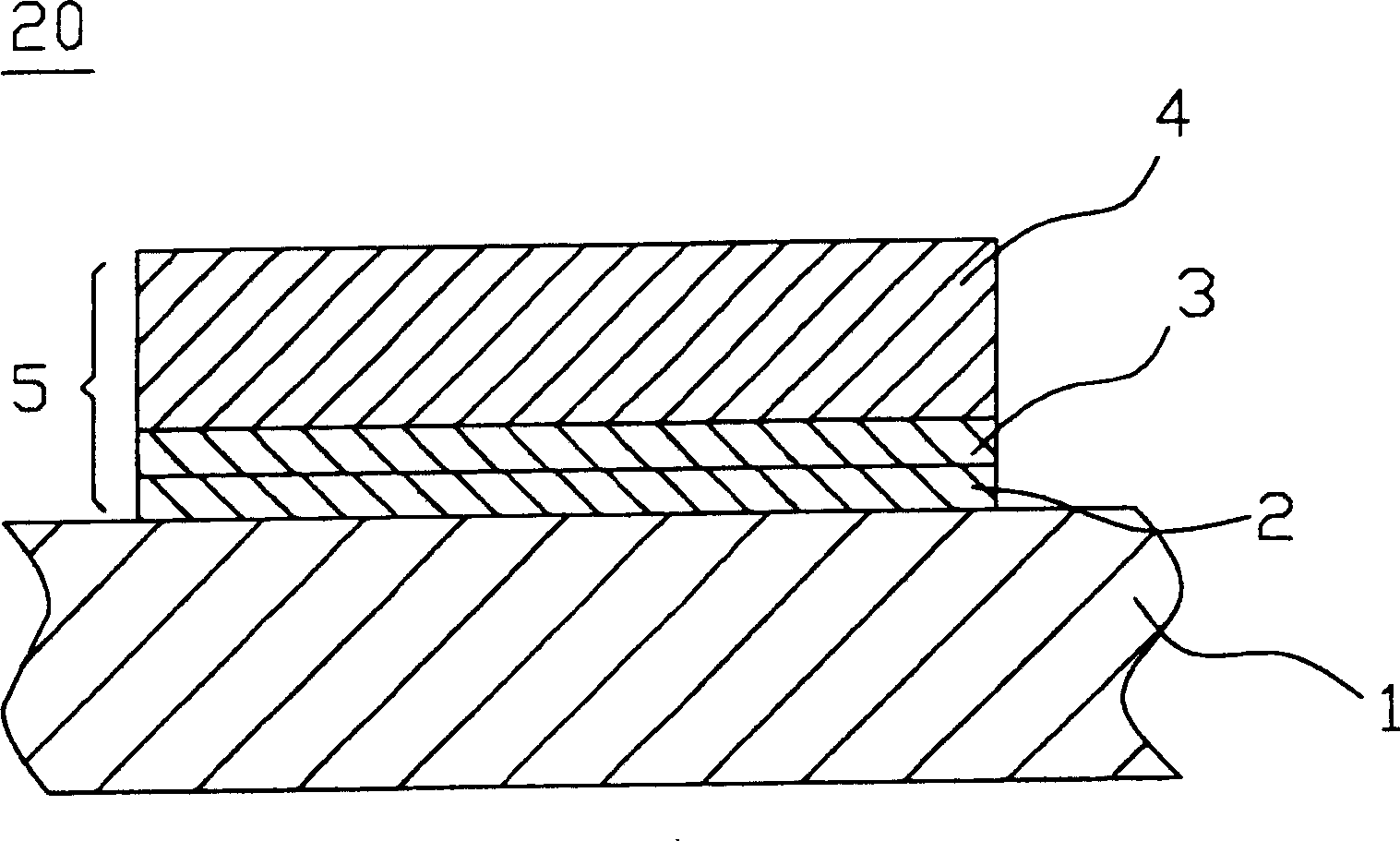

[0022] figure 1 Shown is a schematic sectional view of an example of a surface acoustic wave device produced by the production method of a preferred embodiment of the present invention.

[0023] figure 1 The shown surface acoustic wave device 20 includes a piezoelectric substrate 1, a first electrode layer 2 on the piezoelectric substrate 1, a second electrode layer 3 on the first electrode layer 2 and a The third electrode layer 4 .

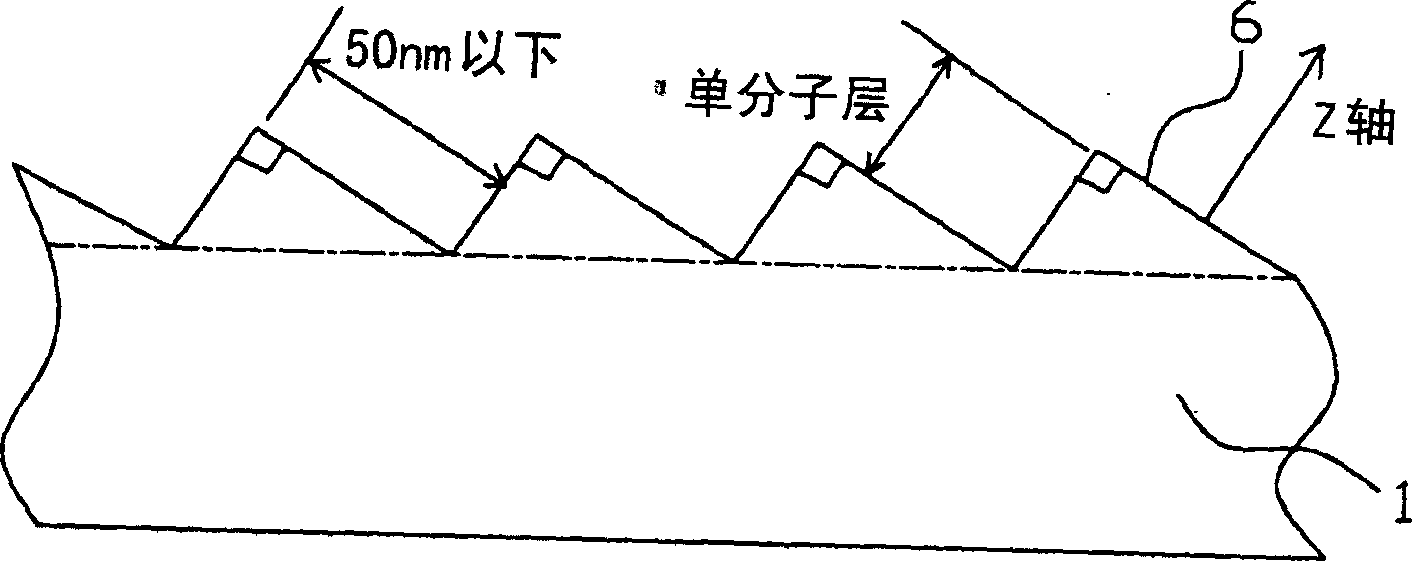

[0024] For the piezoelectric substrate 1, lithium niobate (LiNbO) with rotated Y-cut X-propagation is preferably used. 3 ) substrate or lithium tantalate (LiTaO 3 ) substrate. Such as figure 2 As shown, the surface of the piezoelectric substrate 1 has a stepped structure including, for example, a step face with a width of about 50 nm or less and a step with a width of a monomolecular layer.

[0025] The w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com