Patents

Literature

33results about How to "No significant increase in production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation dechlorinating catalyst for synthesizing trifluoroethylene and novel preprocessing process of carrier of catalyst

ActiveCN102211028AHigh selectivityImprove stabilityPreparation by dehalogenationCatalyst activation/preparationChemistryActivated carbon

The invention discloses a catalyst used for preparing trifluoroethylene by hydrogenating and dechlorinating trifluorochlor oethylene, comprising a first catalyst, a second catalyst and an assistant, wherein the first catalyst is one or combination of more than two of palladium, ruthenium and platinum, the second catalyst is Fe and / or Cu, and the assistant is selected from one or combination of more than two of V, Bi and K. The invention also discloses an activated carbon carrier preprocessing method of the catalyst for preparing the trifluoroethylene by hydrogenating and dechlorinating the trifluorochlor oethylene and an application of the prepared catalyst in trifluoroethylene preparation. The catalyst prepared by the method disclosed by the invention has the advantages of high catalytic activity and catalyst efficiency, good trifluoroethylene selectivity, strong reaction stability, mild reaction condition, simple catalyst preparation and processing process and the like.

Owner:SINOCHEM LANTIAN

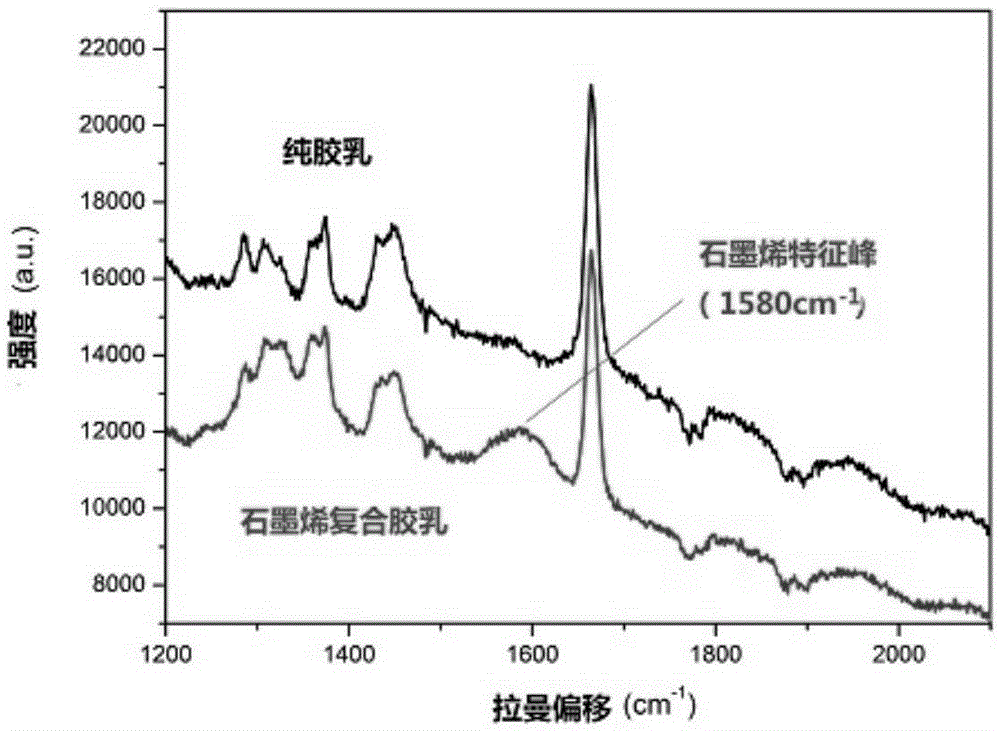

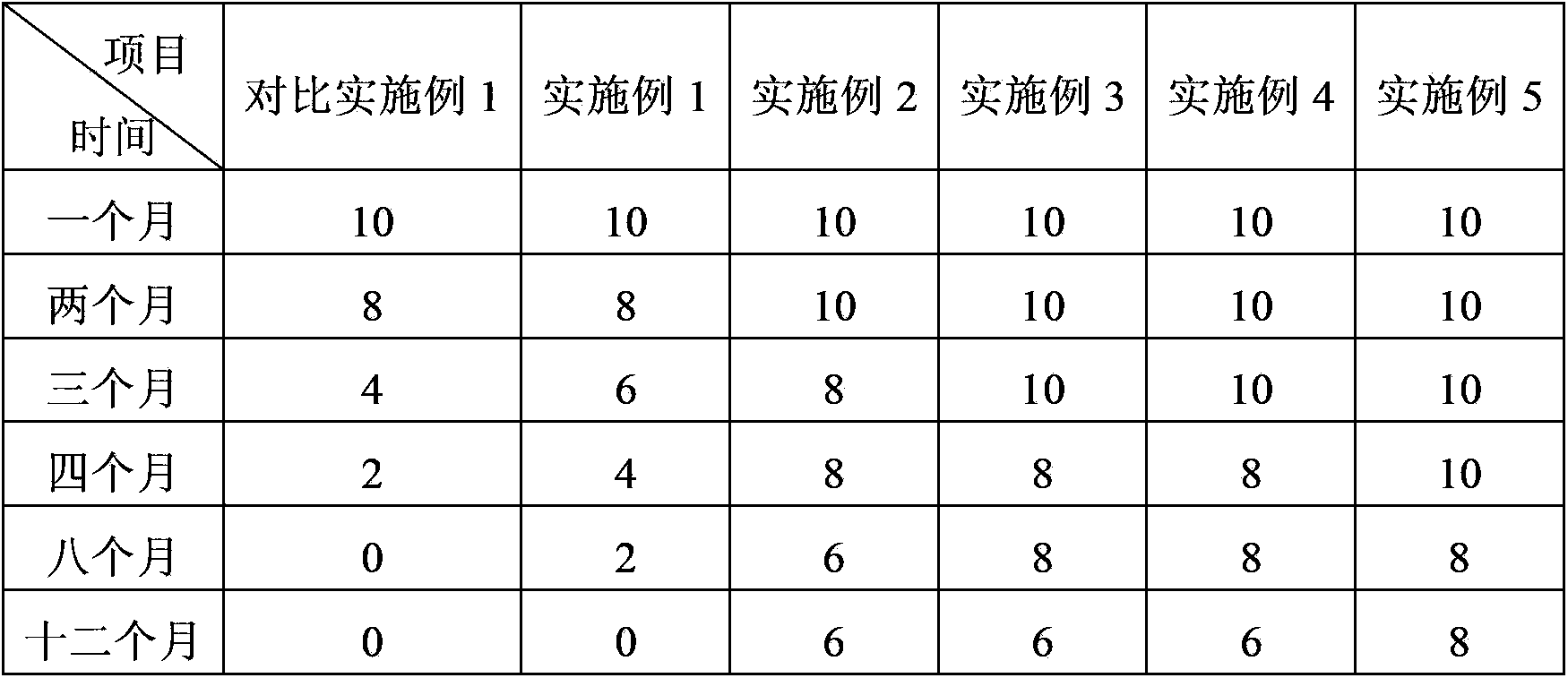

Method for preparing high-strength and high-isolation condoms from modified graphene/latex composite material

InactiveCN105237828AHigh strengthHigh barrier condomsMale contraceptivesCoatingsMedical equipmentVulcanization

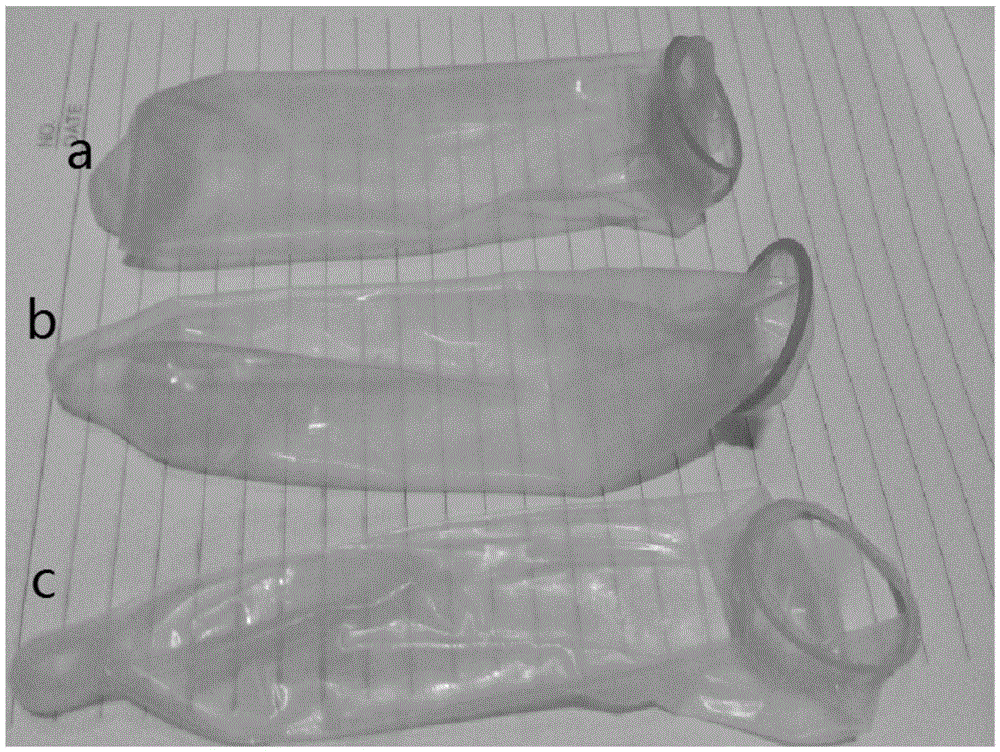

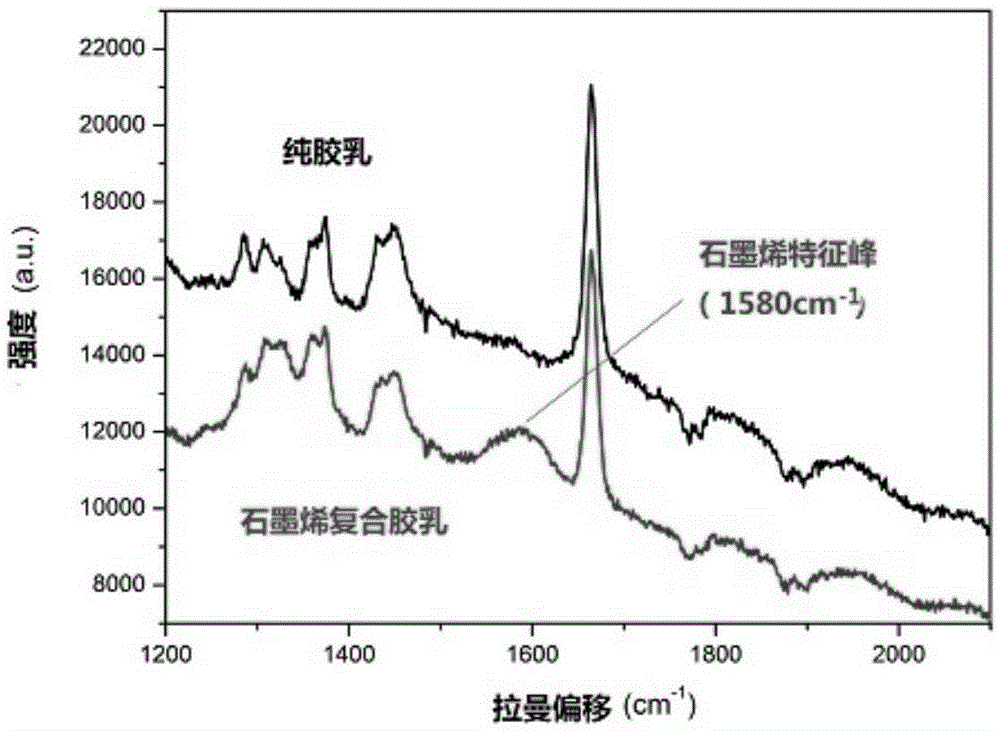

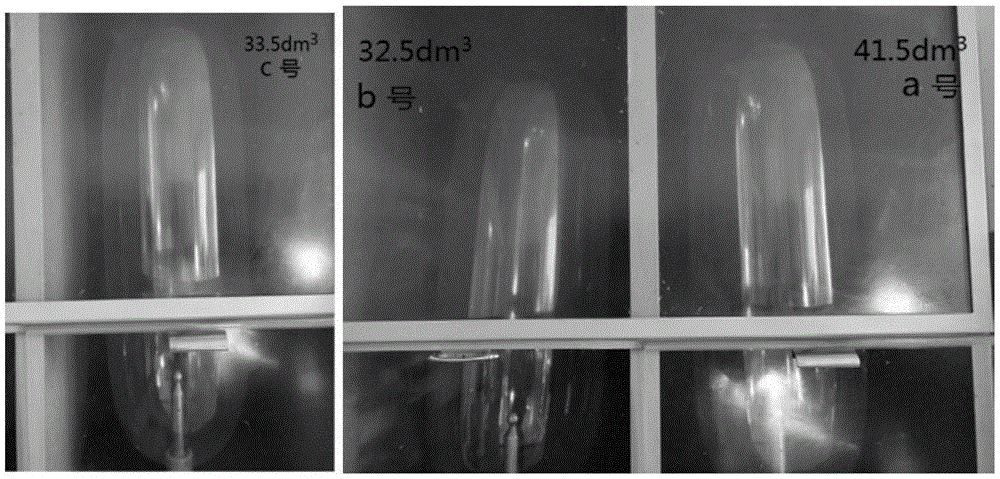

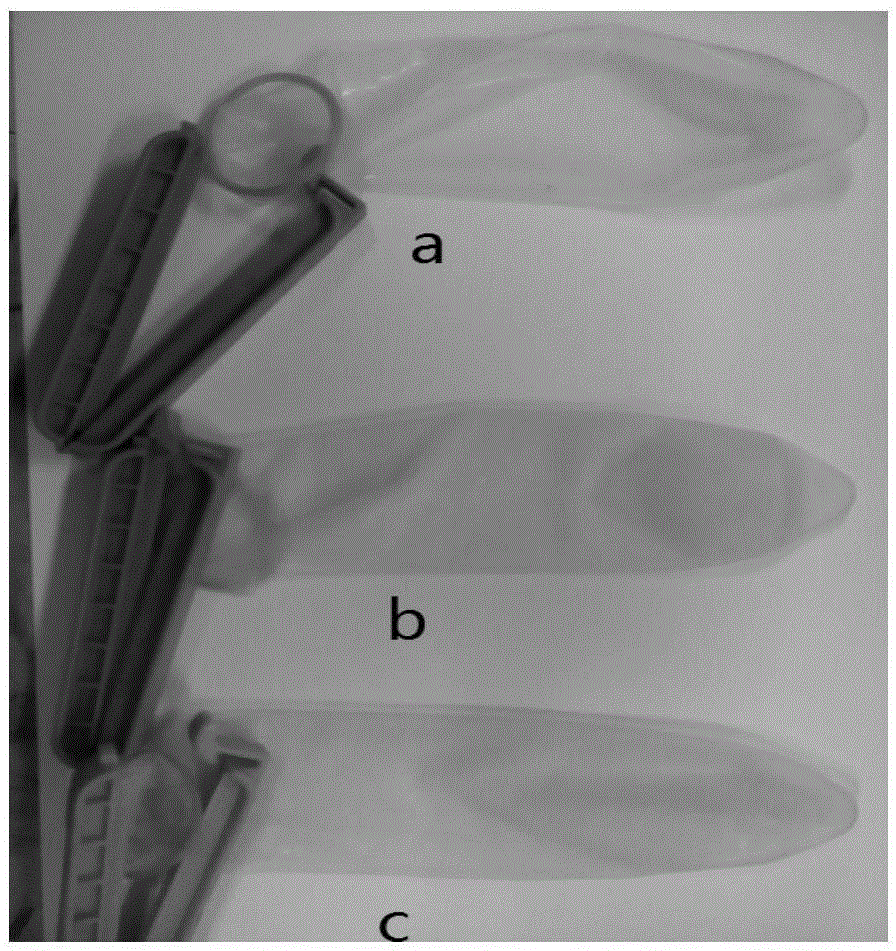

The invention relates to the fields of composite materials and medical equipment, in particular to a method for preparing high-strength and high-isolation condoms by utilizing a modified graphene / latex composite material. The method comprises the following steps: preparing modified graphene into a stable dispersion liquid, then carrying out direct recombination after latex compounding and prevulcanization curing period, or vulcanization recombination is finished at the same time in the period, and finally a compound rubber emulsion is finally obtained. After the curing of the compound rubber, the condom product is prepared by adopting a mold impregnating method. Compared with existing products, the grapheme compounded condom prepared by the invention has the advantages that the permeance of small-size viruses can be effectively blocked and the performance indexes such as tear resistance, blasting volume and ultimate elongation under same thickness are obviously improved. The method disclosed by the invention has the advantages of scientific principle, obvious characteristics, non-toxicity, innocuity, stable performance, high matching degree with prior art for condom production and the like.

