Roller grinding mill and method for grinding materials that contain magnetizable components

A tumbler and grinding technology, applied in grain processing, grain pod removal, grain hulling, etc., to achieve the effect of low frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

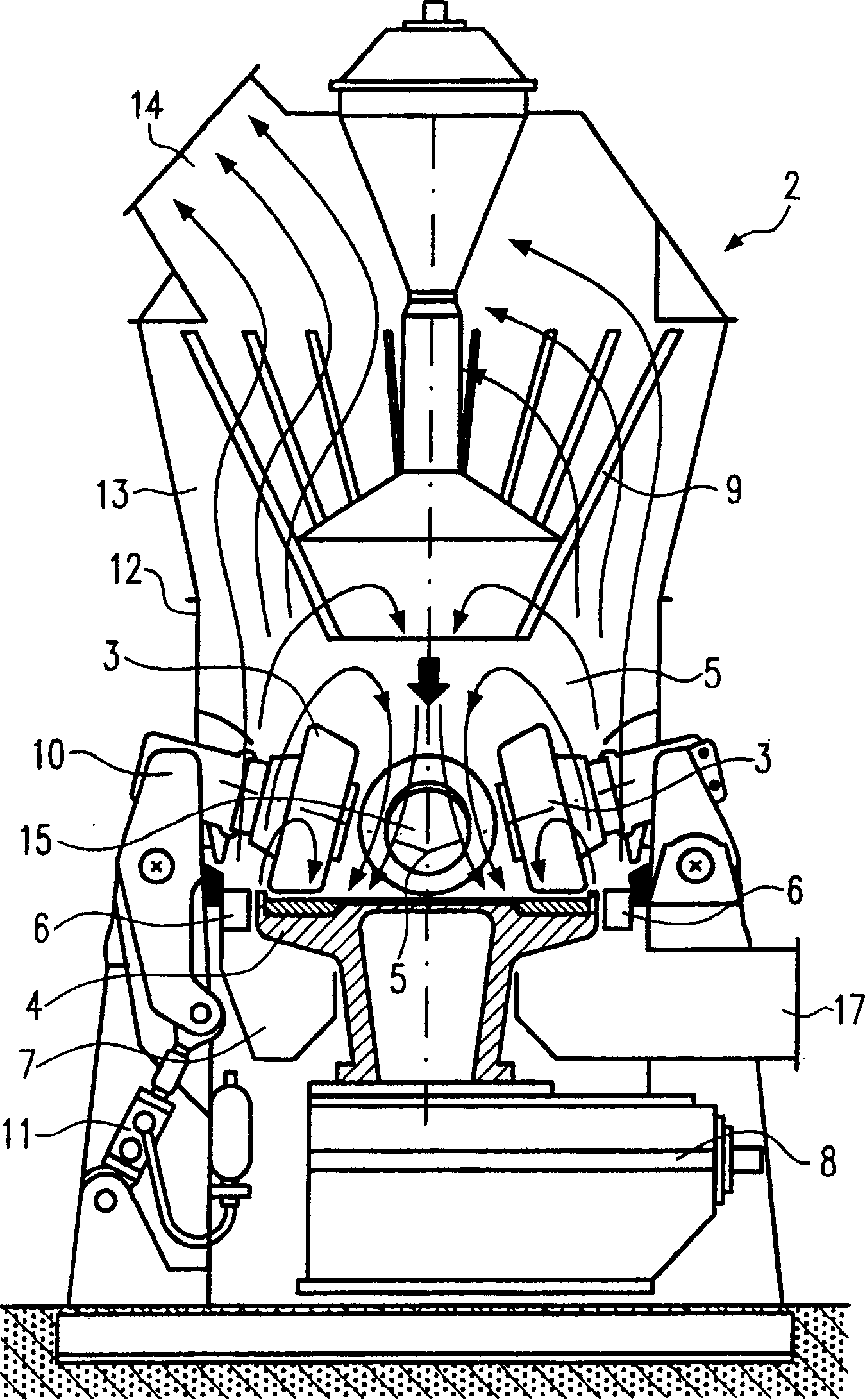

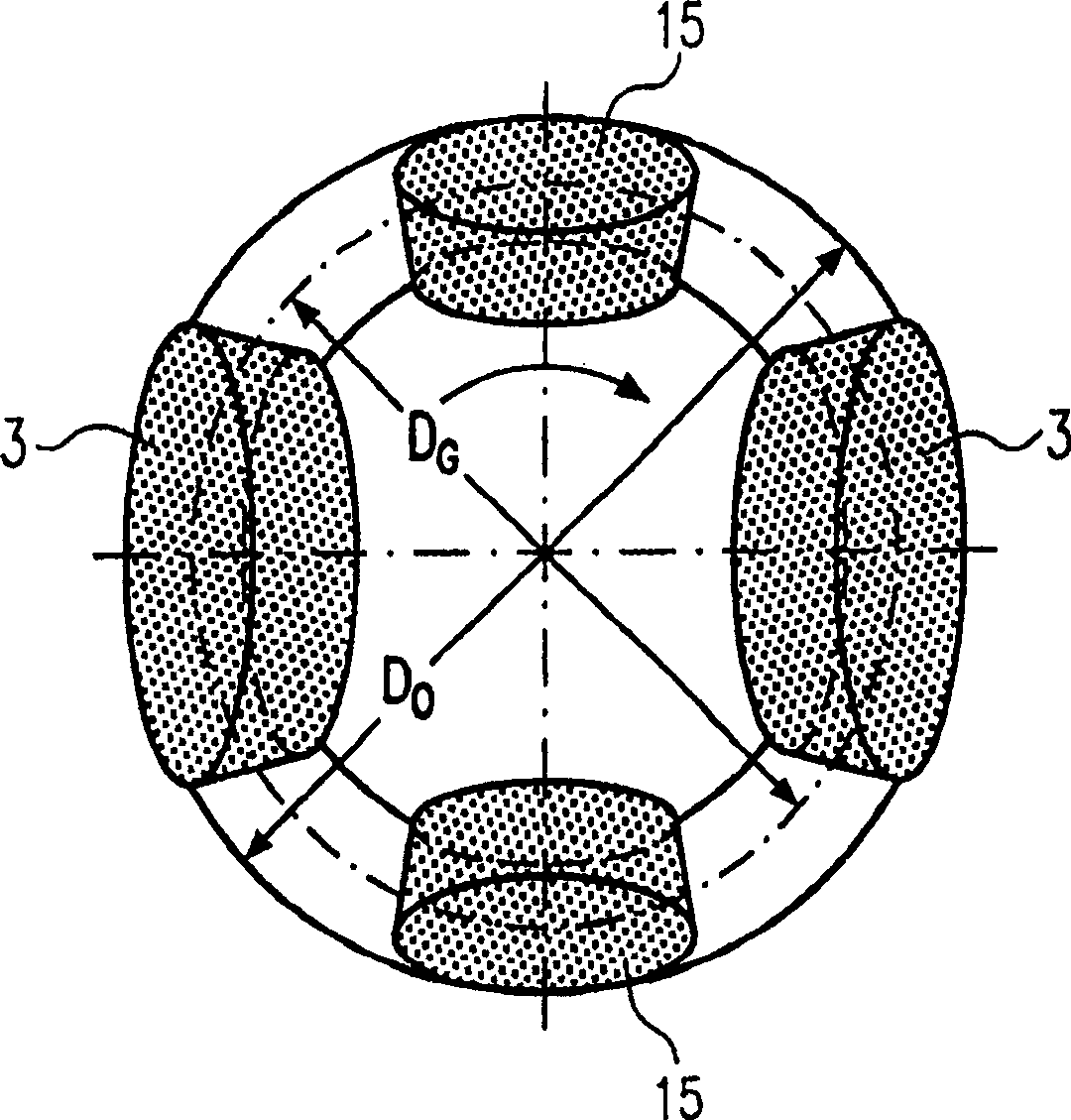

[0036] figure 1 denotes a LOESCHE air-swept roller mill 2 which is especially intended for grinding cement and granulated blast furnace slag and is equipped with two pairs of rollers 3 , 15 . In order not to make the expression too complicated, figure 1 Two grinding rolls 3 are shown, but only one auxiliary roll 15 . but figure 2 Two pairs of rolls are shown, which in any case comprise a grinding roll or master roll 3 and a secondary or slave roll 15 .

