Method for preparing high-strength and high-isolation condoms from modified graphene/latex composite material

A composite material, graphene technology, applied in the direction of male contraceptives, coatings, etc., can solve the problems of easy falling off and breakage, poor elasticity, high cost, increase comfort, reduce and inhibit the transmission probability of viruses and microorganisms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

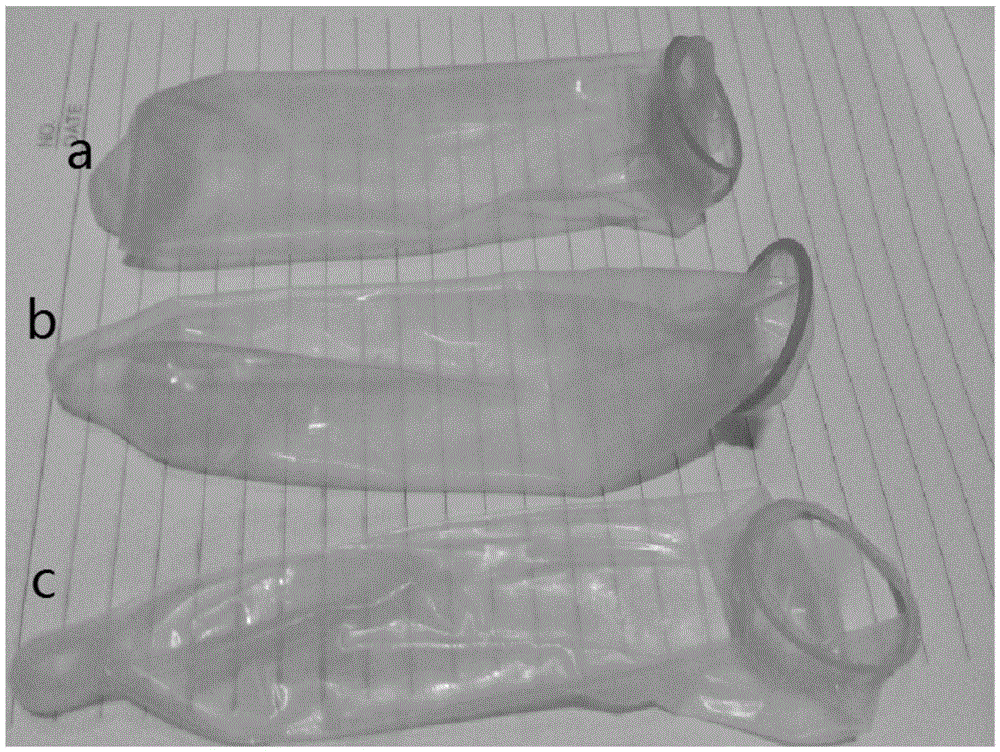

[0061] Adding 200Kg concentration in a clean mixing tank is the natural rubber latex of 60wt%, gradually adding 200Kg concentration under stirring conditions is the graphene aqueous solution after the sulfonation of 0.5wt‰, after adding, then add dispersion stabilizer (such as : sodium lauricate or F108), make the dispersion stabilizer account for about 1wt% to 2wt%, and keep stirring for 1 hour to make it evenly mixed. At this time, adjust the viscosity to about 15 mPa·s. Let the compounded glue stand for about 24 hours to fully mature, then add it to the dipping machine for two dips, and then process and produce it, and finally pass the performance test to get the finished product.