Owner:LIAONING LANJING TECH CO LTD

Preparing method for high-strength high-isolation condom comprising modified graphene/latex interlayer

InactiveCN105237829ATransmission probability reduction and suppressionImprove comfortCoatingsHigh isolationHigh intensity

The invention relates to the field of composite materials and medical instruments, in particular to a preparing method for a high-strength high-isolation condom comprising a modified graphene / latex interlayer. The preparing method includes the steps that stable dispersion liquid prepared by modified graphene, latex liquid and common auxiliaries are mixed evenly to prepare compound latex liquid; a three-time impregnation process is adopted for forming, conventional latex liquid is used for impregnation in first-time and third-time impregnation, and the modified graphene / latex compound latex liquid is used as impregnation liquid in second-time impregnation to obtain the condom which is provided with conventional latex films on the innermost surface and the outermost surface and a modified graphene / latex compound material film interlayer in the middle to be of a sandwich structure finally. The prepared composite grapheme condom has the characteristic of blocking penetration of small-size viruses. Tear resistance and other indexes are obviously improved, and the blasting volume and the ultimate elongation rate are obviously increased on the premise of the same size. The high-strength high-isolation condom has the advantages of being scientific in principle, poisonless, harmless, stable in performance and capable of being matched with the current condem production process easily, and characteristics are remarkable.

Owner:LIAONING LANJING TECH CO LTD

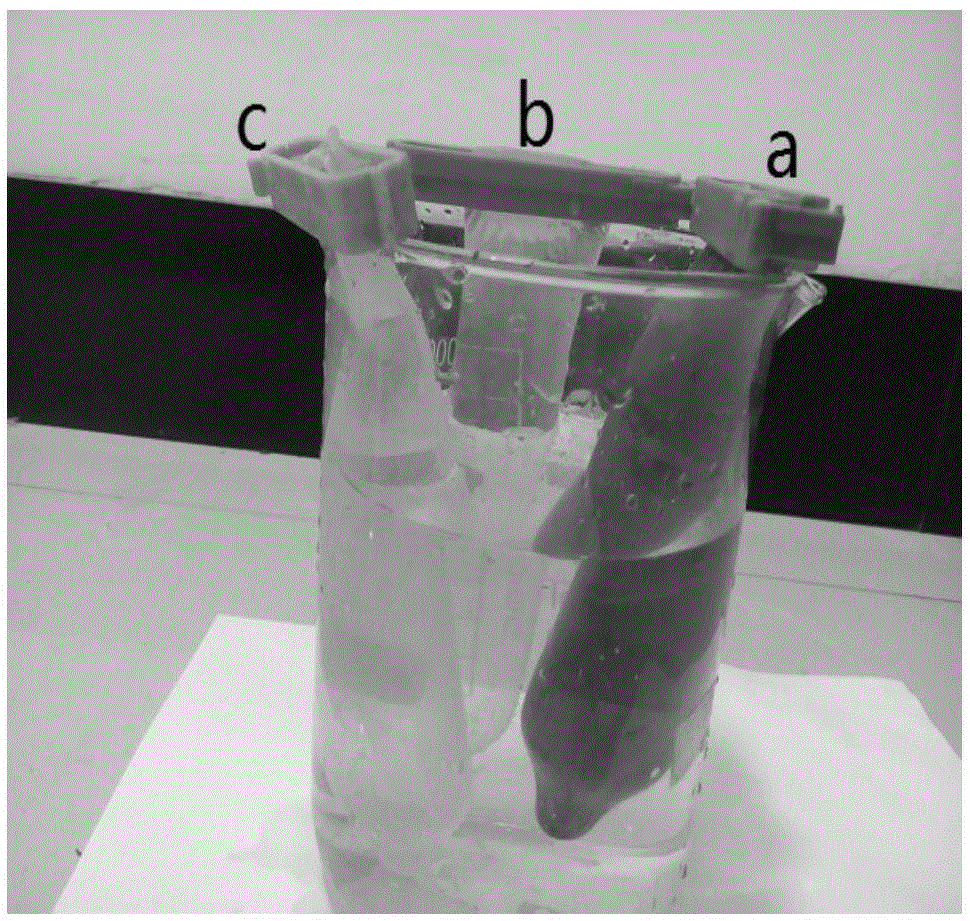

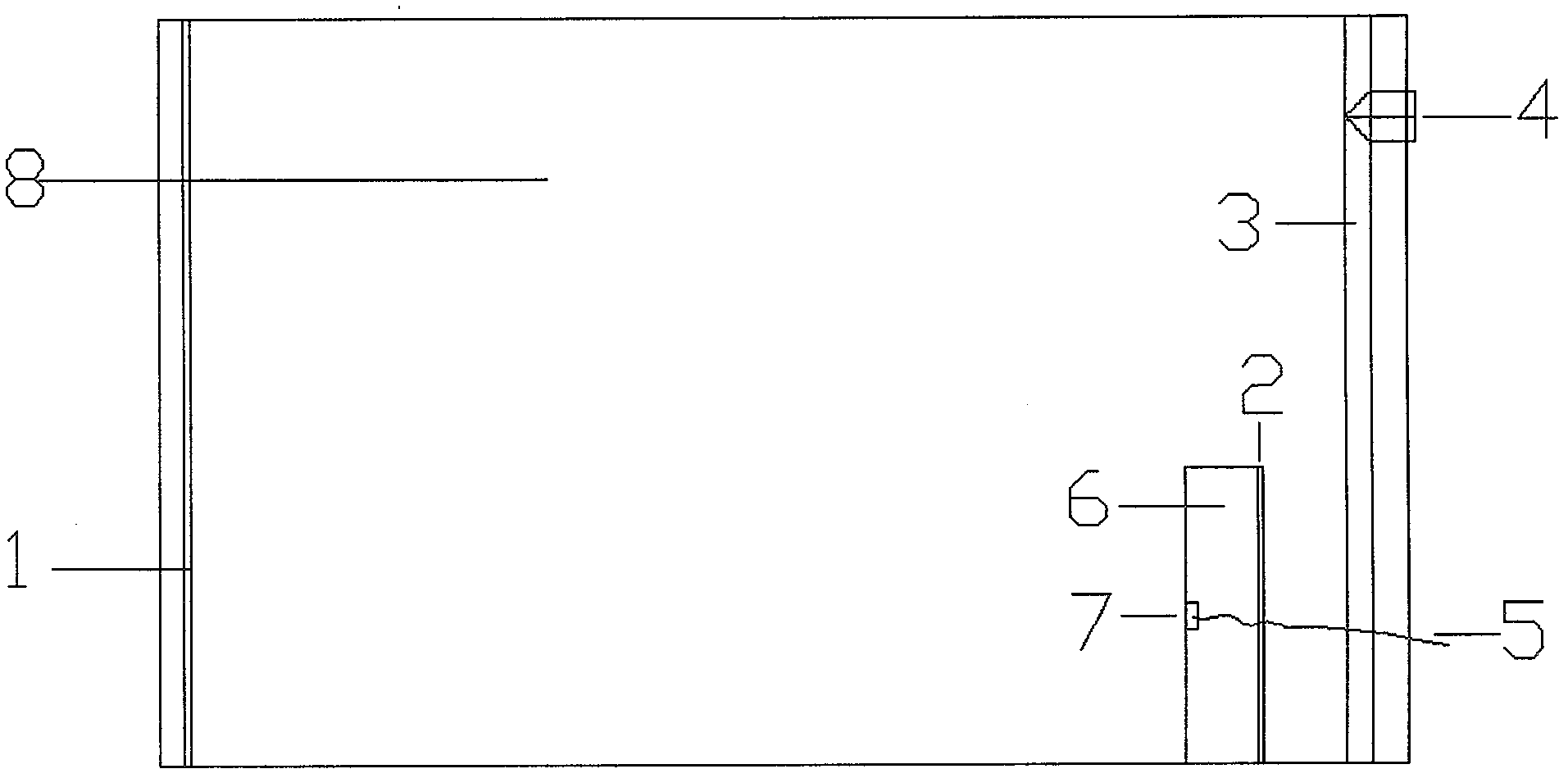

Vacuum garbage bag

InactiveCN102372140AIncrease production costEnsure permanent airtightBagsSacksProcess engineeringChemical plant

The invention discloses a novel garbage bag, which is applicable to the collection, temporary storage, transfer and final disposal of production wastes in hospitals, laboratories, chemical plants, essence and perfumery plants and other occasions. On the basis of the existing plastic garbage bag, the double faced adhesive tape quick seal technology is utilized, meanwhile, according to the bionics principle, the vein valve one-way valve principle is flexibly applied in the vacuum garbage bag, and accordingly, on the premise of not greatly increasing the production cost, the garbage is vacuumized, closed, compressed, reduced and packed in an anoxybiotic way. The vacuum garbage bag specifically comprises 8 bag bodies and 6 check valves (ensuring the smooth vacuum draw and successful vacuum operation), wherein an annular seal belt 4 is respectively arranged at the opening of each bag body, and covers a preset adhesive 3 (used for sealing the loaded bag). The invention aims to overcome the defects of the existing garbage bag technology, and provides the novel garbage bag which has a simple structure, convenience in processing, low production cost, environmental-friendly efficiency and complete functions.

Owner:石峰

On-line rust-proof method for twisted steel

InactiveCN102392210AHigh surface glossMeet the requirements of continuous productionSolid state diffusion coatingWater vaporOxygen

The invention discloses an on-line rust-proof method for twisted steel. The method comprises the following step: ejecting steam or mixture of steam and oxygen to the twisted steel subjected to waste heat processing so as to generate a protective layer on the surface of the twisted steel. According to the on-line rust-proof method for twisted steel, the twisted steel with good surface gloss can be obtained. In addition, the method can satisfy the continuous production requirement of the twisted steel, and the production cost can not be obviously increased.

Owner:LAIWU IRON & STEEL GRP

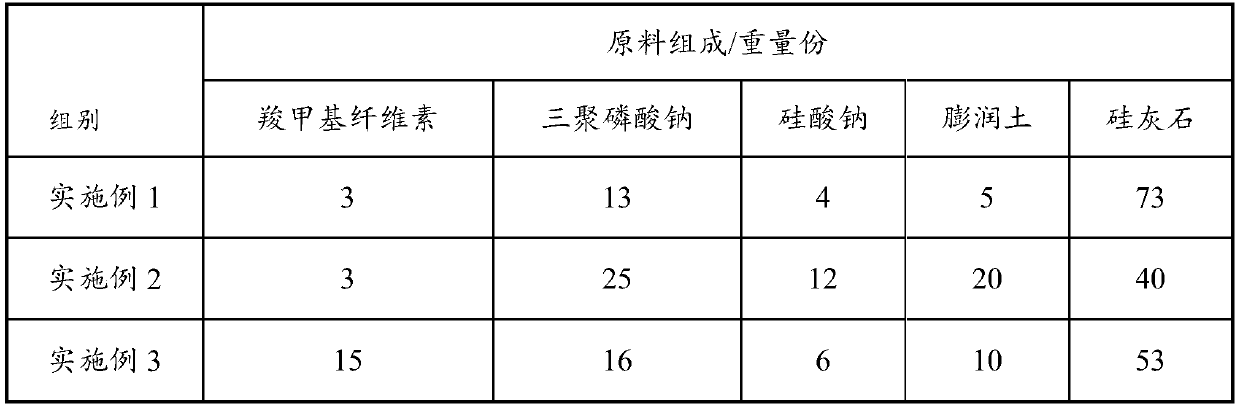

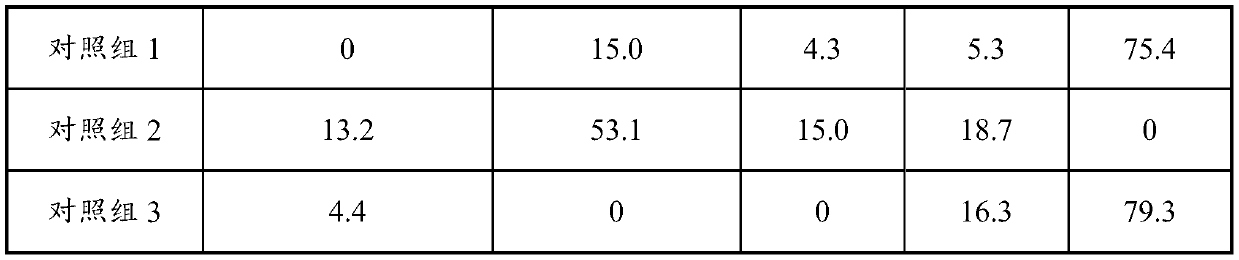

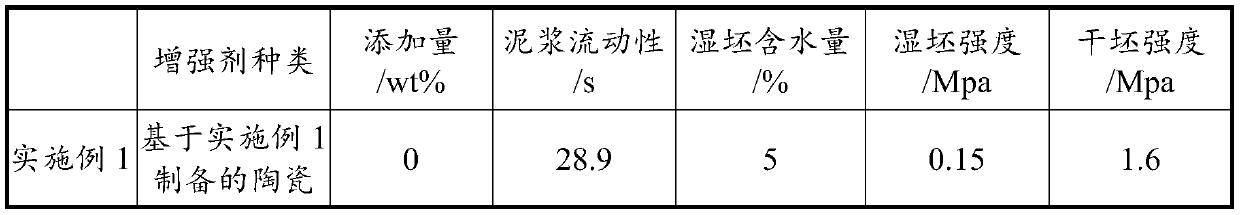

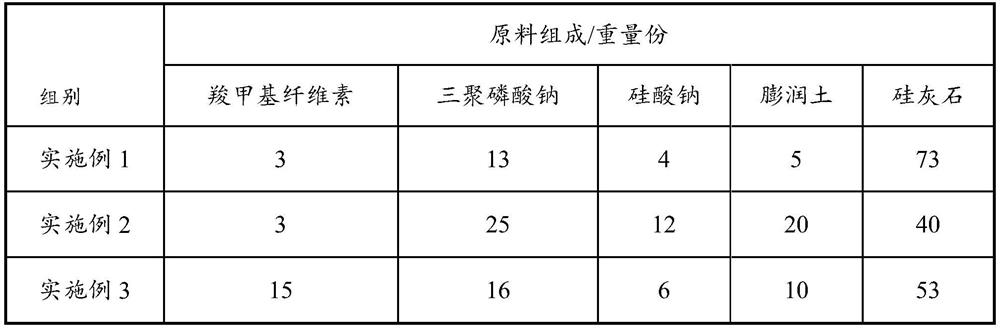

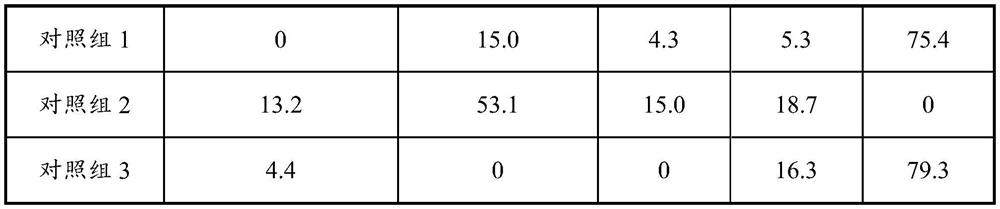

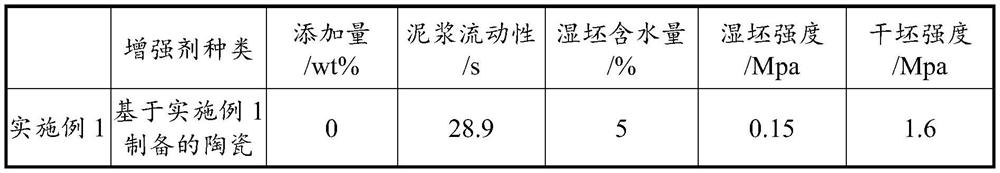

Ceramic green body reinforcing agent as well as preparation method and application thereof

The invention discloses a ceramic green body reinforcing agent which comprises the following components in parts by weight: 3-15 parts of carboxymethyl cellulose, 13-25 parts of sodium tripolyphosphate, 4-12 parts of sodium silicate, 5-20 parts of bentonite and 40-73 parts of wollastonite. The reinforcing agent can significantly improve the wet body strength of a ceramic green body with a high barren material content; the reinforcing agent can be ball-milled together with ceramic green body raw materials, so that the raw materials are fully and uniformly mixed, and the uniformity of wet body strength is further ensured; the raw materials of the reinforcing agent are easy to obtain, low in cost and environment-friendly and the production cost of ceramic products is not obviously improved. The adding and using process is very simple, and industrial production can be achieved. Meanwhile, the invention further provides a preparation method and application of the ceramic green body reinforcing agent.

