Ceramic green body reinforcing agent as well as preparation method and application thereof

A ceramic green body and reinforcing agent technology, which is applied in the field of ceramic green body reinforcing agents, can solve the problems of low ceramic green body strength, affecting production efficiency, wet green body cracking, etc., achieve low cost, increase production cost, and improve wet green body strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

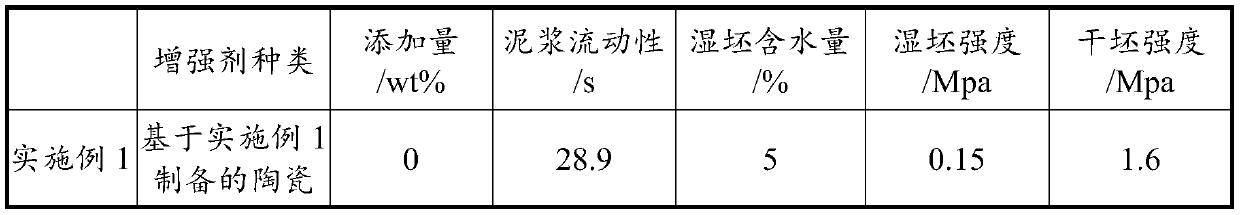

Examples

Embodiment Construction

[0020] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples.

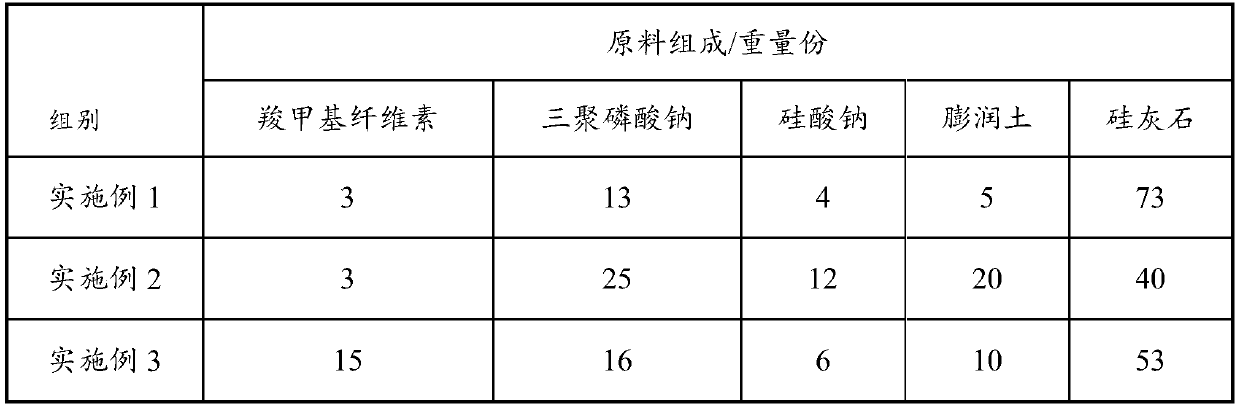

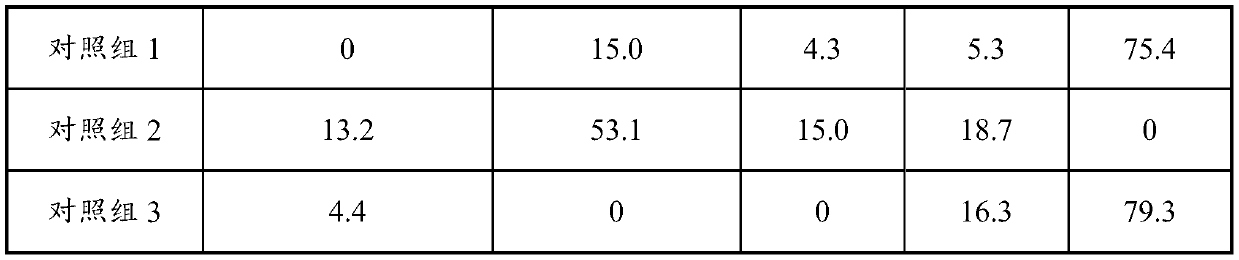

[0021] The present invention sets embodiment 1~3 and control group 1~3, and the weight parts of each component in specific embodiment 1~3 and control group 1~3 are as shown in table 1, and wherein, bentonite is purchased as for Foshan Boer Ceramic Technology Co., Ltd. Company, chemical composition: SiO 2 62.44~66.58%, Al 2 o 3 18.32~19.88%, Fe 2 o 3 2.79~3.56%, CaO 0.36~0.48%, MgO1.99~2.46%, K 2 O 0.99~1.43%, Na 2 O 1.22~1.77%, TiO 2 0.07~0.12%, the loss on ignition rate is 4.95~6.12%; wollastonite was purchased from Foshan Sanshui Baoligao Inorganic Materials Co., Ltd., and its chemical composition is: SiO 2 49.21~52.11%, Al 2 o 3 0.19~0.29%, Fe 2 o 3 0.13~0.19%, CaO 40.67~45.88%, MgO 1.22~1.55%, K 2 O 0.02~0.04%, Na 2 O 0.03~0.05%; loss on ignition rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com