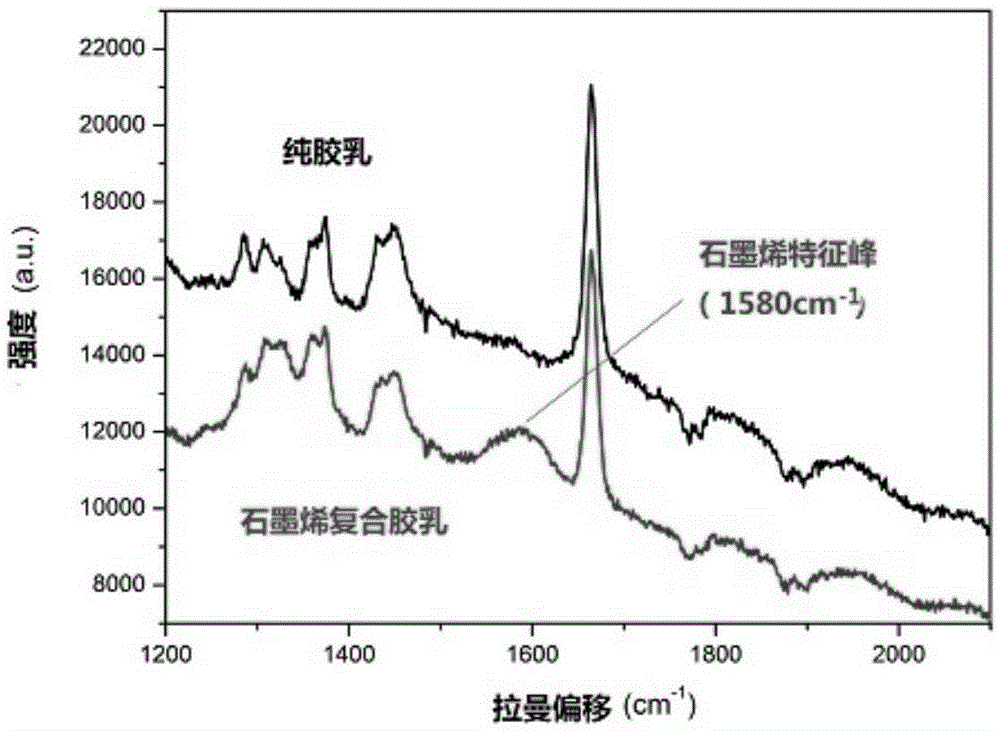

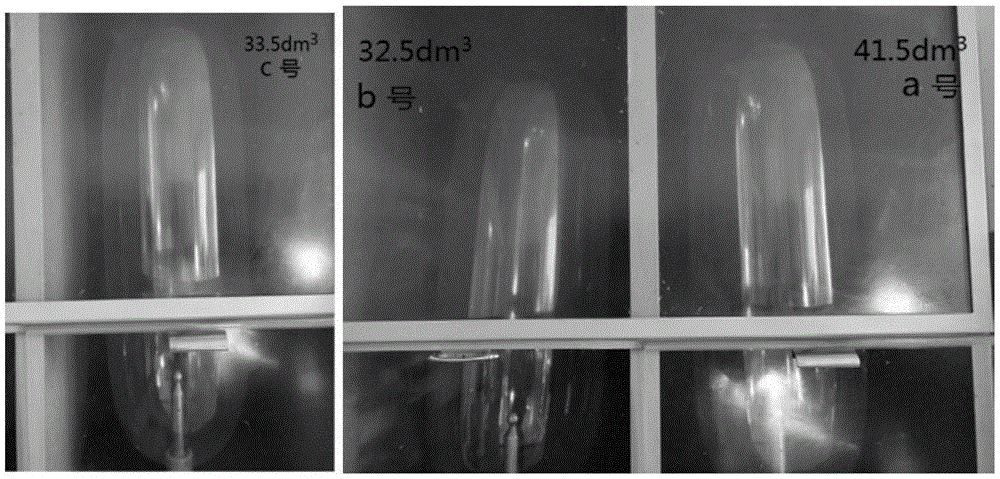

[0062] In order to verify the performance advantages of the new material prepared by the present invention and the condom product, the inventor prepared the batch of graphene / latex prepared in Example 1 according to the national standard GB7544-2009 "Natural Latex Rubber Condom Technical Require...

Embodiment 2

[0073] Adding 200Kg concentration in a clean mixing tank is the natural rubber latex of 35wt%, gradually adding 200Kg concentration under stirring conditions is the graphene aqueous solution after amination of 0.05wt‰, after adding, then add dispersion stabilizer (such as: Sodium lauricate or F108), the dispersion stabilizer accounts for about 0.5wt% to 1wt%, and the stirring is continued for 1 hour to make it evenly mixed, and the viscosity is about 8mPa·s. Let the compounded glue stand for about 24 hours to fully mature, then add it to the dipping machine for three times of dipping, then process and produce, and finally pass the performance test to get the finished product.

Embodiment 3

[0075] Adding 200Kg concentration in a clean mixing tank is the natural rubber latex of 60wt%, gradually adding 200Kg concentration under stirring conditions is the graphene aqueous solution after the carboxylation of 1wt‰, after adding, then add dispersion stabilizer (such as: Sodium silicate or F108), the dispersion stabilizer accounts for about 1wt% to 2wt%, and the stirring is continued for 1 hour to make it evenly mixed, and the viscosity is about 15mPa·s. Let the compounded glue stand for about 24 hours to fully mature, then add it to the dipping machine for two dips, and then process and produce it, and finally pass the performance test to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com