Vacuum garbage bag

A garbage bag and vacuum technology, applied in the field of hazardous waste, can solve problems such as high cost, complex bag body, and limited application fields, and achieve the effect of anaerobic packaging and increase production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

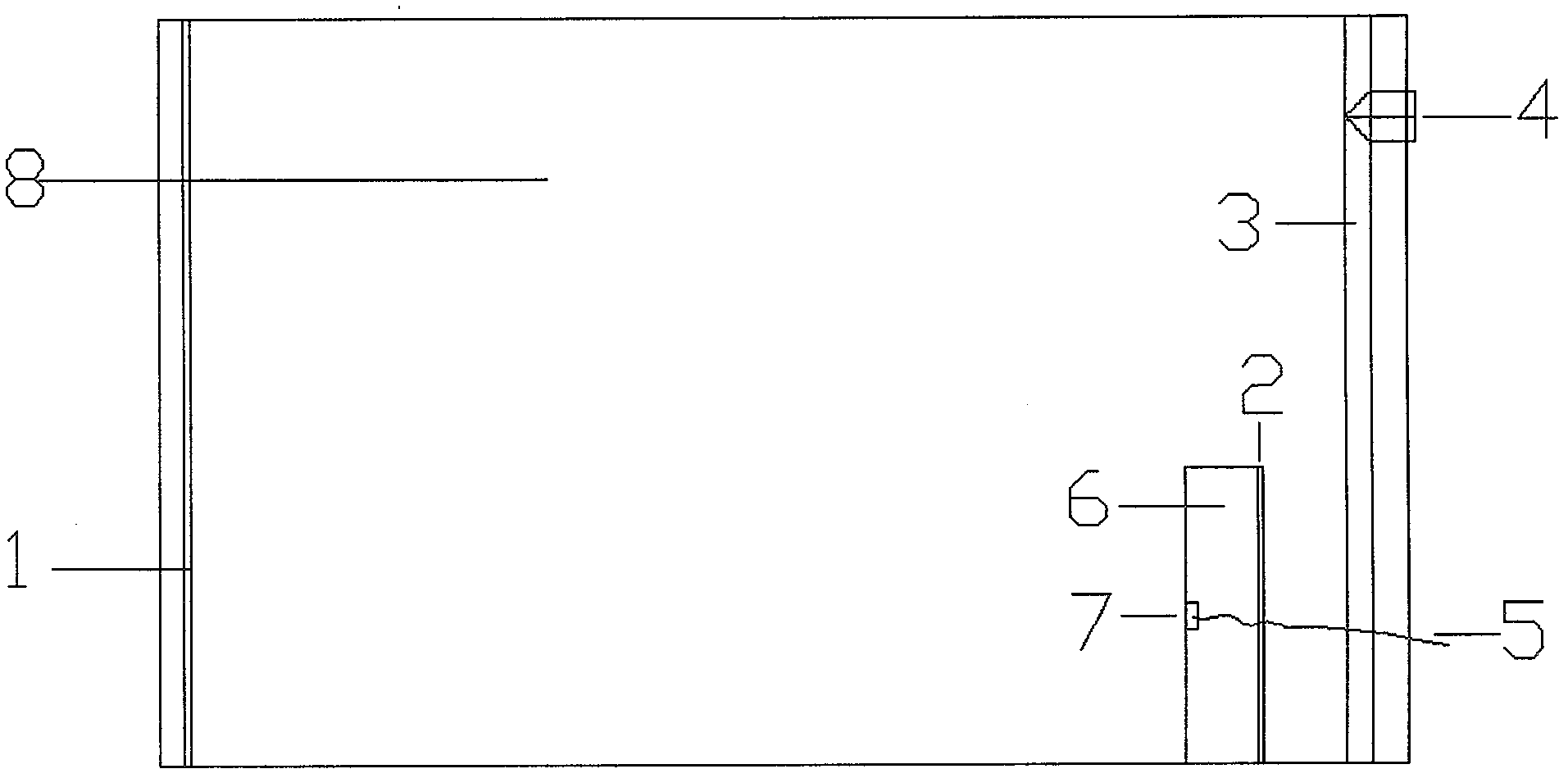

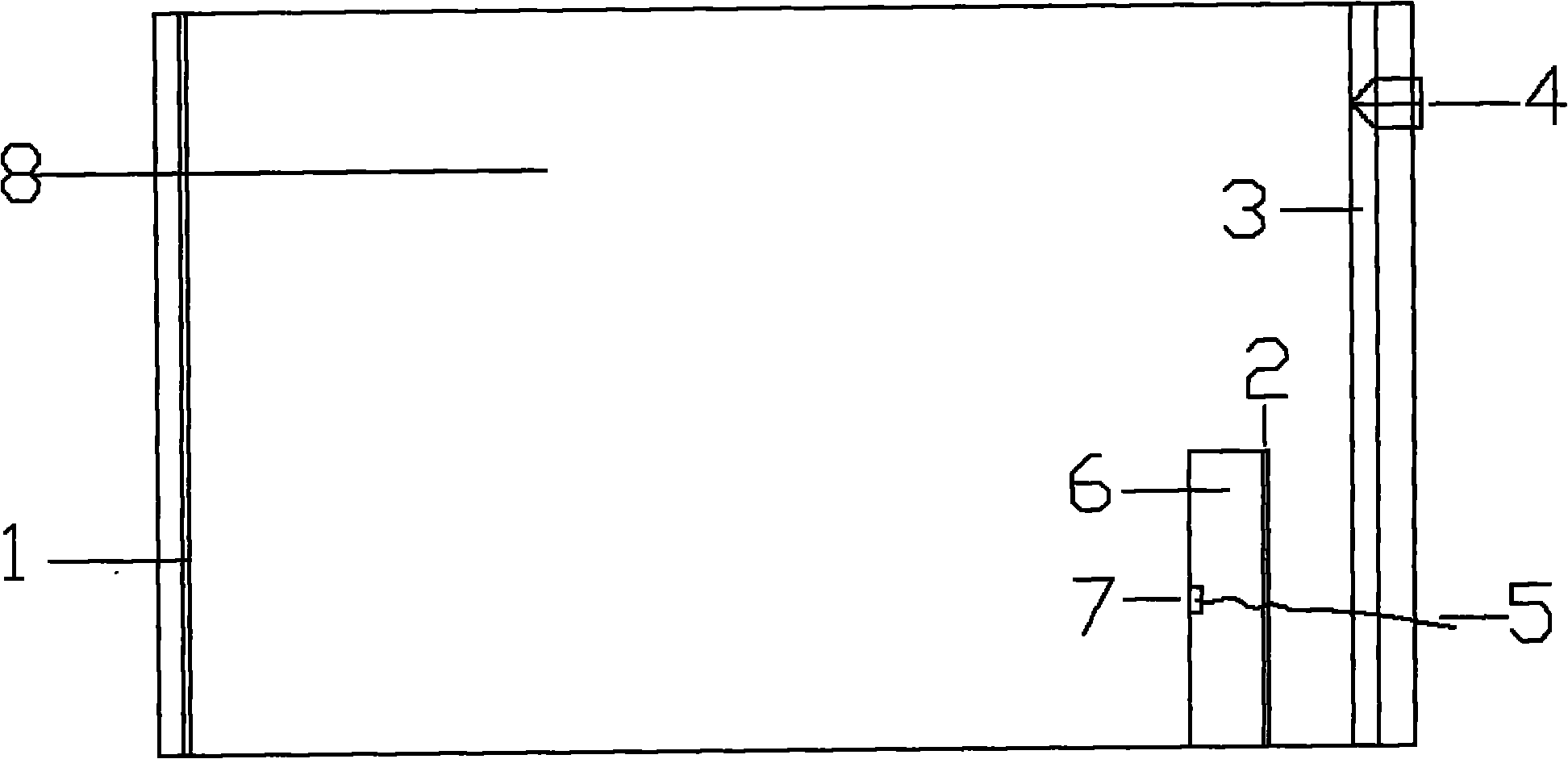

[0007] This patent mainly consists of the following eight parts:

[0008] 1. Thermoplastic bottom edge (sealing the barrel-shaped ordinary plastic bag with a thermoplastic sealing machine to form the bag body 8)

[0009] 2. The connecting strip of the check valve 6 and the bag body 8 (made of thermoplastic sealing or bonding)

[0010] 3. Adhesive strip (this is a double-sided adhesive strip folded into a ring)

[0011] 4. Reserve the covering layer of the adhesive strip 3 (the covering layer is a part longer than the actual adhesive strip, so that the covering layer of the adhesive strip 3 can be easily uncovered, so that the upper and lower layers of the bag body 8 are tightly combined)

[0012] 5. The non-return valve turning up rope (used to turn up the non-return valve to ensure the smooth progress of the vacuum suction process and the smooth completion of the vacuum suction operation, and to ensure that no gas flows into the bag before the glue sticks together8 )

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com