Owner:清远市简一陶瓷有限公司 +1

Hydrogenation dechlorinating catalyst for synthesizing trifluoroethylene and novel preprocessing process of carrier of catalyst

ActiveCN102211028BHigh catalytic activityImprove reaction stabilityPreparation by dehalogenationCatalyst activation/preparationActivated carbonPlatinum

The invention discloses a catalyst used for preparing trifluoroethylene by hydrogenating and dechlorinating trifluorochlor oethylene, comprising a first catalyst, a second catalyst and an assistant, wherein the first catalyst is one or combination of more than two of palladium, ruthenium and platinum, the second catalyst is Fe and / or Cu, and the assistant is selected from one or combination of more than two of V, Bi and K. The invention also discloses an activated carbon carrier preprocessing method of the catalyst for preparing the trifluoroethylene by hydrogenating and dechlorinating the trifluorochlor oethylene and an application of the prepared catalyst in trifluoroethylene preparation. The catalyst prepared by the method disclosed by the invention has the advantages of high catalytic activity and catalyst efficiency, good trifluoroethylene selectivity, strong reaction stability, mild reaction condition, simple catalyst preparation and processing process and the like.

Owner:SINOCHEM LANTIAN

Production method of composite phosphate

InactiveCN106082152ANo significant increase in production costsDisperse fastPhosphatesProduction lineHigh concentration

The invention discloses a production method of composite phosphate. The production method includes: using monomer phosphate or physically-mixed phosphate as the raw material, controlling the temperature to be at 200-40 DEG C, adding a certain proportion of water under a stirring state, controlling the temperature of the phosphate in different ranges, and using the hydrolysis of the phosphate to produce the composite phosphate of different proportions and properties according to different water adding proportions and temperatures. The production method has the advantages that the dissolving speed of the produced composite phosphate can reach the dissolving speed of chemical mixing, caking of the produced composite phosphate in water is avoided, the high-concentration composite phosphate is fast in dispersing, and the normal-concentration composite phosphate is fast in dissolving; the phosphate production cost of factories is not increased evidently, and only the cooling equipment of an original phosphate production line needs to be slightly modified.

Owner:苏州闻达食品配料有限公司

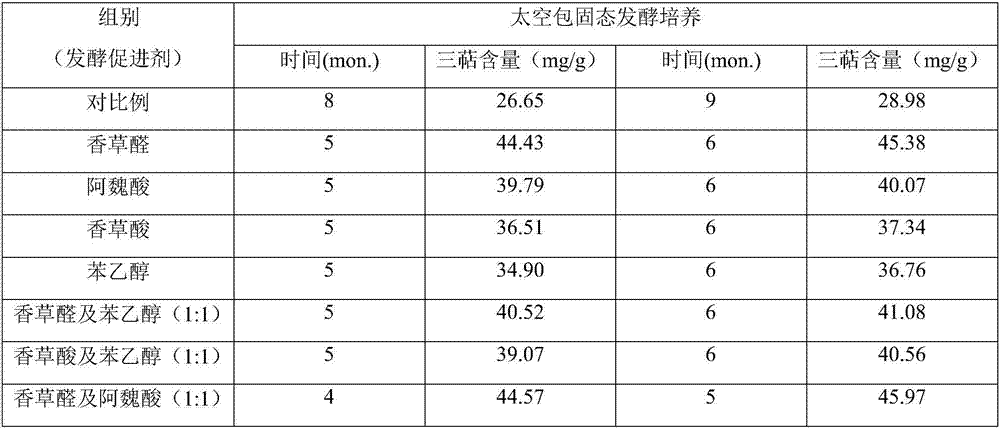

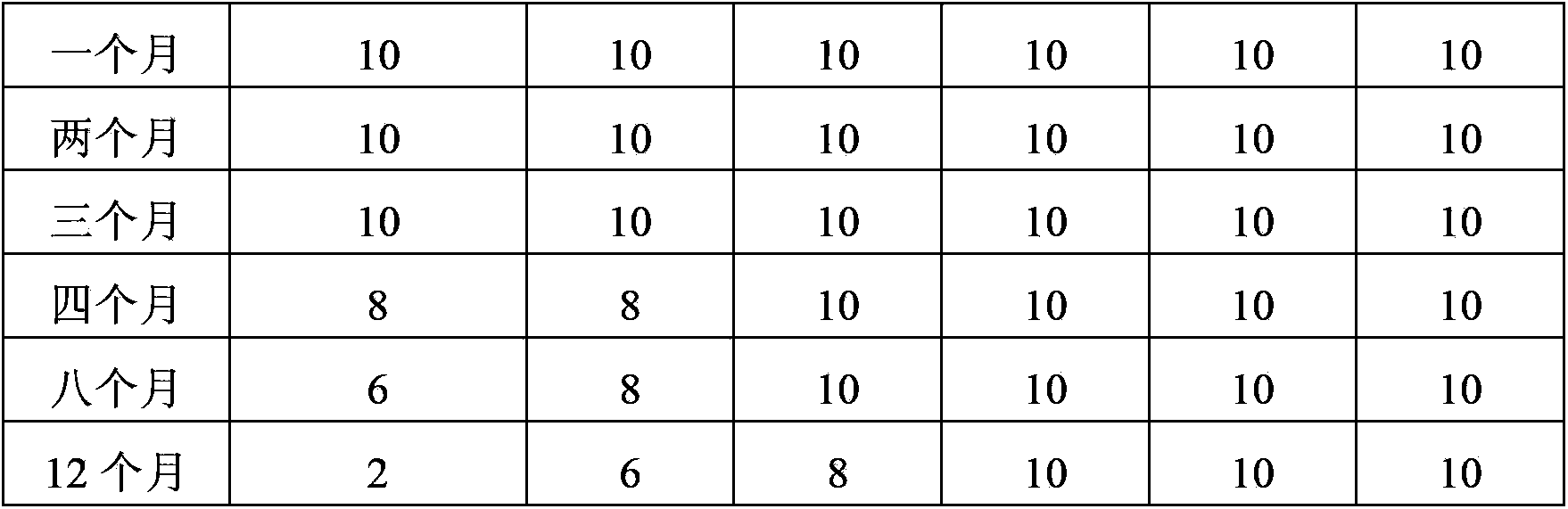

Antrodia camphorate growth promoter and method for fast producing antrodia camphorate through fermentation

InactiveCN106883010AReduce the probability of contamination with bacteriaIncrease production costFungiMagnesium fertilisersChemistryBioactive substance

The invention relates to an antrodia camphorate growth promoter and a method for fast producing antrodia camphorate through fermentation. The method comprises the processes of inclined surface culture, liquid state seed preparation, liquid state fermentation and solid state fermentation. In each fermentation process, one kind or the combination of several kinds of aromatic compounds such as vanillina can be added, so that the culture period of producing antrodia camphorate mycelia and encarpium through fermentation can be greatly shortened; the content of bioactive substances of antrodia camphorate triterpene is improved. Compared with the existing study and report technology, the antrodia camphorate growth promoter and the method have the advantages that the process is simple; the efficiency is high; the trace growth promoter is used; the goal of fast producing the antrodia camphorate mycelia and encarpium can be achieved; the fermentation period is reduced by more than 50 percent through being compared with that of a conventional method; the content of the antrodia camphorate triterpene is improved by 60 percent or higher; the production cost is reduced; good industrial application prospects are realized.

Owner:JIANGNAN UNIV

Power lithium battery tab thermal composite molding process

ActiveCN110600667AStable structureNo significant increase in production costsLi-accumulatorsCell component detailsElectrical conductorThermal compression

The invention discloses a power lithium battery tab thermal composite molding process. The process specifically comprises the following steps: step one, preparing a metal conductor strip; step two, preparing tab tape; step three, heating the prepared metal conductor strip, and feeding the prepared tab tape to a surface of the heated metal conductor strip to perform thermal-compression, and stopping heating the metal conductor strip after the thermal-compression is finished. The tab obtained through the power lithium battery tab thermal composite molding process is stable in structure, and thethermal conductivity and the insulativity exceed the like products on the market, and the production cost is free from great increasing.

Owner:厦门纬达科技股份有限公司

Dual-component polyurethane waterproof paint, B component, B component stabilizing agent and preparation method

ActiveCN103911065ANo significant increase in production costsThe preparation process is stablePolyurea/polyurethane coatingsPolyolToluene diisocyanate

The invention discloses a dual-component polyurethane waterproof paint, a B component, a B component stabilizing agent and a preparation method. The preparation method of the B component stabilizing agent of the dual-component polyurethane waterproof paint comprises the following steps: 1)mixing 30-35% of polyether glycol, 16-20% of plasticizer and 5.0-7.0% of toluene diisocyanate and reacting to obtain a material liquid A; and 2)mixing the material liquid A, 0.01-0.02% of catalyst and 40-45% of diluent, reacting until the NCO% content is 1.0-1.05% to obtain the product. The B component stabilizing agent can greatly improve the stability of the B component, deposition generation can be effectively reduced, and the expiration date of the paint is prolonged. The B component enables long-term stabilization and storage under high temperature and low temperature. The cost production of the dual-component polyurethane waterproof paint is not obviously increased, and the product comprehensive property is high. The preparation method of the invention has the advantages of stable technology, easy realization of industrial production, low cost and environmental protection.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Corundum cooling medium, related preparation method thereof and application thereof

InactiveCN102746014ASmall crystal sizeNo significant increase in production costsOther chemical processesHeat-exchange elementsFiberCarbon fibers

The invention relates to a corundum cooling medium which is a silicon carbide ball, carbon fiber-enhanced silicon carbide ball or graphite fiber-enhanced silicon carbide plate. The invention further provides a preparation method of the carbon fiber-enhanced silicon carbide ball or the graphite fiber-enhanced silicon carbide plate, an application of the silicon carbide ball, the carbon fiber-enhanced silicon carbide ball or the graphite fiber-enhanced silicon carbide plate used as the corundum cooling medium in the cooling of the corundum, a corundum quick cooling method, an obtained corundum abrasive material, and a mould made by the corundum abrasive material. According to the corundum cooling medium, the method and the application, the corundum is cooled by the corundum cooling medium, the cooling is quick, no potential safety hazard exists, the investment is little, and the cost is reasonable, an obtained corundum product is small in crystal size, and the product cost of the obtained corundum product can not be obviously increased, so that the corundum cooling medium, the method and the application are suitable for large-scale popularization and application.

Owner:王胜国 +1

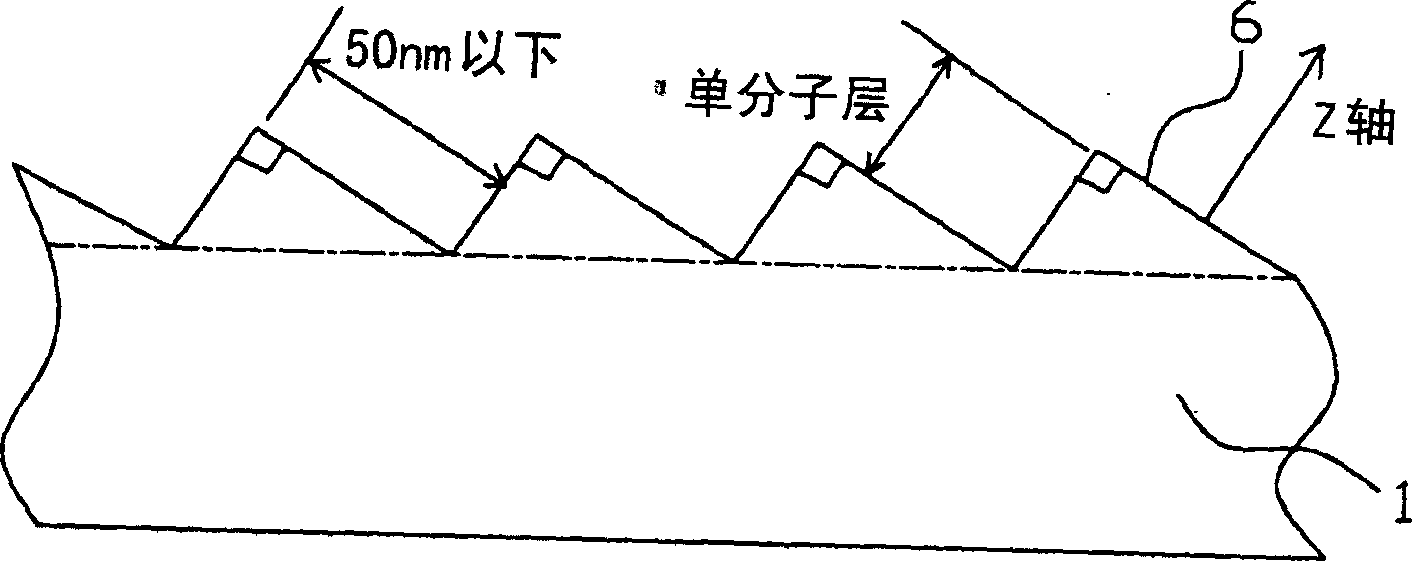

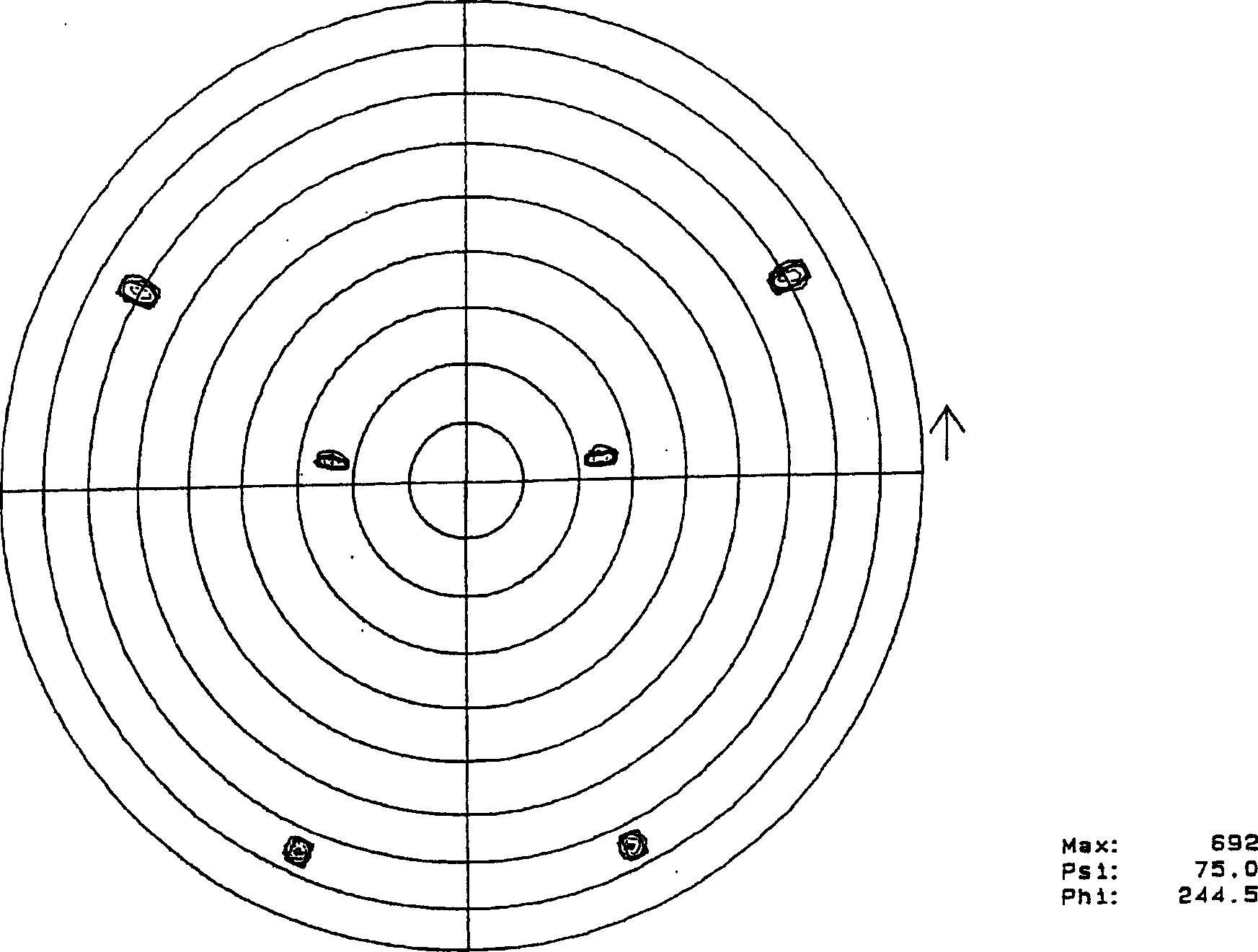

Method for manufacturing surface acoustic wave device

ActiveCN1543062AExcellent Power DurabilityHigh precisionImpedence networksOptoelectronicsInterdigital transducer

A piezoelectric substrate is provided with interdigital transducer electrodes including a first electrode layer, a second electrode layer, and a third electrode layer that is principally made of aluminum. The piezoelectric substrate has a stepped structure on the surface of the piezoelectric substrate, the stepped structure including terraces each having a width of about 50 nm or less and steps each having a width of a mono-molecular layer (e.g., about 14 ANGSTROM).

