Making process of creped tobacco sheet

A manufacturing method and sheet technology, applied in the directions of tobacco, tobacco preparation, application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

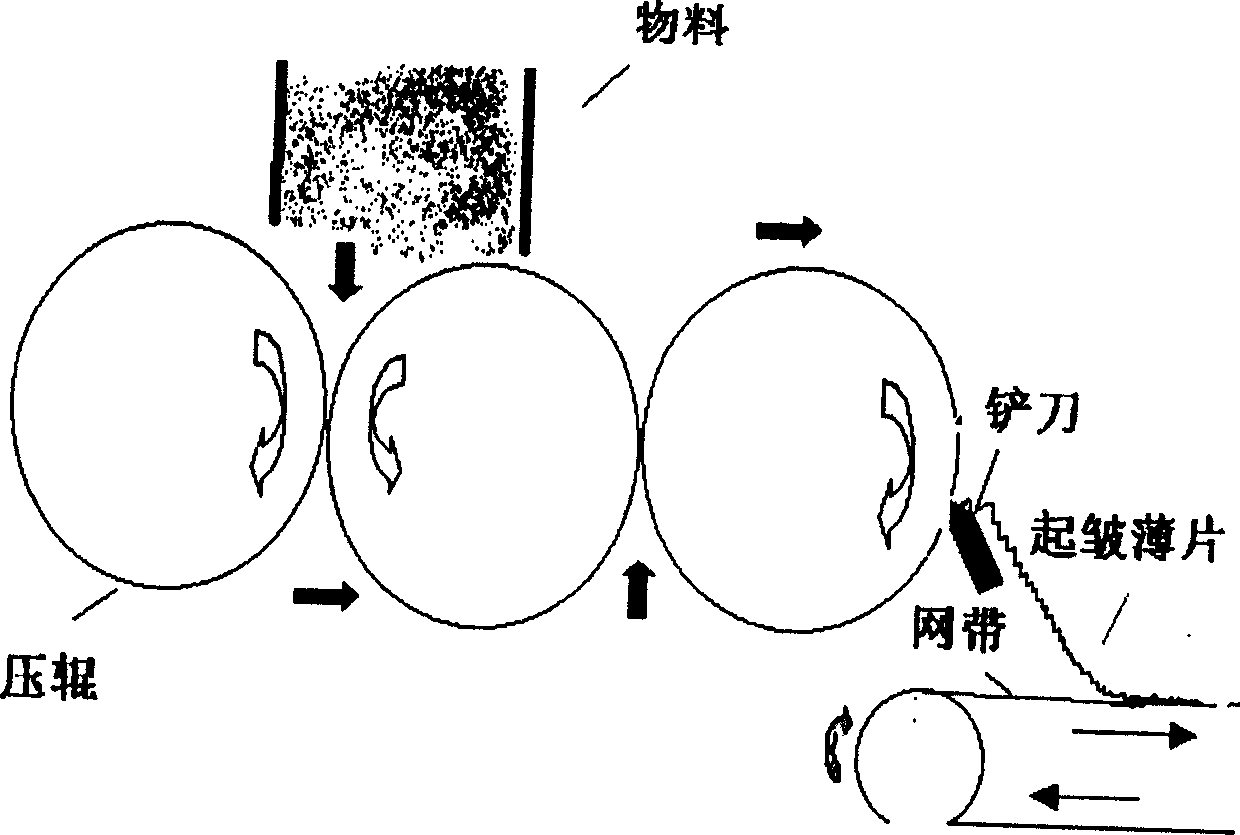

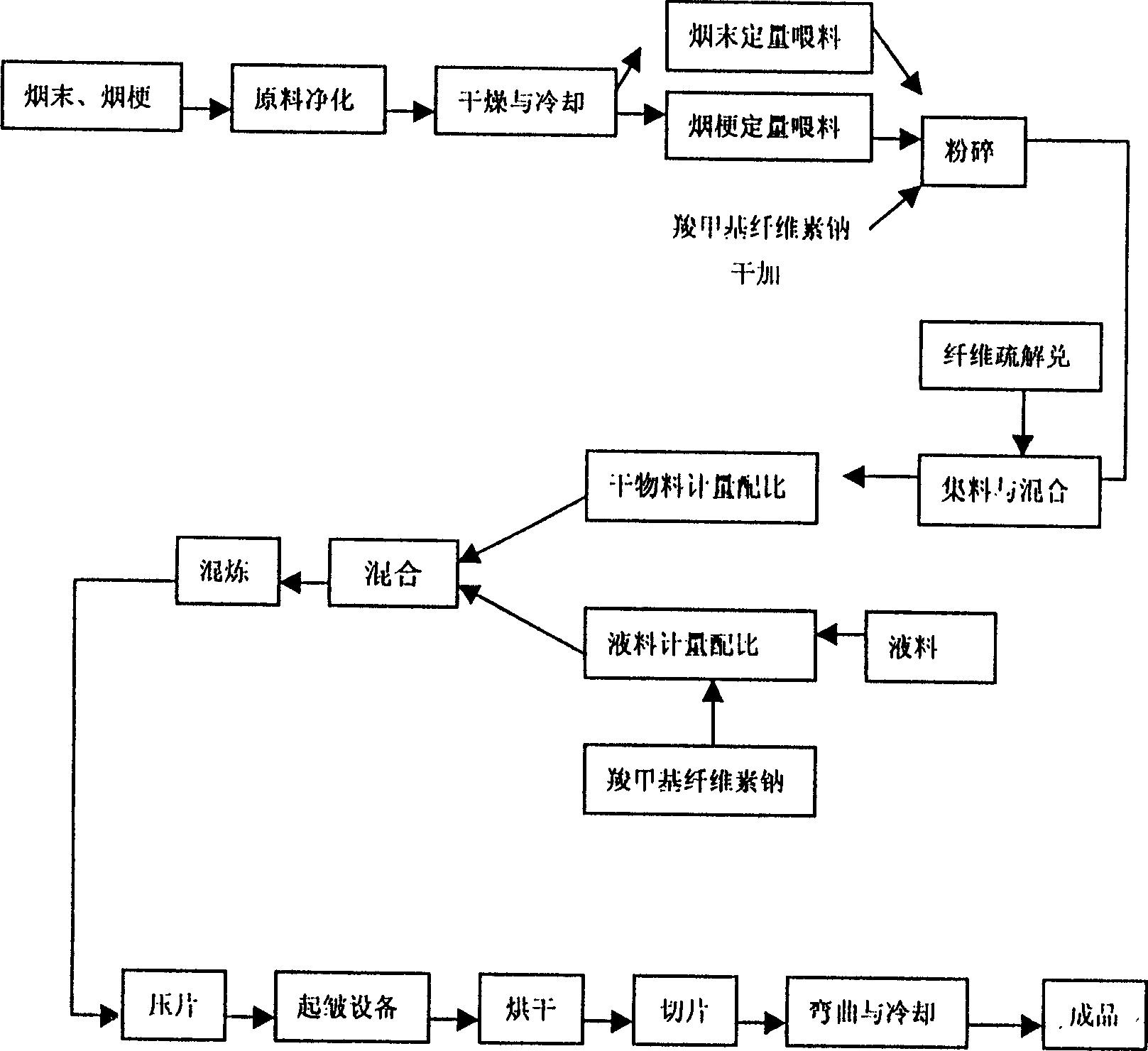

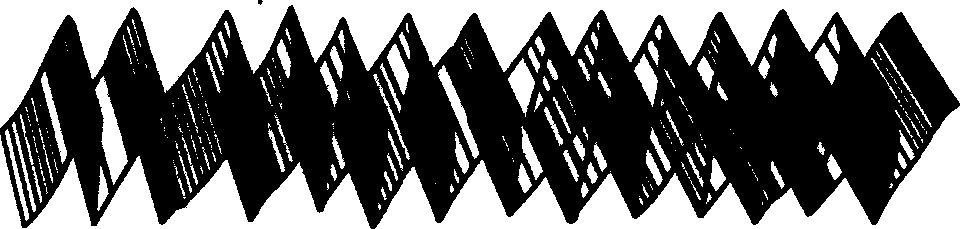

[0023] The wrinkle special agent is made of peanut oil 10‰. Such as figure 2 As shown, first, the length of 3-10cm smoke and figure 1 ). The steam pressure of the corrugation equipment is 0.1mpa, the temperature of the first press roll of the corrugation equipment is controlled at 80°C, the temperature of the second press roll is controlled at 30°C, and the temperature of the third press roll is controlled at 20°C, making continuous The wave crest is 3mm corrugated sheet, and then enters the drying machine to dry at an outlet temperature of 40°C. After being completely cooled, cut into small pieces with a specification of 50×50mm, and finally pack them into boxes.

Embodiment 2

[0025] The wrinkle special agent is made of soybean oil (5‰). Such as figure 2 As shown, first, the length of 3-10cm smoke and figure 1 ). The steam pressure of the corrugation equipment is 0.2mpa, the temperature of the first press roll of the corrugation equipment is controlled at 85°C, the temperature of the second press roll is controlled at 35°C, and the temperature of the third press roll is controlled at 25°C, making continuous The wave crest is 5mm corrugated sheet, and then enters the drying machine to dry at an outlet temperature of 42°C. After being completely cooled, cut into small pieces with a specification of 60×60mm, and finally pack them into boxes.

Embodiment 3

[0027] The wrinkle special agent is made of rapeseed oil 1‰. Such as figure 2 As shown, first, the length of 3-10cm smoke and figure 1 ). The steam pressure of the corrugation equipment is 0.4mpa, the temperature of the first press roll of the corrugation equipment is controlled at 100°C, the temperature of the second press roll is controlled at 40°C, and the temperature of the third press roll is controlled at 30°C, making continuous The wave crest is 7mm corrugated sheet, and then enters the drying machine for drying at an outlet temperature of 44°C. After being completely cooled, cut into small pieces with a specification of 70×70mm, and finally pack them into boxes.

[0028] Adding the flakes prepared in the above examples to cigarettes at a ratio of 5-20% can effectively reduce the tar content in the cigarettes and improve the quality of the cigarettes.

[0029] Compared with the prior art, the present invention has the following advantages and effects:

[0030] 1. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com