Sample part with adjustable gas-leakage quantity and detection method thereof

A technology of gas leakage and leakage, which is applied in fluid tightness testing, machine/structural component testing, liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problems of non-adjustable leakage and large leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

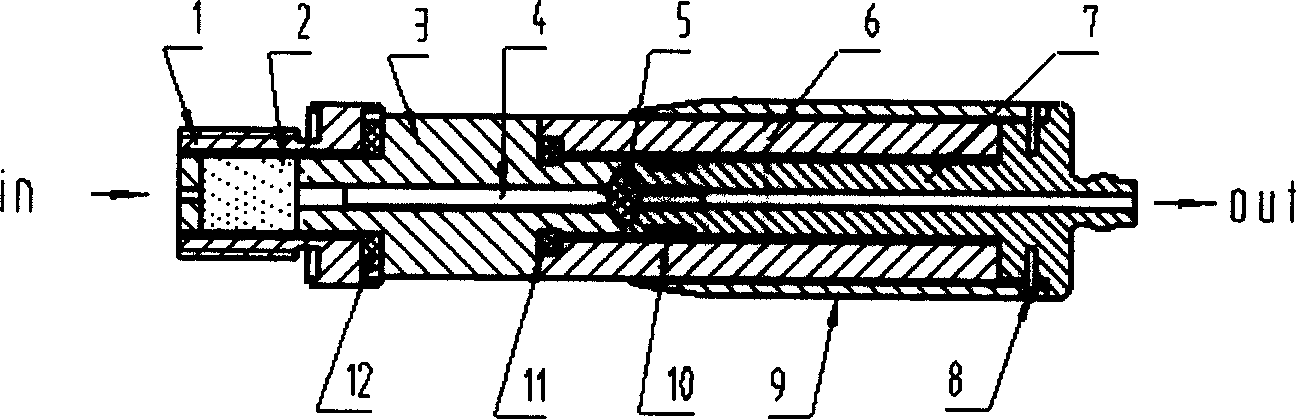

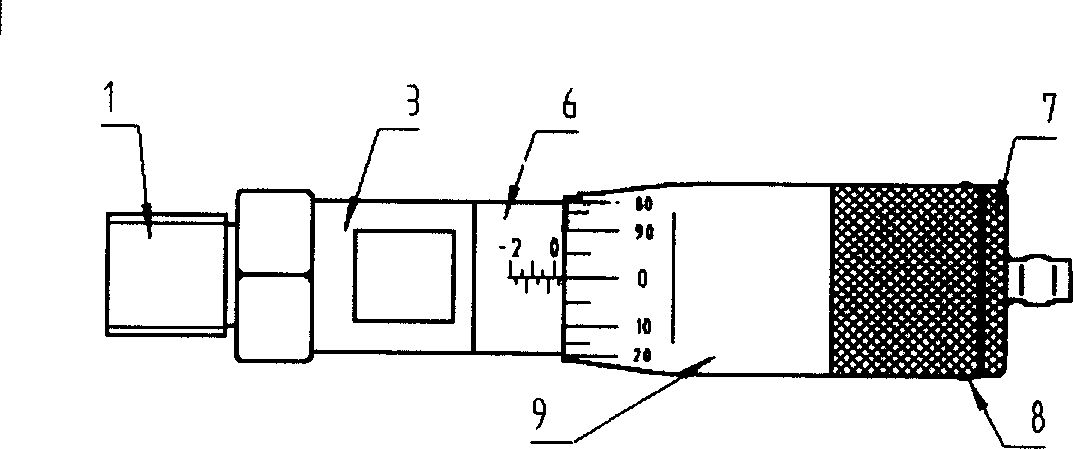

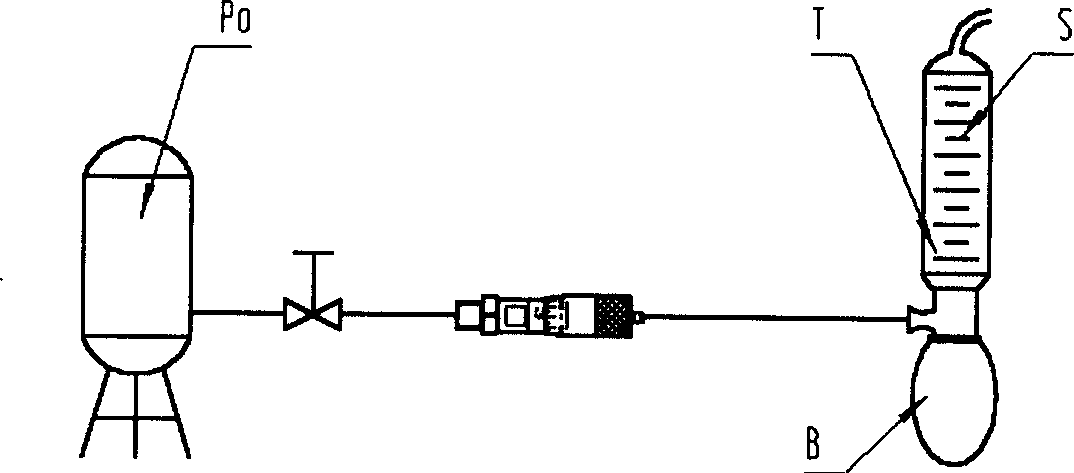

[0043] Combine below figure 1 , figure 2 and image 3 The present invention is described further:

[0044] exist figure 1 Middle: The gas leakage adjustable sample includes: inlet nozzle 1, filter element 2, plug sleeve 3, plug rod 4, leakage core 5, internal thread of the main ruler 6, external thread of the gas outlet nozzle 7, fixed pin 8, auxiliary ruler cylinder 9. Live sealing ring 10, small sealing ring 11, large sealing ring 12, wherein:

[0045] Put the filter element 2 into the intake nozzle 1 to form an air filter.

[0046] The plug sleeve 3 is screwed into the gas connection nozzle 1 by threads, and a large sealing ring 12 is added. The left end of the plug sleeve 3 is limited to the filter element 2.

[0047] The high-pressure air flow flowing through the filter element 2 flows towards the leakage core 5 through the micron-level gap between the plug sleeve 3 and the plug rod 4, and the length of the gap is inversely proportional to the leakage amount.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com