Owner:MURATA MFG CO LTD

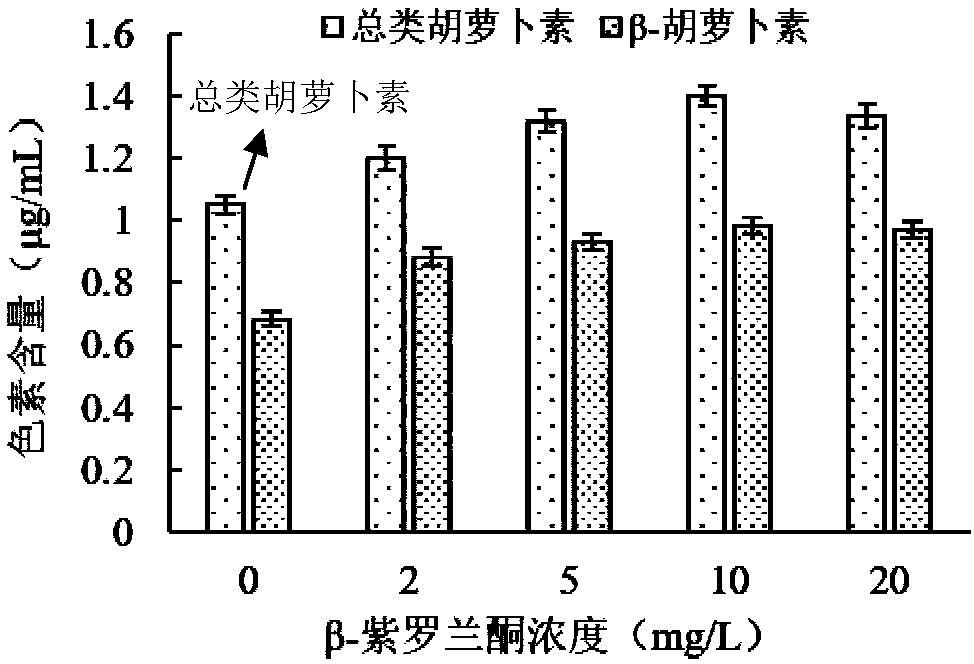

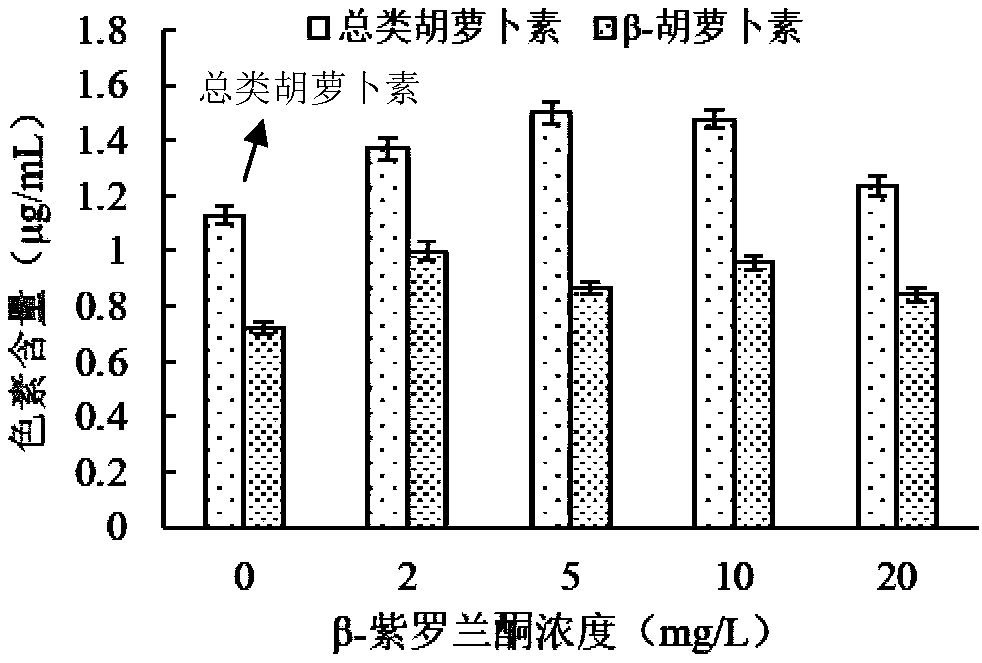

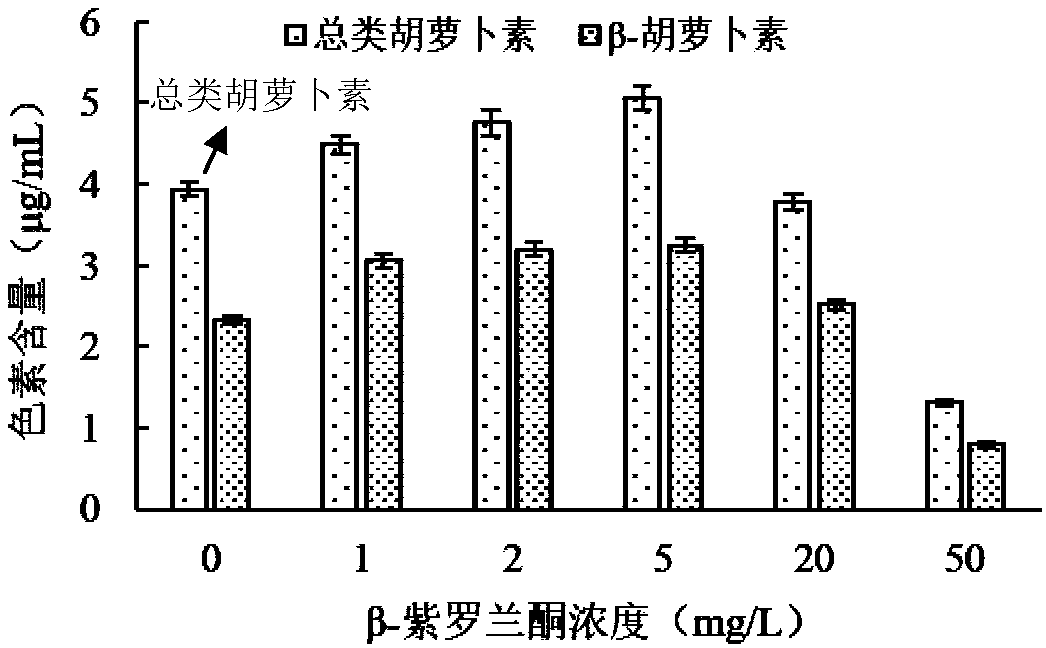

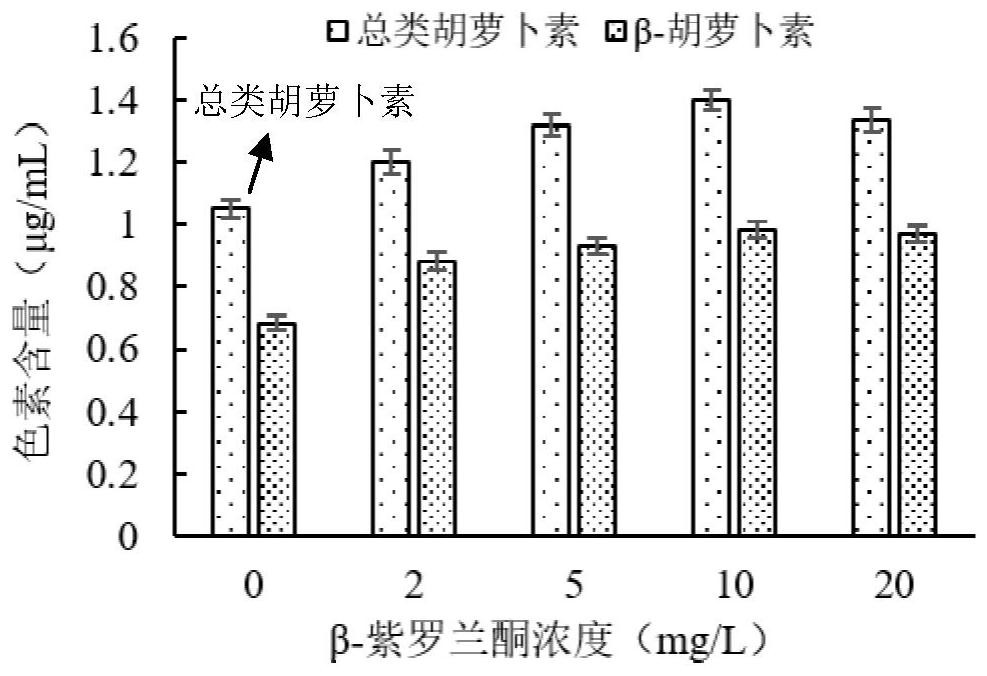

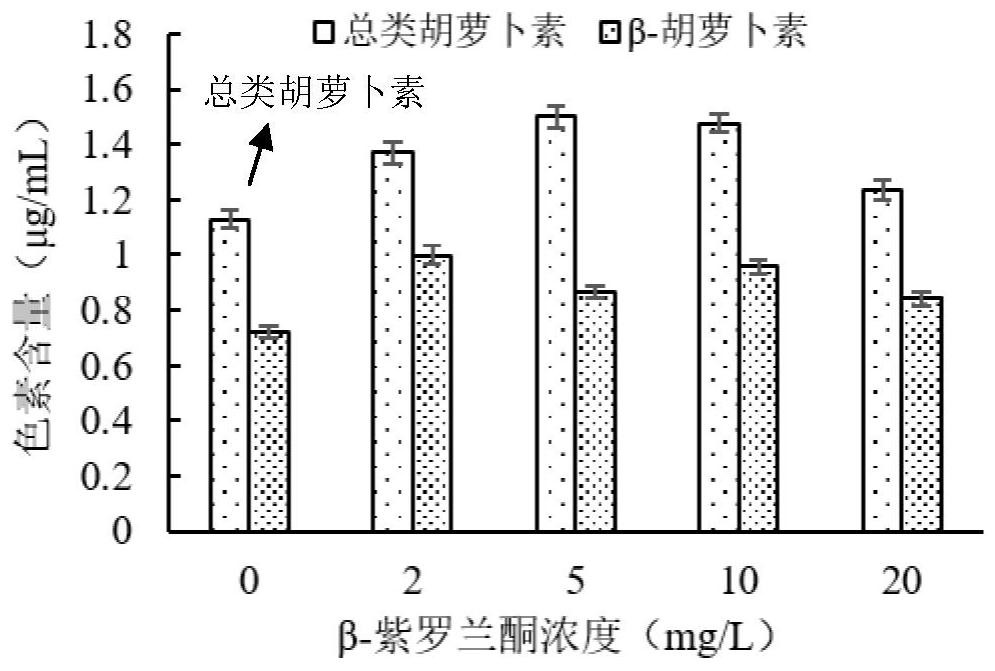

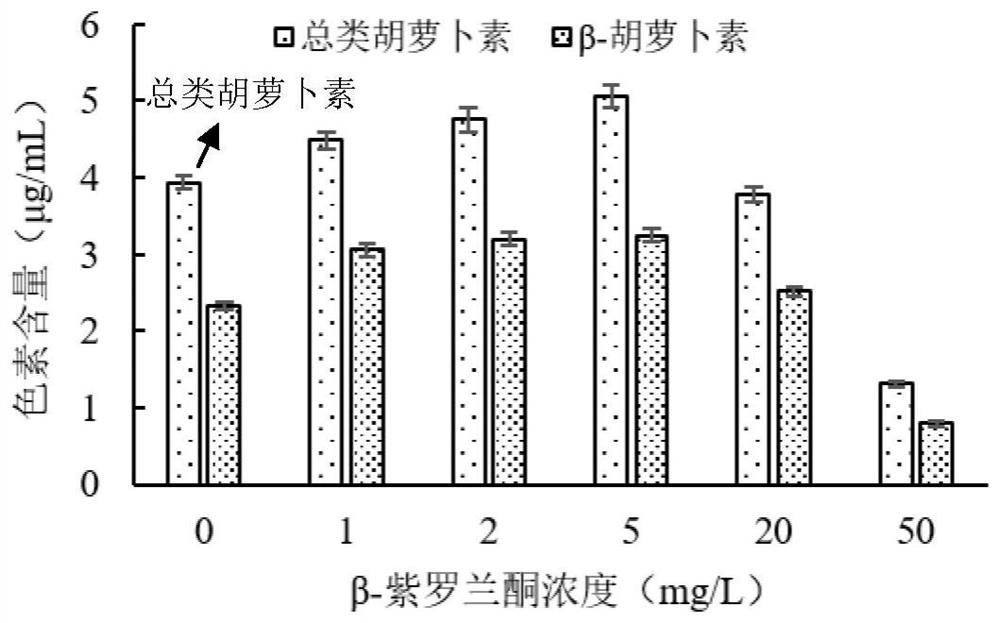

Method for promoting accumulation of carotenoids and beta-carotene in Dunaliella by using beta-ionone

ActiveCN108949888ASimple cultivation conditionsStrong stress resistanceMicroorganism based processesFermentationBlastochloris viridisDunaliella

The invention belongs to the technical field of food science, and discloses a method for promoting accumulation of carotenoids and beta-carotene in Dunaliella by using beta-ionone. The method comprises the following steps: carrying out induced culture on Dunaliella cells to be induced in a medium containing beta-ionone, accumulating beta-carotene in carotenoids and carotenoids in the algae cells,and then extracting a pigment. The Dunaliella cells to be induced are Dunaliella cells in a logarithmic phase and / or a stationary phase. The method of the invention is simple and feasible, is low-cost, and can significantly increase the yield of total carotenoids and beta-carotene; and Dunaliella is salt-tolerant single-celled green algae, requires simple culture conditions and is not easily contaminated by other microorganisms, which is beneficial to large-scale cultivation and meets the standards of industrial mass production.