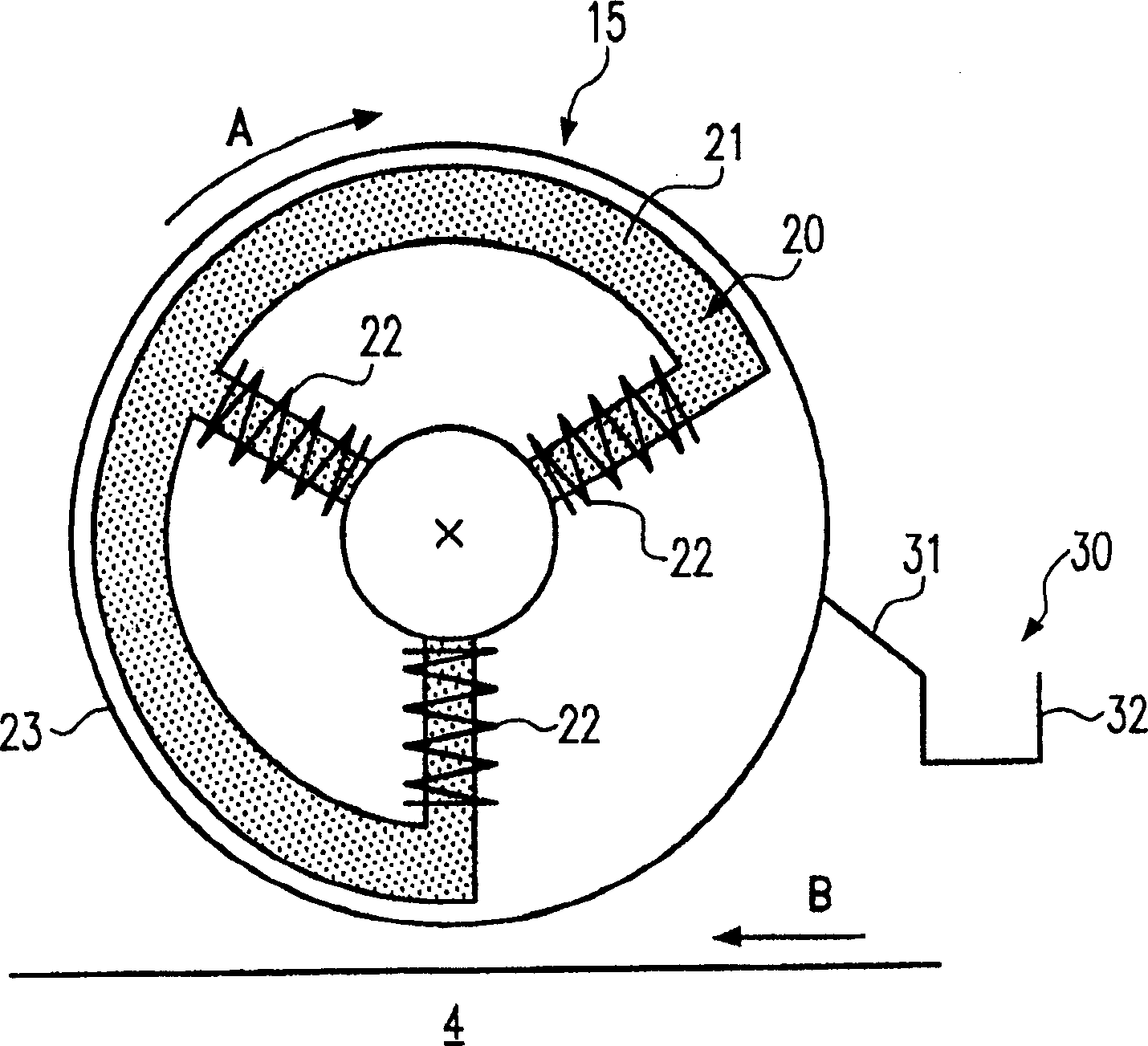

[0037]The master roll 3 and the slave roll 15 roll on an abrasive bed consisting of material in the grinding path of a rotating grinding table 4 . The grinding disc 4 is driven in rotation by a gear 8 and is surrounded by a blade ring 6 , by means of which an air flow, in particular wind, flows from an annular channel 7 into the grinding area 5 . Raw materials such as blast furnace slag or cement slag, a mixture of gypsum and slag are supplied to the wind-swept roller mill through a metering or batching mechanism, a magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com