Manufacturing process of shoe with internally waterproofed fabric upper

A production method and technology of shoe uppers, which are applied in the direction of shoemaking machinery, shoe uppers, footwear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

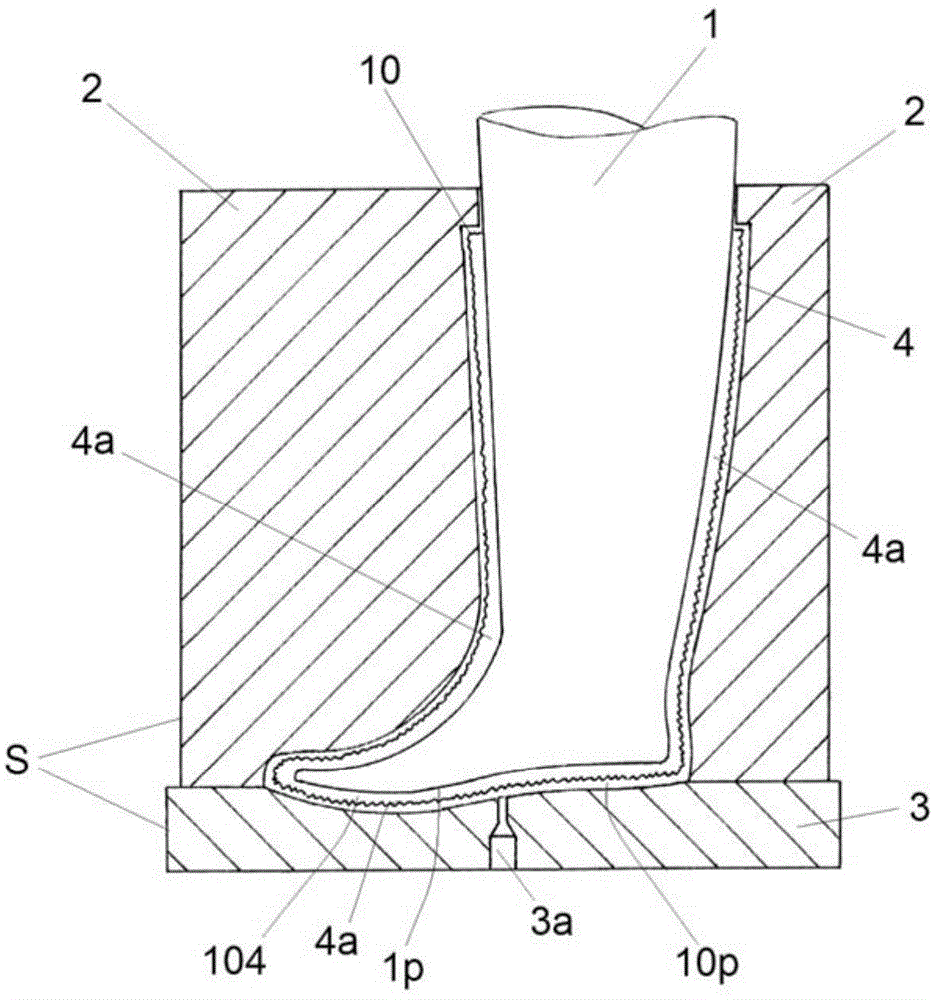

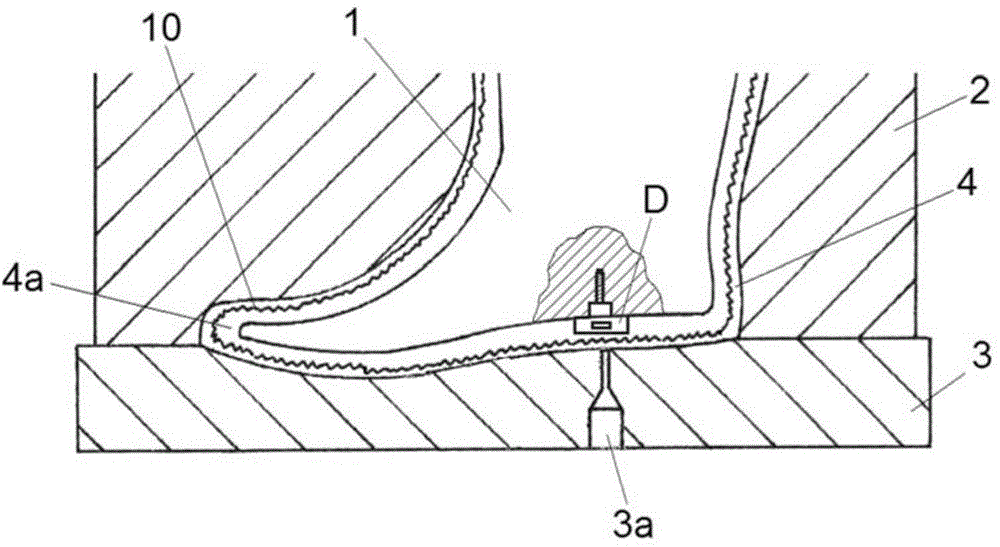

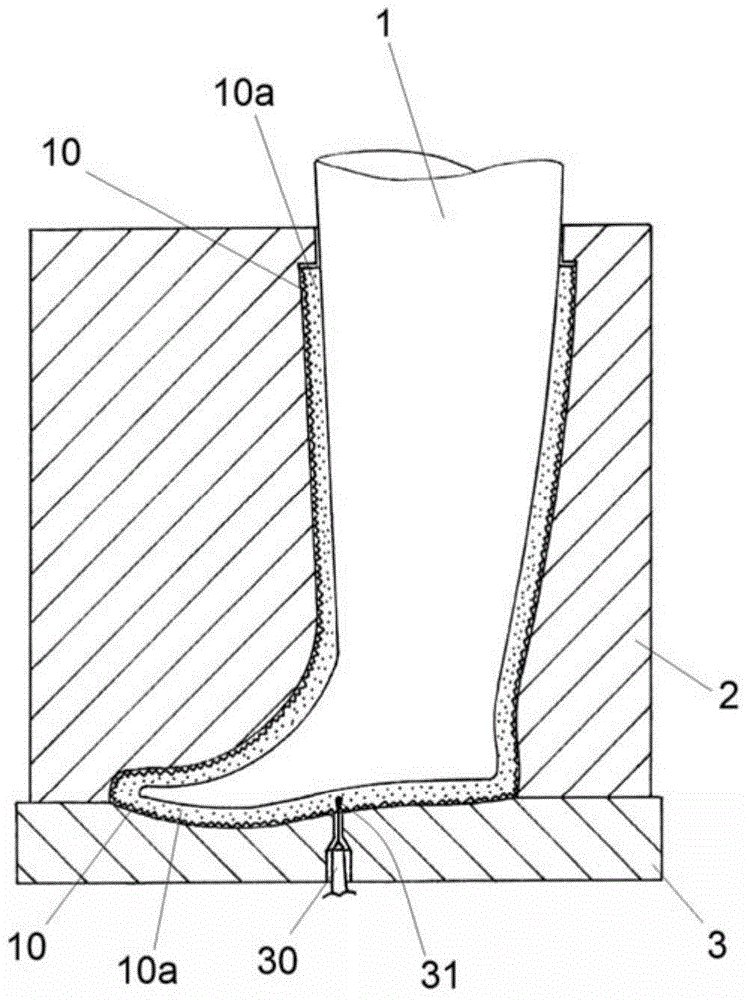

[0024] refer to figure 1 , the method of the present invention uses a mold S consisting of three parts.

[0025] The first part is the core 1, which replicates the shape of the user's leg and foot. The core 1 comprises a bottom 1 p which replicates the sole of a foot. The upper 10 is made of fabric and will fit on the outside of the core. The upper 10 has a substantially sock shape and has a bottom 10p disposed below the bottom 1p of the mandrel.

[0026] The second part is the die 2 of the mold S, which consists of two half-shells. The die 2 is adapted to surround the core 1 to create a lateral gap 4 between the core 1 and the die 2 .

[0027] The third part is the cover 3 of the mold S, adapted to close the die 2 substantially at the level of the bottom 1 p of said core 1 to create a lower gap 104 between the bottom 1 p of the core 1 and the cover 3 . The lower gap 104 communicates with the lateral gap 4 . In this way, a gap 4 , 104 enclosing the core 1 laterally and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com