Owner:SOUTH CHINA UNIV OF TECH

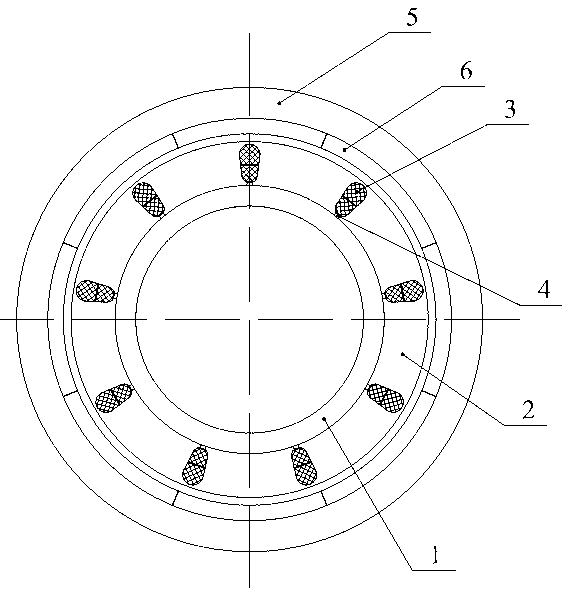

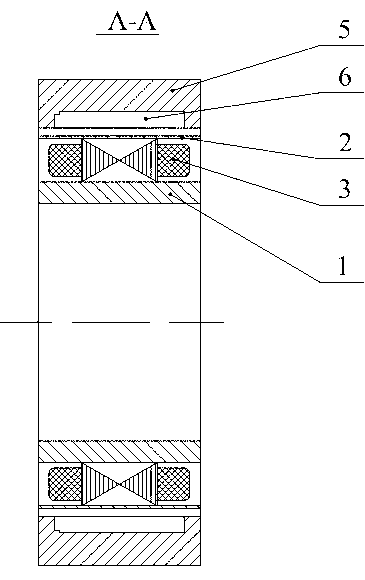

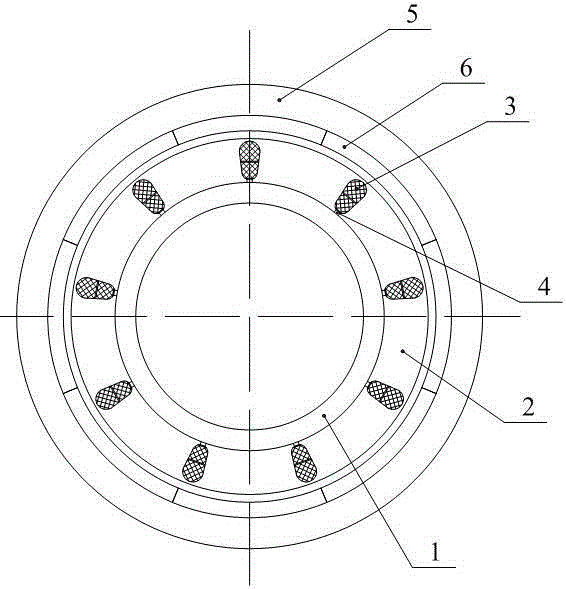

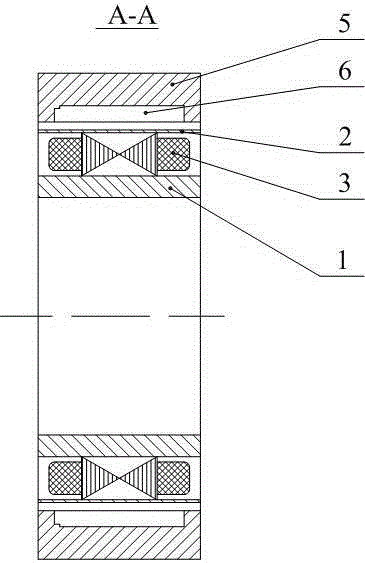

Shafting-free outer rotor permanent magnetic synchronous motor capable of reducing slot effect

ActiveCN103124126AReduce coggingIncrease production costMagnetic circuit rotating partsSynchronous machine detailsSynchronous motorPhysics

A shafting-free outer rotor permanent magnetic synchronous motor capable of reducing a slot effect belongs to the field of motors and solves the problem that motor performance is reduced due to the fact that the existing permanent magnetic synchronous motor with a slot structure has the slot effect. The shafting-free outer rotor permanent magnetic synchronous motor comprises a stator casing, a stator and a rotor. The stator casing is arranged on an inner circle surface of the stator, the stator is arranged inside the rotor, and an even air gap exists between the stator and the rotor. The stator comprises a stator yoke, stator slots, stator windings and slot wedges. A plurality of stator slots are arranged inside the annular stator yoke along the peripheral direction evenly, the stator windings are embedded in the stator slots, and the slot wedges are arranged between openings of the stator slots and the stator casing and used for fixing the stator windings. The rotor comprises a rotor yoke and a plurality of rotor magnetic poles. A plurality of rotor magnetic poles are arranged on an inner circle surface of the rotor yoke evenly.

Owner:黑龙江工大华工电机科技有限公司

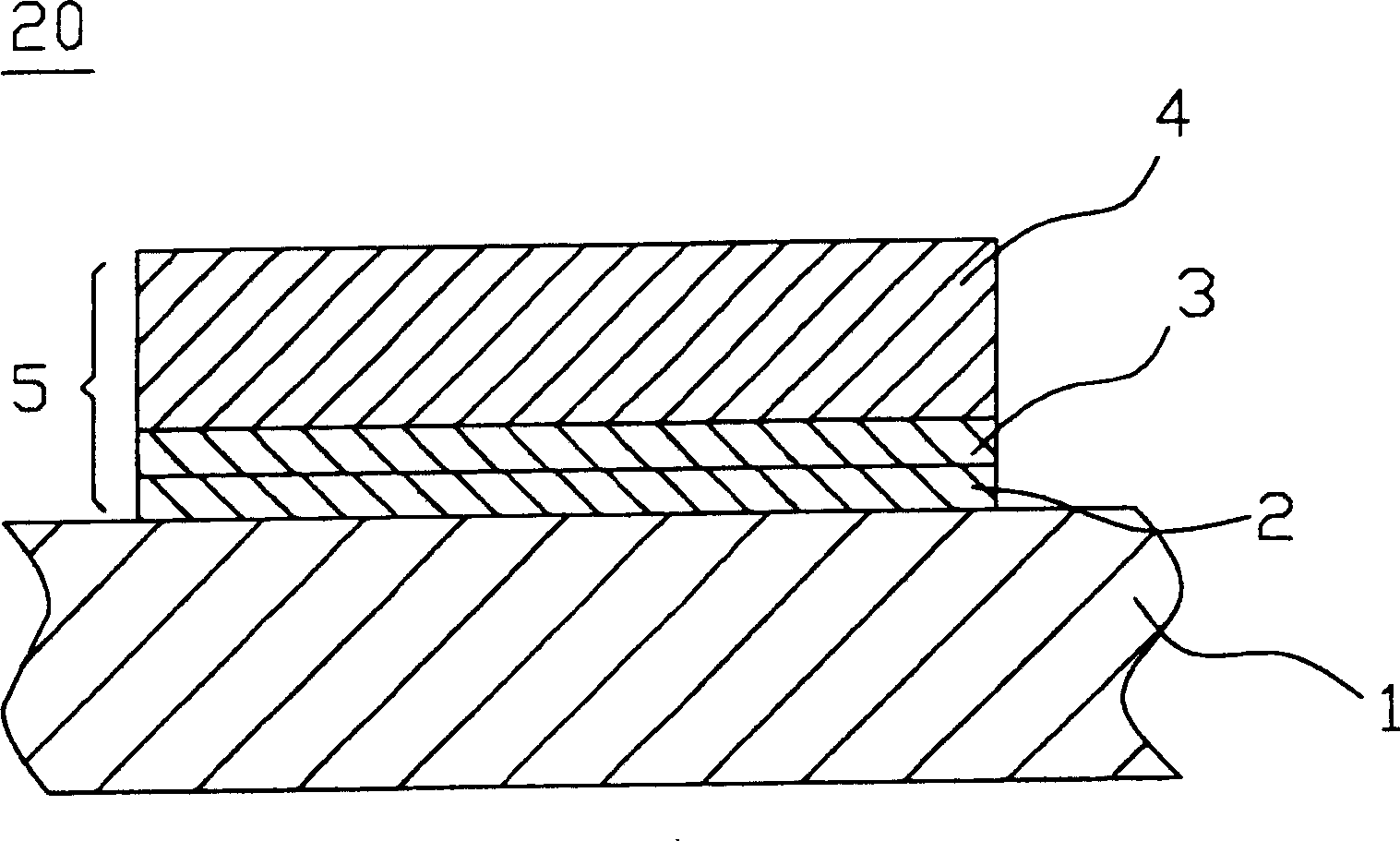

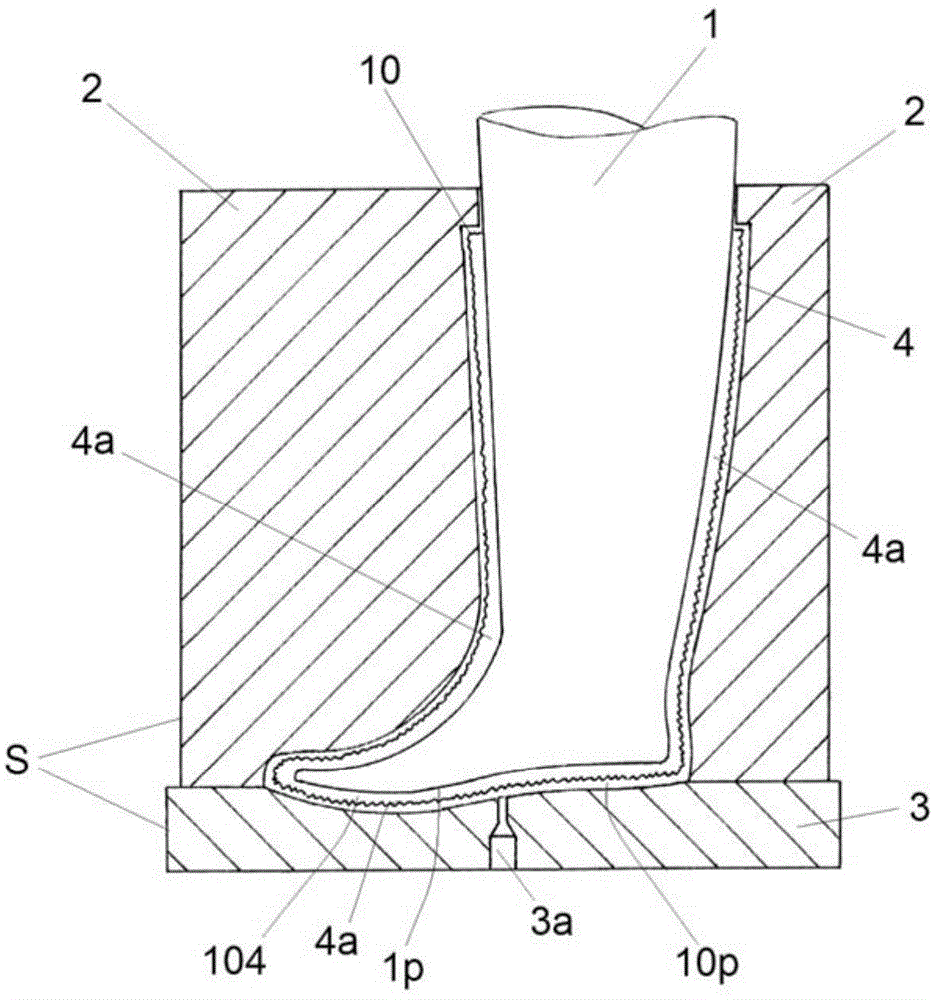

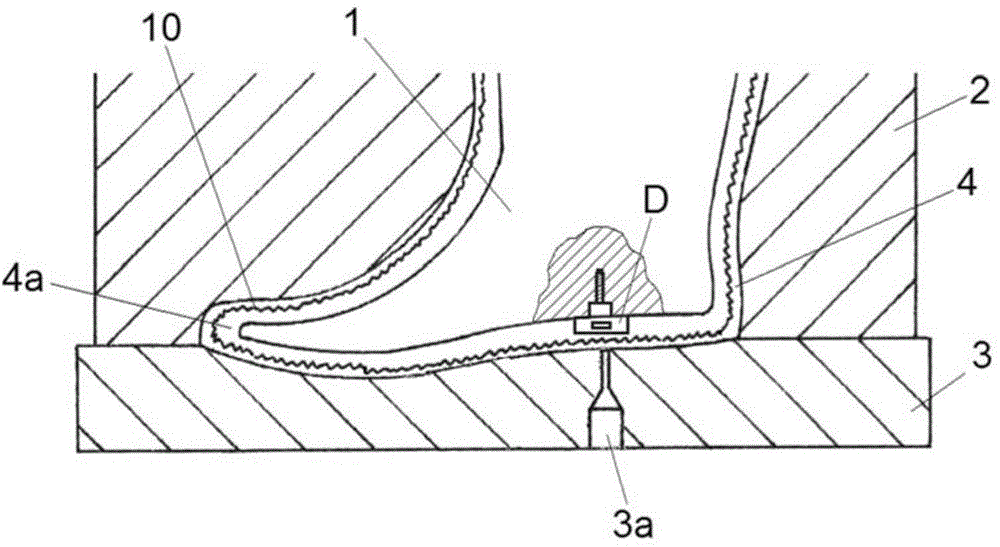

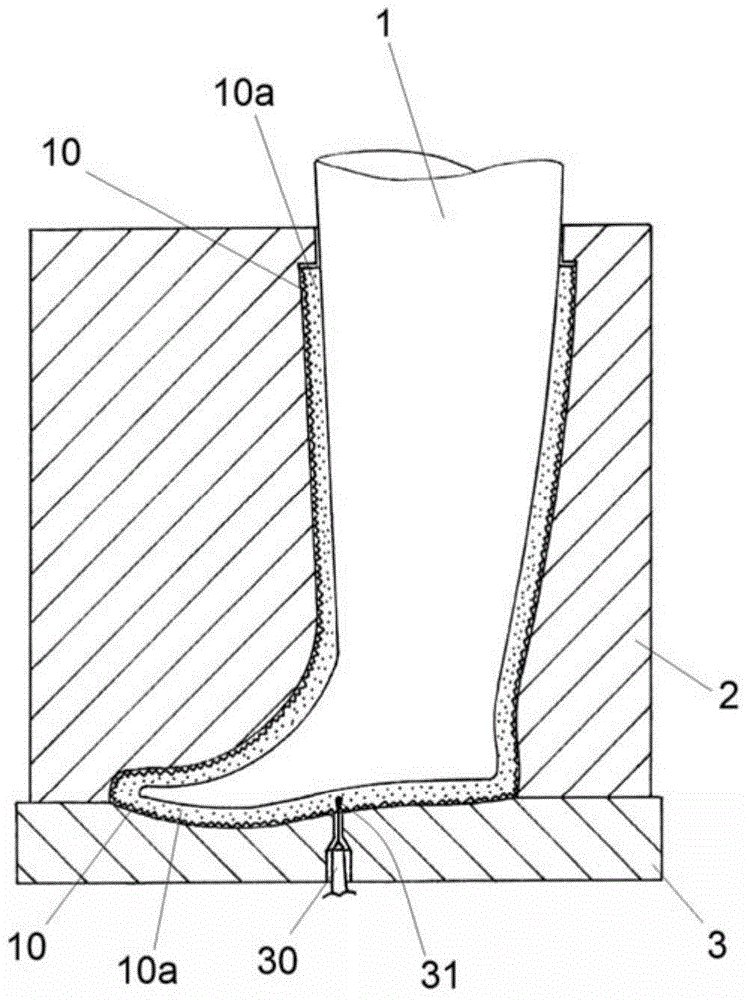

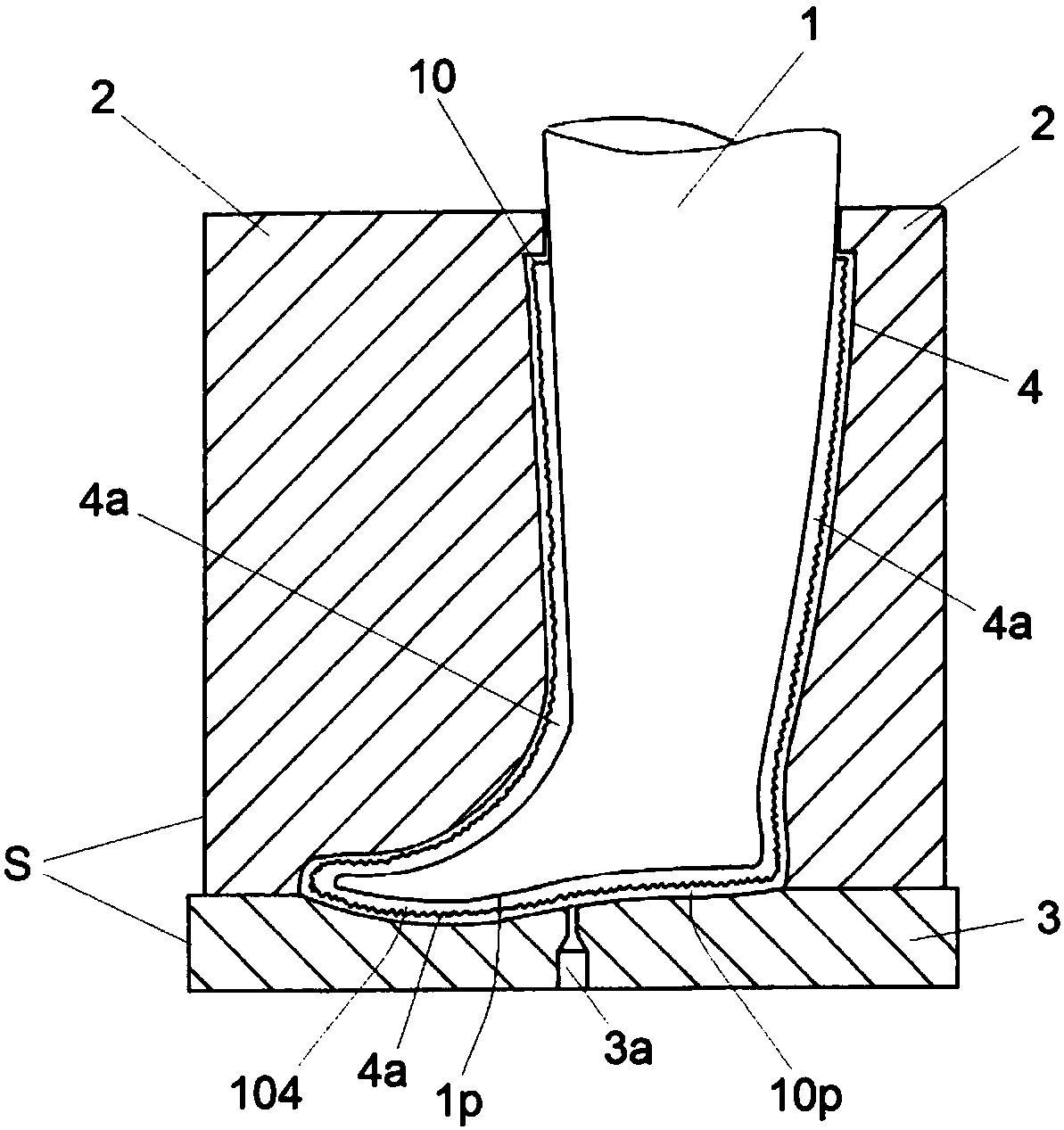

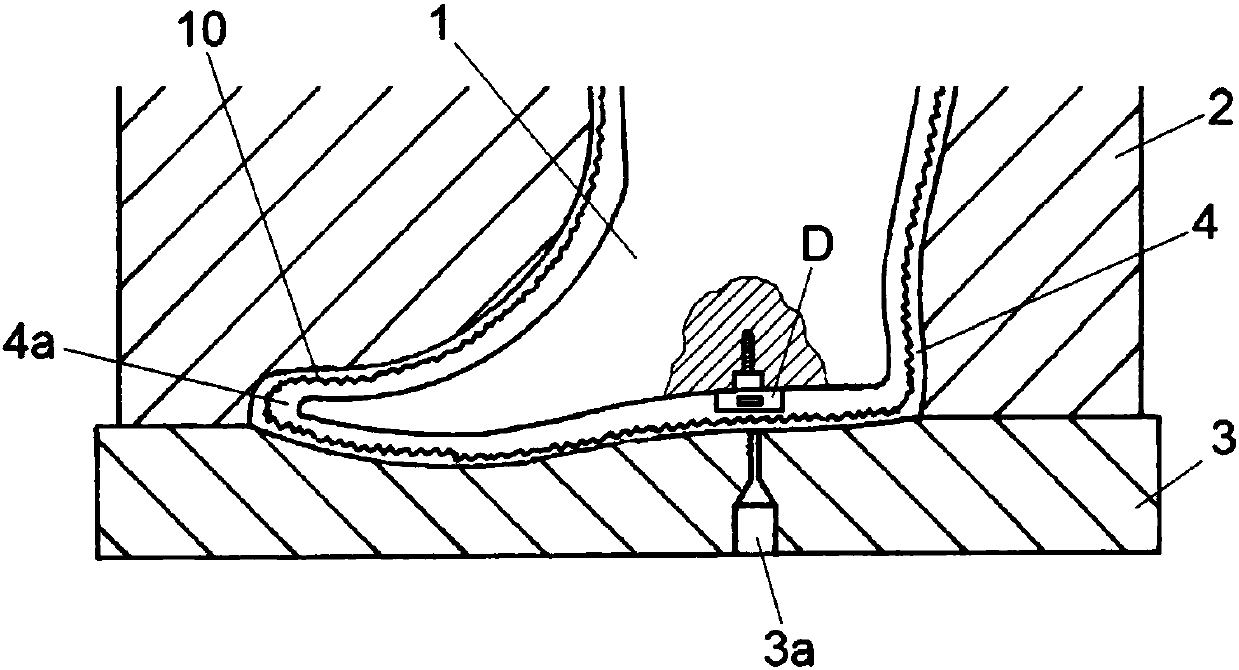

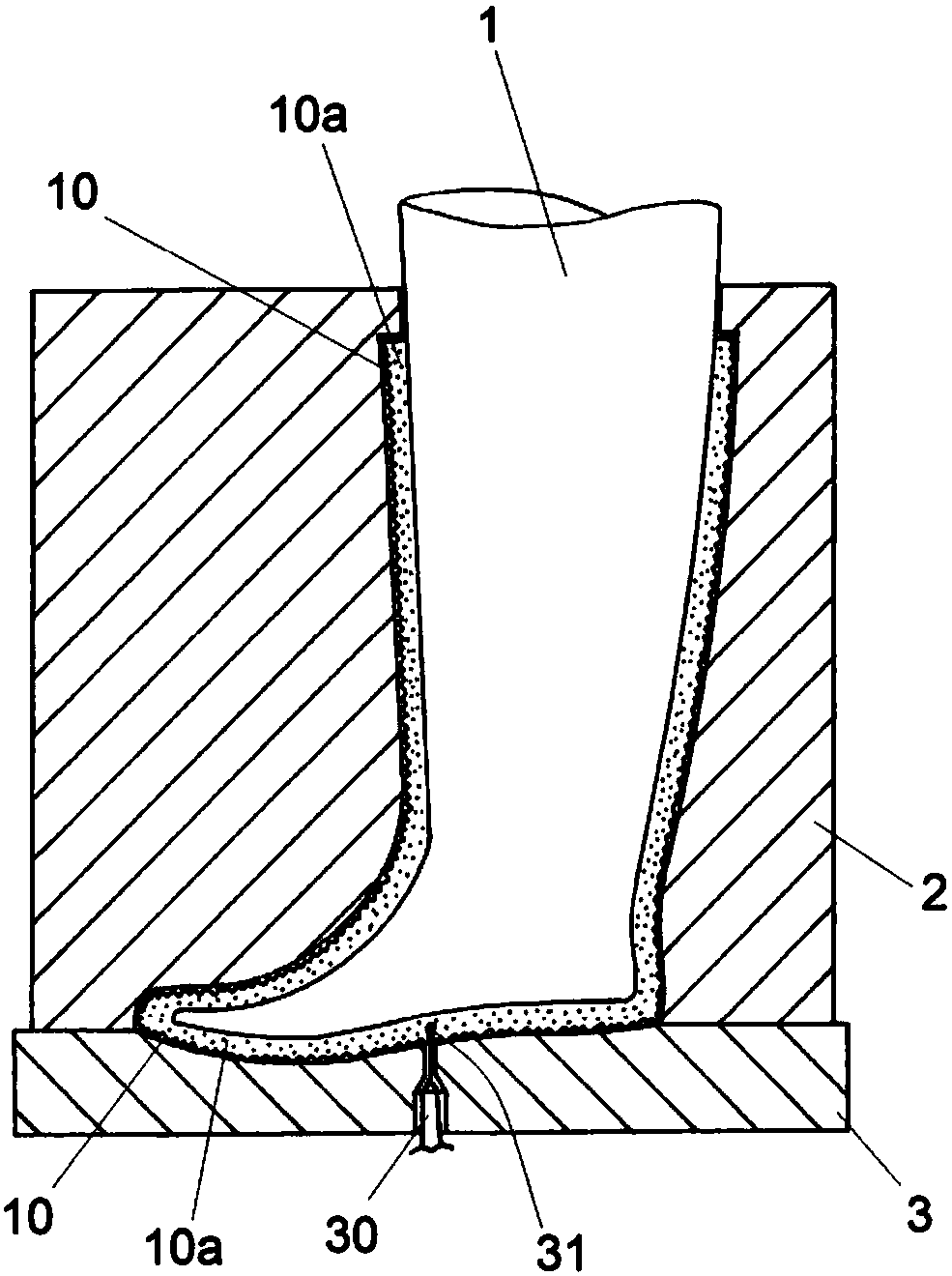

Manufacturing process of shoe with internally waterproofed fabric upper

InactiveCN105291460ANo significant increase in production costsDomestic footwearUpperEngineeringMechanical engineering

A manufacturing process of shoe with fabric upper (10) that is internally provided with a waterproof coating layer (10a) made of plastic material. The process comprises the step of piercing of the upper (10) in order to inject plastic material in an intermediate space (4a) between a core (1) of a mold (S) and the upper (100).

Owner:意大利时尚鞋业有限公司

Modified polyethylene double-wall l corrugated pipe drying agent and preparation method thereof

The invention discloses a preparation method for modified polyethylene double-wall l corrugated pipe drying agent. The preparation method comprises the following steps: an expanded vermiculite processing step, wherein the expanded vermiculite is processed into vermiculite powder of 800-1200 meshes by a jet mill; and the vermiculite powder is added with 1%-10% of oleic acid, 1%-5% of EVA (Ethylene-Ethyl Acetate) resin particles or EVA emulsion and 5%-15% of polyethylene resin particles in percentage by weight; a mixing and heating-up process, wherein the formed mixture is put to a mixer with the speed of 200-260 revolutions / minute for mixing, stirring, fractioning and heating up to 40 DEG C to 60 DEG C; a water-absorbing composite forming step, wherein the mixture is added with 3%-17% of sodium silicate powder in percentage by weight, the mixture added with the sodium silicate powder is put to the mixer with the speed of 200-260 revolutions / minute for stirring and mixing until the temperature is 80 DEG C to 110 DEG C, and then cooled to 40-45 DEG C; and a pelletizing step. The drying agent disclosed by the invention has the advantages that the water absorption capability is strong, the materials are easy to prepare, the price is low, the energy consumption in the process is less, the investment is small, and the operation is simple.

Owner:TIANJIN BAOLISHENGNI PLASTIC PIPE MFG

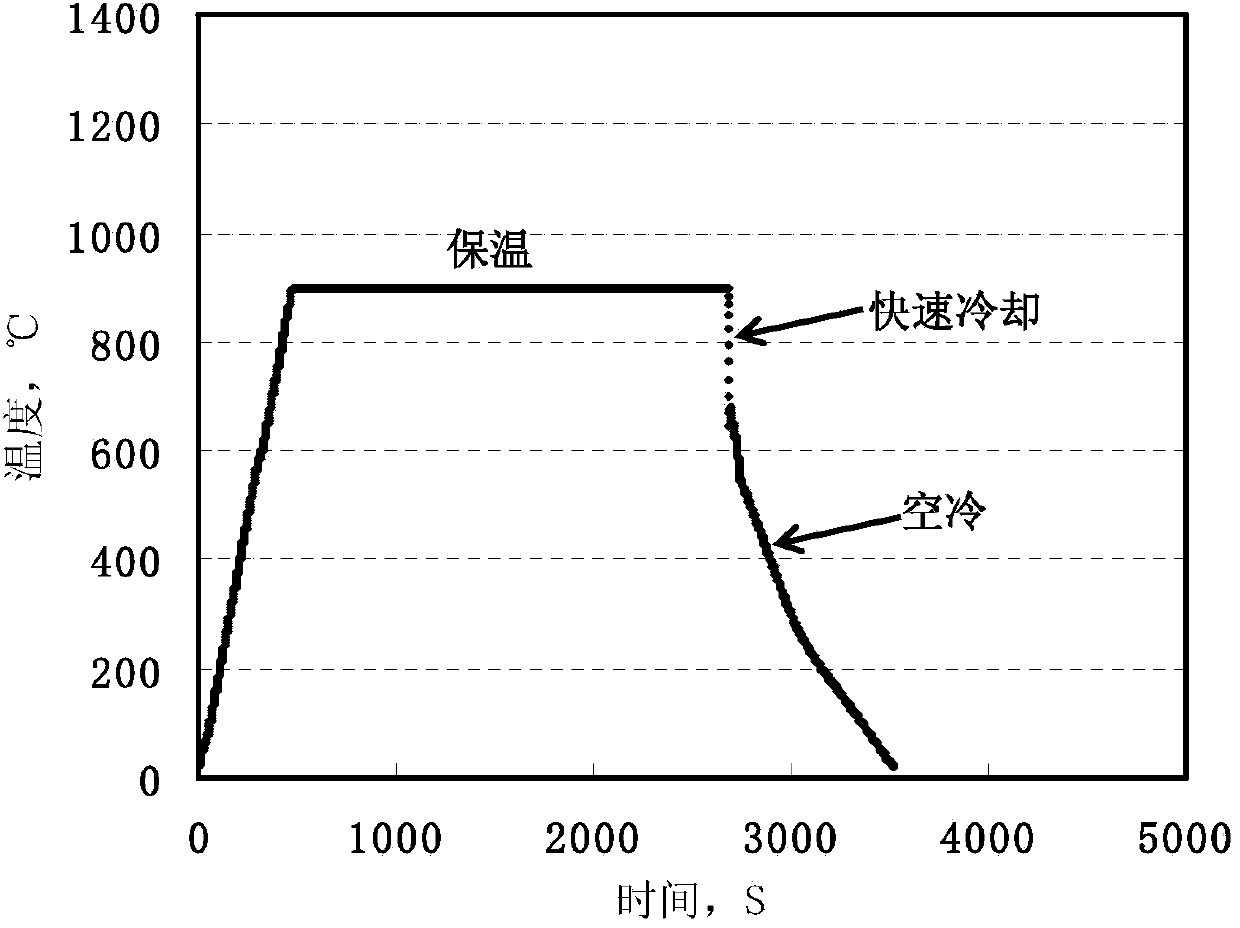

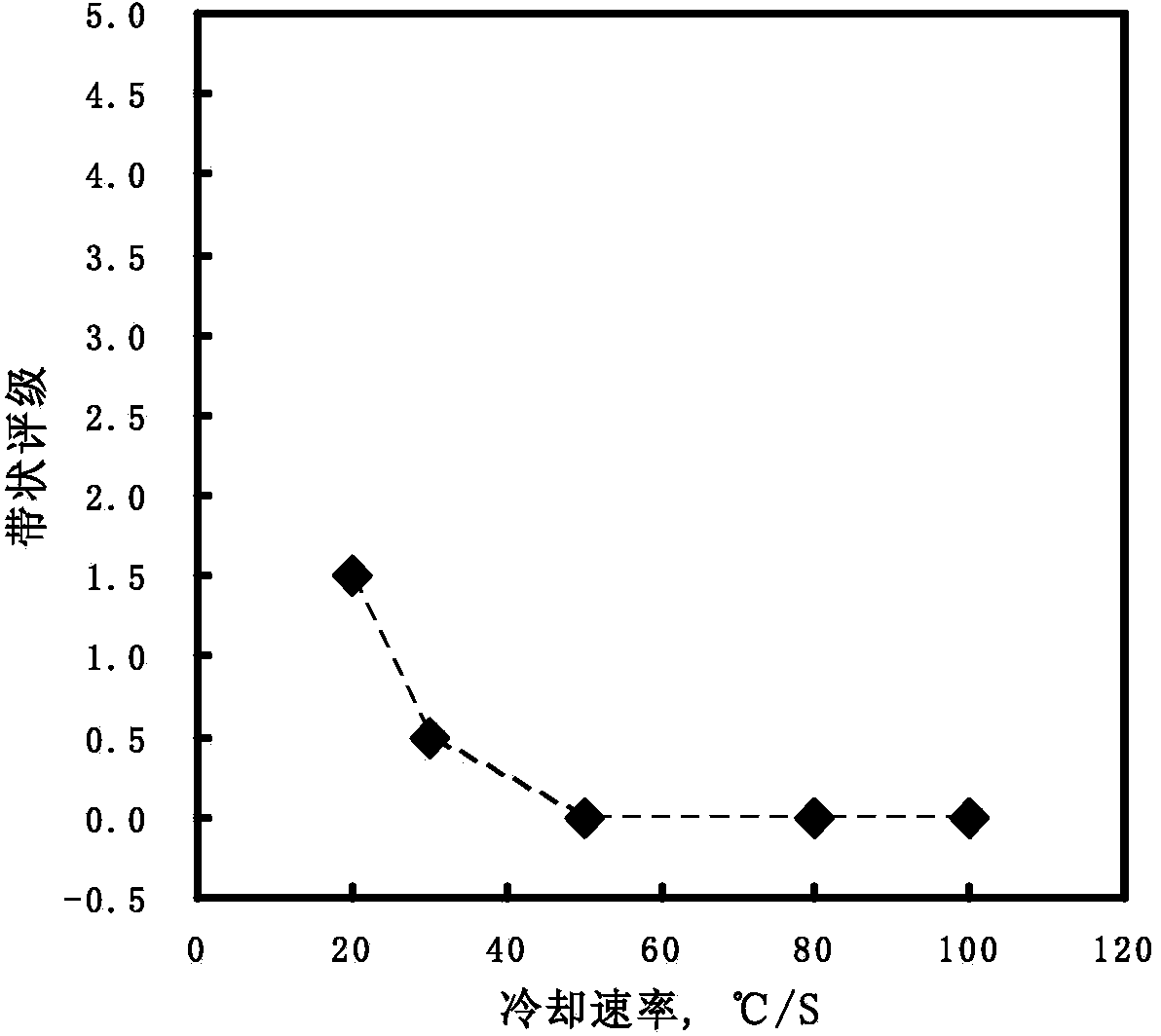

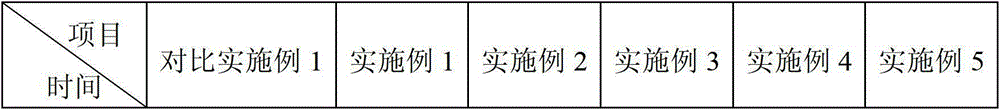

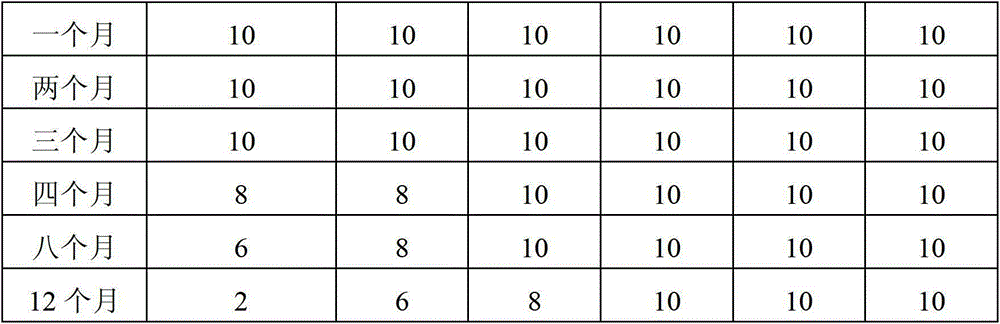

Thermal treatment method for inhibiting and eliminating banded structure in low-alloy and heatproof steel tube

ActiveCN103627871AInhibition or elimination of productionDowngradeQuenching agentsRoom temperatureAlloy

The invention provides a thermal treatment method for inhibiting and eliminating a banded structure in a low-alloy and heatproof steel tube. The method comprises the following steps: sampling low-alloy and heatproof steel tubes which are subjected to smelting and rolling, performing metallographic structure observation and grading the banded structure; machining the low-alloy and heatproof steel tubes which are rolled in a thermal mode to manufacture a cylindrical sample with the diameter of 3mm and the length of 12mm, and welding a K-type thermocouple in a central position along the length direction of the cylindrical sample; heating at a warming speed from the temperature of 20-50 DEG C to 880-910 DEG C and performing heat preservation for 8 minutes to ensure that the cylindrical sample structure is completely austenitized; cooling the cylindrical sample at the cooling speed of 20-100 DEG C / S by jetting nitrogen at a high speed; performing air cooling on the cylindrical sample till reaching the room temperature. The method has the beneficial effects that by using the thermal treatment method, the structure after thermal treatment is a ferrite pearlite, and the banded structure formed in the hot-rolling formation process can be effectively eliminated, and the increase of the production cost is avoided, so that the method is an economic and effective treatment method.

Owner:TIANJIN STEEL PIPE MFG CO LTD

Shaftless Outer Rotor Permanent Magnet Synchronous Motor with Reduced Cogging Effect

ActiveCN103124126BReduce coggingNo significant increase in production costsMagnetic circuit rotating partsSynchronous machine detailsSynchronous motorPermanent magnet synchronous motor

Owner:黑龙江工大华工电机科技有限公司

A modified soybean protein adhesive and its preparation method

ActiveCN103952118BImprove water resistanceNo glue phenomenonProtein adhesivesAldehyde/ketone condensation polymer adhesivesMelamine formaldehyde resinWater resistant

The invention provides a modified soy protein adhesive and a preparation method thereof. A preparation process is as below: (1) adding the defatted soybean flour, water, sodium dodecyl benzene sulfonate and alkali into a reactor, stirring for 5 min, adding ethylene glycol and silicone oil, rising the temperature to 90 DEG C, insulating and stirring for 3 h, cooling, and discharging the materials, so as to obtain a soybean protein pre-hydrolyzed solution; and (2) before usage, adding a homemade or purchased melamine-formaldehyde resin into the soybean protein pre-hydrolyzed solution as a crosslinking agent for the soybean protein, and uniformly mixing at room temperature. The modified soybean protein adhesive by the invention has simple technology, simple and flexible operation and moderate cost. The adhesive has excellent water resistant property, and a prepared poplar glued board test piece has bond strength no less than 0.7 MPa after impregnation in water at (63+ / -3) DEG C for 3 h, shows no glue phenomenon, and has reached the requirements of national standard type II GB / T9846.3-2004 for glued boards.

Owner:SOUTHWEST FORESTRY UNIVERSITY

A kind of power lithium battery pole ear thermal composite molding process

ActiveCN110600667BStable structureNo significant increase in production costsLi-accumulatorsCell component detailsElectrical conductorPhysical chemistry

The invention discloses a power lithium battery tab thermal composite molding process, which specifically includes the following steps: step 1, preparing metal conductor strips; step 2, preparing tab glue; step 3, heating the prepared metal conductor strips, The prepared tab glue is fed to the surface of the heated metal conductor strip for thermocompression bonding, and the heating of the metal conductor strip is stopped after the thermocompression bonding is completed. The tab thermal composite molding process of the power lithium battery of the present invention has a stable tab structure, thermal conductivity, and insulating shoes that exceed similar products on the market, and the production cost does not increase significantly.

Owner:厦门纬达科技股份有限公司

Preparation method of modified polyethylene double-wall l corrugated pipe drying agent

The invention discloses a preparation method for modified polyethylene double-wall l corrugated pipe drying agent. The preparation method comprises the following steps: an expanded vermiculite processing step, wherein the expanded vermiculite is processed into vermiculite powder of 800-1200 meshes by a jet mill; and the vermiculite powder is added with 1%-10% of oleic acid, 1%-5% of EVA (Ethylene-Ethyl Acetate) resin particles or EVA emulsion and 5%-15% of polyethylene resin particles in percentage by weight; a mixing and heating-up process, wherein the formed mixture is put to a mixer with the speed of 200-260 revolutions / minute for mixing, stirring, fractioning and heating up to 40 DEG C to 60 DEG C; a water-absorbing composite forming step, wherein the mixture is added with 3%-17% of sodium silicate powder in percentage by weight, the mixture added with the sodium silicate powder is put to the mixer with the speed of 200-260 revolutions / minute for stirring and mixing until the temperature is 80 DEG C to 110 DEG C, and then cooled to 40-45 DEG C; and a pelletizing step. The drying agent disclosed by the invention has the advantages that the water absorption capability is strong, the materials are easy to prepare, the price is low, the energy consumption in the process is less, the investment is small, and the operation is simple.

Owner:TIANJIN BAOLISHENGNI PLASTIC PIPE MFG

Two-component polyurethane waterproof coating, B component, B component stabilizer and preparation method

ActiveCN103911065BNo significant increase in production costsThe preparation process is stablePolyurea/polyurethane coatingsPolyolToluene diisocyanate

The invention discloses a dual-component polyurethane waterproof paint, a B component, a B component stabilizing agent and a preparation method. The preparation method of the B component stabilizing agent of the dual-component polyurethane waterproof paint comprises the following steps: 1)mixing 30-35% of polyether glycol, 16-20% of plasticizer and 5.0-7.0% of toluene diisocyanate and reacting to obtain a material liquid A; and 2)mixing the material liquid A, 0.01-0.02% of catalyst and 40-45% of diluent, reacting until the NCO% content is 1.0-1.05% to obtain the product. The B component stabilizing agent can greatly improve the stability of the B component, deposition generation can be effectively reduced, and the expiration date of the paint is prolonged. The B component enables long-term stabilization and storage under high temperature and low temperature. The cost production of the dual-component polyurethane waterproof paint is not obviously increased, and the product comprehensive property is high. The preparation method of the invention has the advantages of stable technology, easy realization of industrial production, low cost and environmental protection.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Thermal treatment method for inhibiting and eliminating banded structure in low-alloy and heatproof steel tube

ActiveCN103627871BInhibition or elimination of productionDowngradeQuenching agentsRoom temperatureNitrogen

The invention provides a thermal treatment method for inhibiting and eliminating a banded structure in a low-alloy and heatproof steel tube. The method comprises the following steps: sampling low-alloy and heatproof steel tubes which are subjected to smelting and rolling, performing metallographic structure observation and grading the banded structure; machining the low-alloy and heatproof steel tubes which are rolled in a thermal mode to manufacture a cylindrical sample with the diameter of 3mm and the length of 12mm, and welding a K-type thermocouple in a central position along the length direction of the cylindrical sample; heating at a warming speed from the temperature of 20-50 DEG C to 880-910 DEG C and performing heat preservation for 8 minutes to ensure that the cylindrical sample structure is completely austenitized; cooling the cylindrical sample at the cooling speed of 20-100 DEG C / S by jetting nitrogen at a high speed; performing air cooling on the cylindrical sample till reaching the room temperature. The method has the beneficial effects that by using the thermal treatment method, the structure after thermal treatment is a ferrite pearlite, and the banded structure formed in the hot-rolling formation process can be effectively eliminated, and the increase of the production cost is avoided, so that the method is an economic and effective treatment method.

Owner:TIANJIN STEEL PIPE MFG CO LTD

A kind of ceramic green body reinforcing agent, its preparation method and application

The invention discloses a ceramic body reinforcing agent, which comprises the following ingredients in parts by weight: 3-15 parts of carboxymethyl cellulose, 13-25 parts of sodium tripolyphosphate, 4-12 parts of sodium silicate, and 5-20 parts of bentonite 40-73 parts and wollastonite. The ceramic body strengthening agent of the present invention can significantly improve the wet body strength of the ceramic body with high content of barren materials; it can be ball milled together with the ceramic green body raw materials, so that the raw materials can be fully mixed evenly, thereby ensuring the uniformity of the wet body strength ; and the raw materials are easy to obtain, low in cost, and environmentally friendly, and do not significantly increase the production cost of ceramic products. At the same time, its addition and use process is very simple, and industrial production can be realized. At the same time, the invention also provides a preparation method and application of the ceramic body reinforcing agent.

Owner:清远市简一陶瓷有限公司 +1

A method for promoting the accumulation of carotenoids and β-carotene in Dunaliella by utilizing β-ionone

ActiveCN108949888BSimple cultivation conditionsStrong stress resistanceMicroorganism based processesFermentationMicroorganismIonone

The invention belongs to the technical field of food science and discloses a method for promoting Dunaliella to accumulate carotenoids and β-carotene by using β-ionone. The method: the Dunaliella cells to be induced are induced and cultured in a medium containing β-ionone, the carotenoids and the β-carotene in the carotenoids are accumulated in the algae cells, and then the pigment is extracted; The induced Dunaliella cells are Dunaliella cells in logarithmic growth phase and / or stationary phase. The invention is simple, easy to implement, low in cost, can significantly increase the output of total carotenoids and β-carotene, and Dunaliella is extremely salt-tolerant single-celled green algae with simple culture conditions and is not easy to be polluted by other microorganisms, which is beneficial to Large-scale breeding meets the standards of industrialized large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

Method of making shoe with inner waterproof fabric upper

InactiveCN105291460BNo significant increase in production costsDomestic footwearUpperPlastic materialsEngineering

A method of manufacturing a shoe having an inner waterproof textile upper (10) with a waterproof covering layer (10a) made of plastic material inside. The method comprises the step of piercing the upper (10) to inject plastic material into the intermediate space (4a) between the core (1) and the upper (10) of the mold (S).

Owner:意大利时尚鞋业有限公司

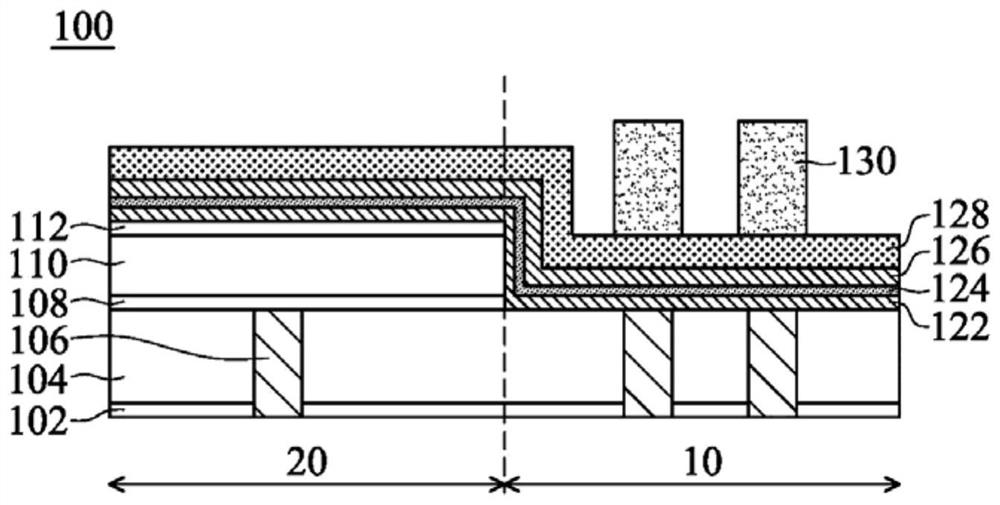

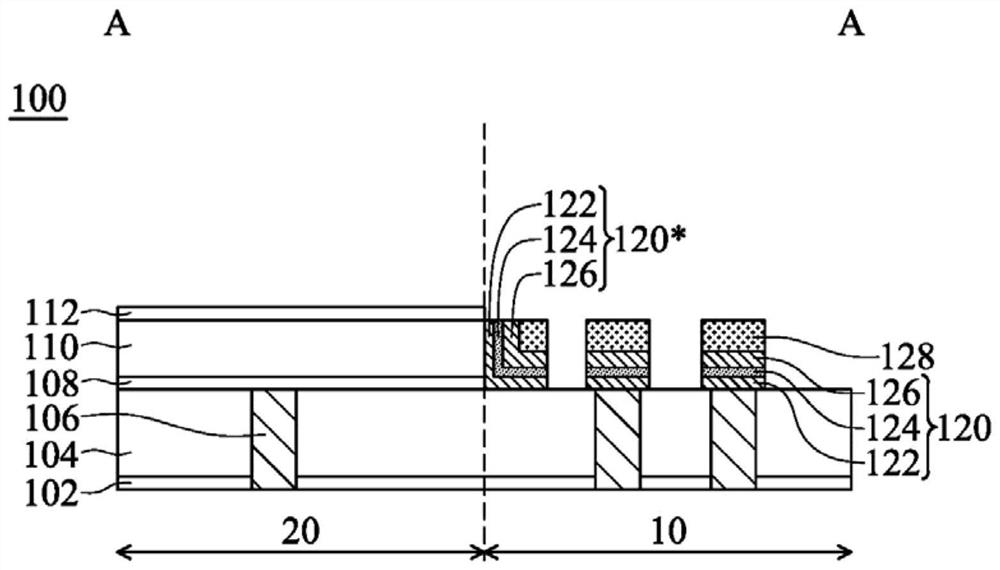

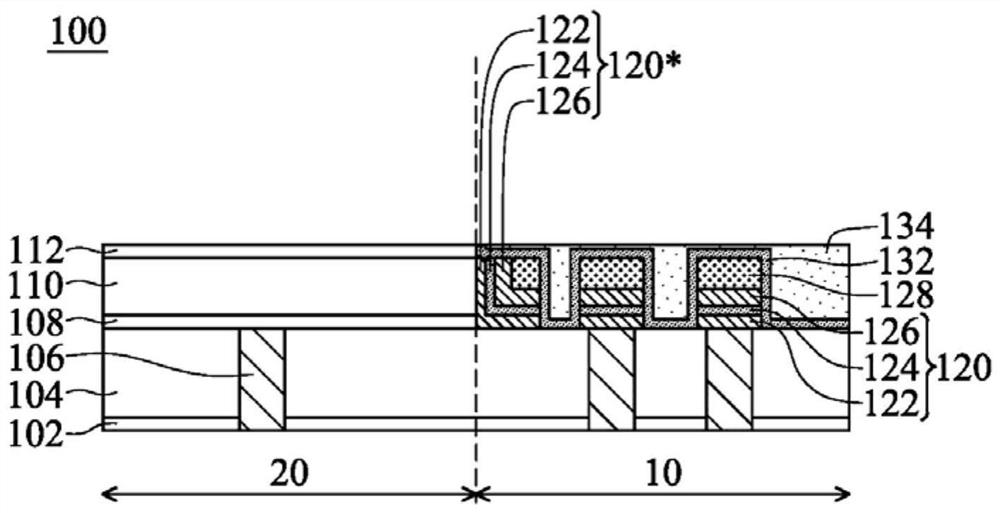

Resistive random access memory structure and manufacturing method thereof

PendingCN112531107AAvoid it happening againDoes not significantly increase complexityElectrical apparatusMemory cellDielectric permittivity

The present invention provides a resistive random access memory structure and a manufacturing method thereof. The resistive random access memory structure comprises: a substrate having an array regionand a peripheral region; a first low-dielectric-constant dielectric layer, which is located in the peripheral area and has a dielectric constant of smaller than 3; a plurality of memory cells, whichare positioned on the substrate and are positioned in the array region; a gap filling dielectric layer, which is located in the array region, covers the memory cells and fills in space between the adjacent memory cells; a plurality of first conductive plugs, which are located in the gap filling dielectric layer, wherein each of the first conductive plugs is in contact with one of the memory cells;and a dummy memory unit, which is located at the junction of the array region and the peripheral region and is not in contact with any one of the first conductive plugs. According to the resistive random access memory structure provided by the invention, the yield and the reliability of a product can be obviously improved, and process complexity, production cost and production time are reduced.

Owner:WINBOND ELECTRONICS CORP

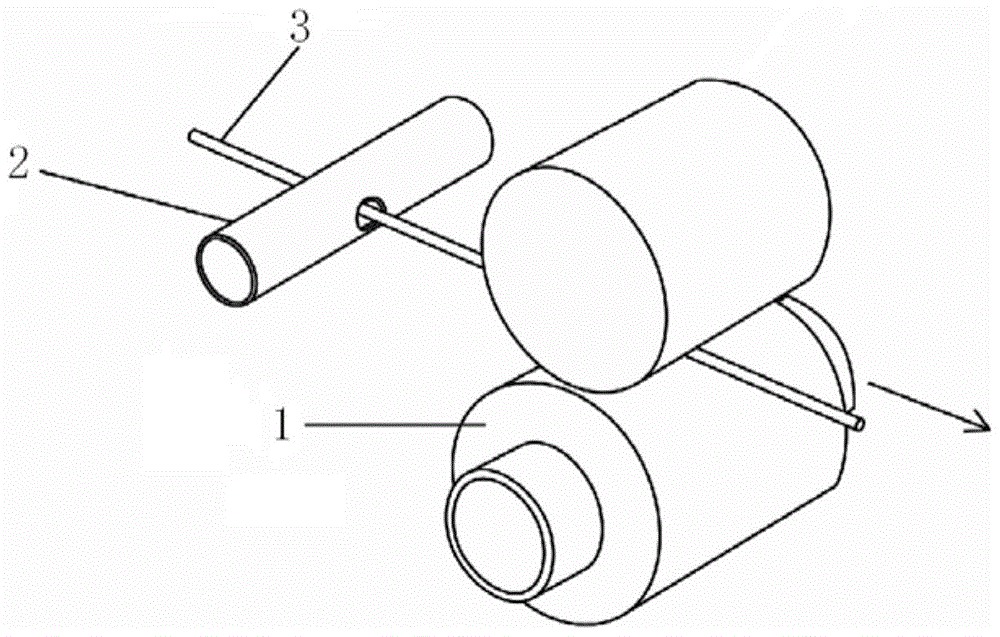

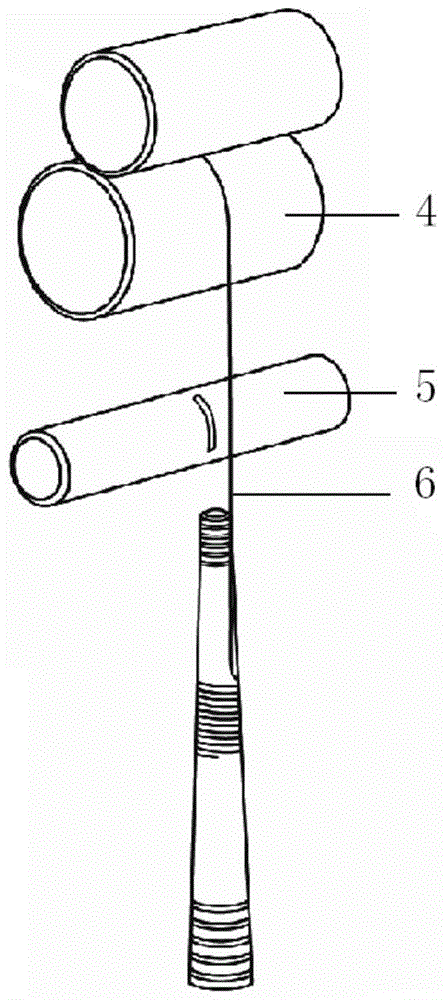

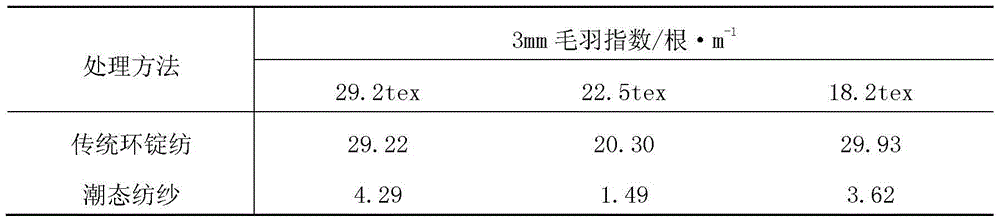

A kind of short fiber spinning method

The invention relates to a short fiber spinning method which comprises a cotton blending process, a coiling process, a slivering process, a drawing process, a combing process, a roving process and a fine yarn spinning process. The short fiber spinning method is characterized by further comprising a maintenance process positioned between the roving process and the fine yarn spinning process, wherein the maintenance process means that rough yarns obtained by the roving process are put in an airtight space, and steam is injected into the airtight space to improve moisture content of fibers in the rough yarns and moisture content of capillaries among the fibers. By means of the short fiber spinning method, the maintenance process is added between the roving process and the fine yarn spinning process, and the rough yarns are wetted preliminarily before further processing. In the yarn spinning process, the rough yarns are kept to be wet in the whole process of processing the rough yarns into fine yarns by means of a spraying device arranged on a fine yarn machine. Therefore, the moisture content in different stages of short fiber spinning is increased, internal stress among fiber aggregation in different stages of spinning is eliminated, cohesive force among the fibers is increased, and quality indexes of the yarns are increased. The short fiber spinning method can be widely applied to the short fiber spinning process.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

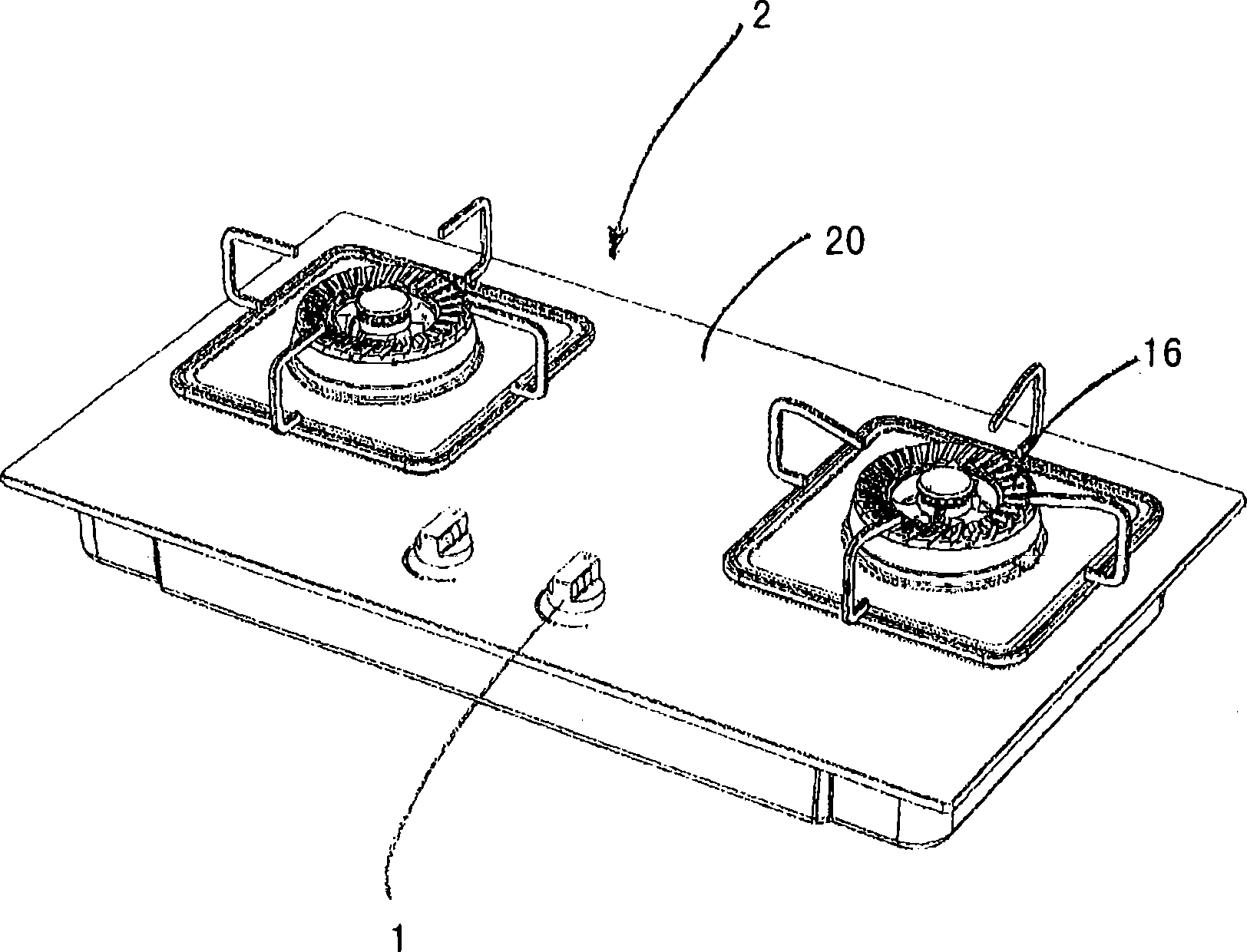

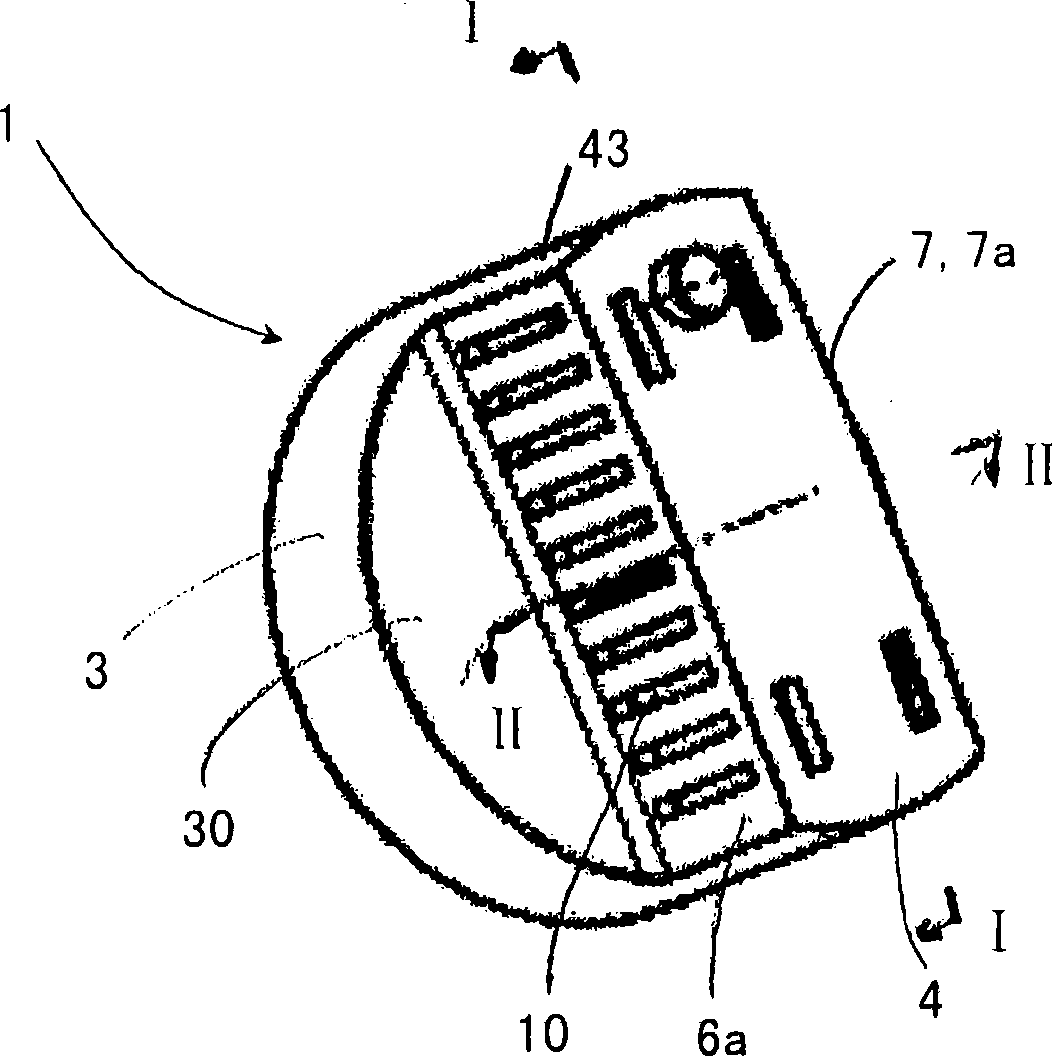

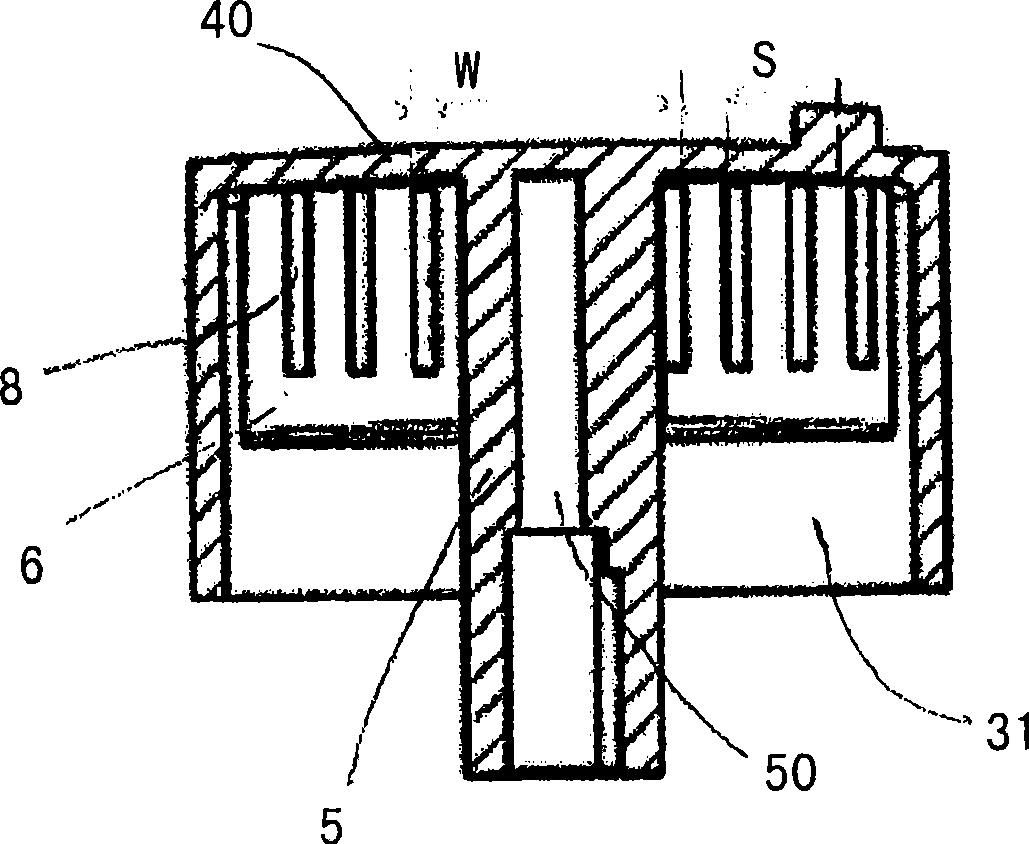

Control knob for cooling tool and cooking tool with the same

InactiveCN101509674AReduce the effective contact areaEasy to operateDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com