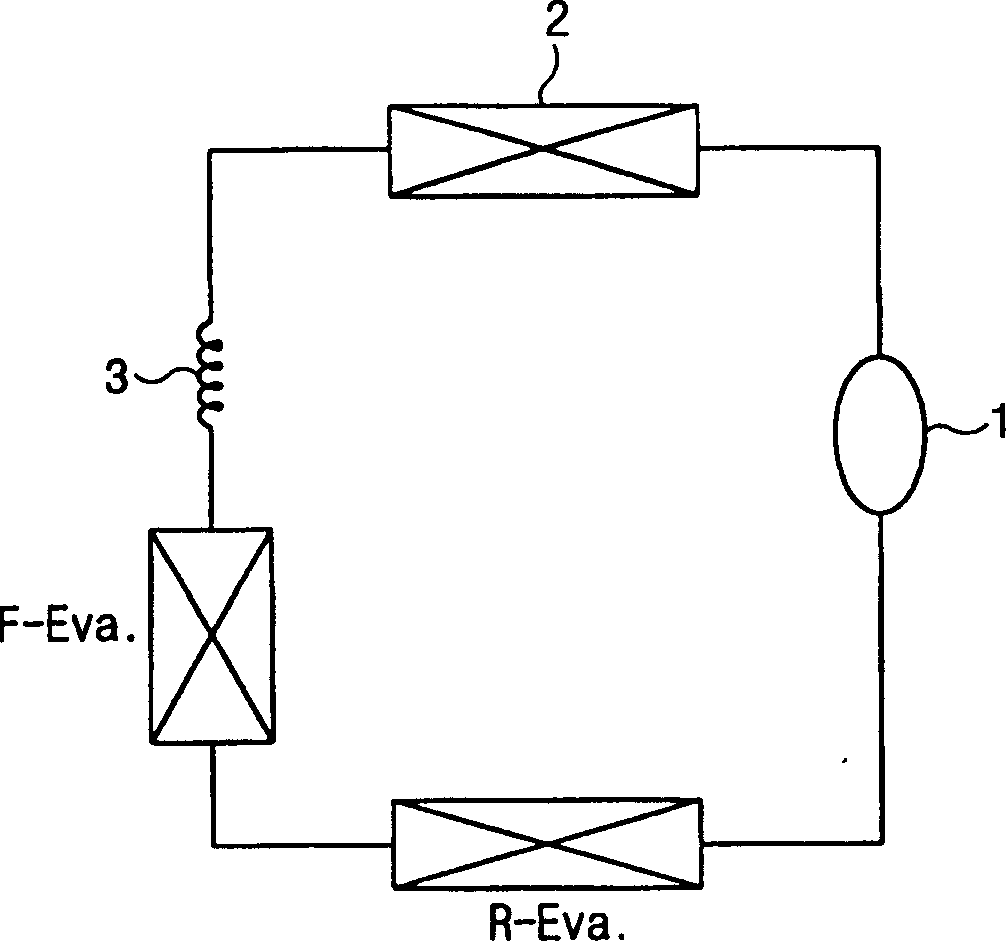

Running control method for clockwise/counter-clockwise rotary compressor of refrigerator

A counterclockwise rotation and operation control technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve problems such as increased power consumption, malfunction of compressors, and reduced operating efficiency of refrigerators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

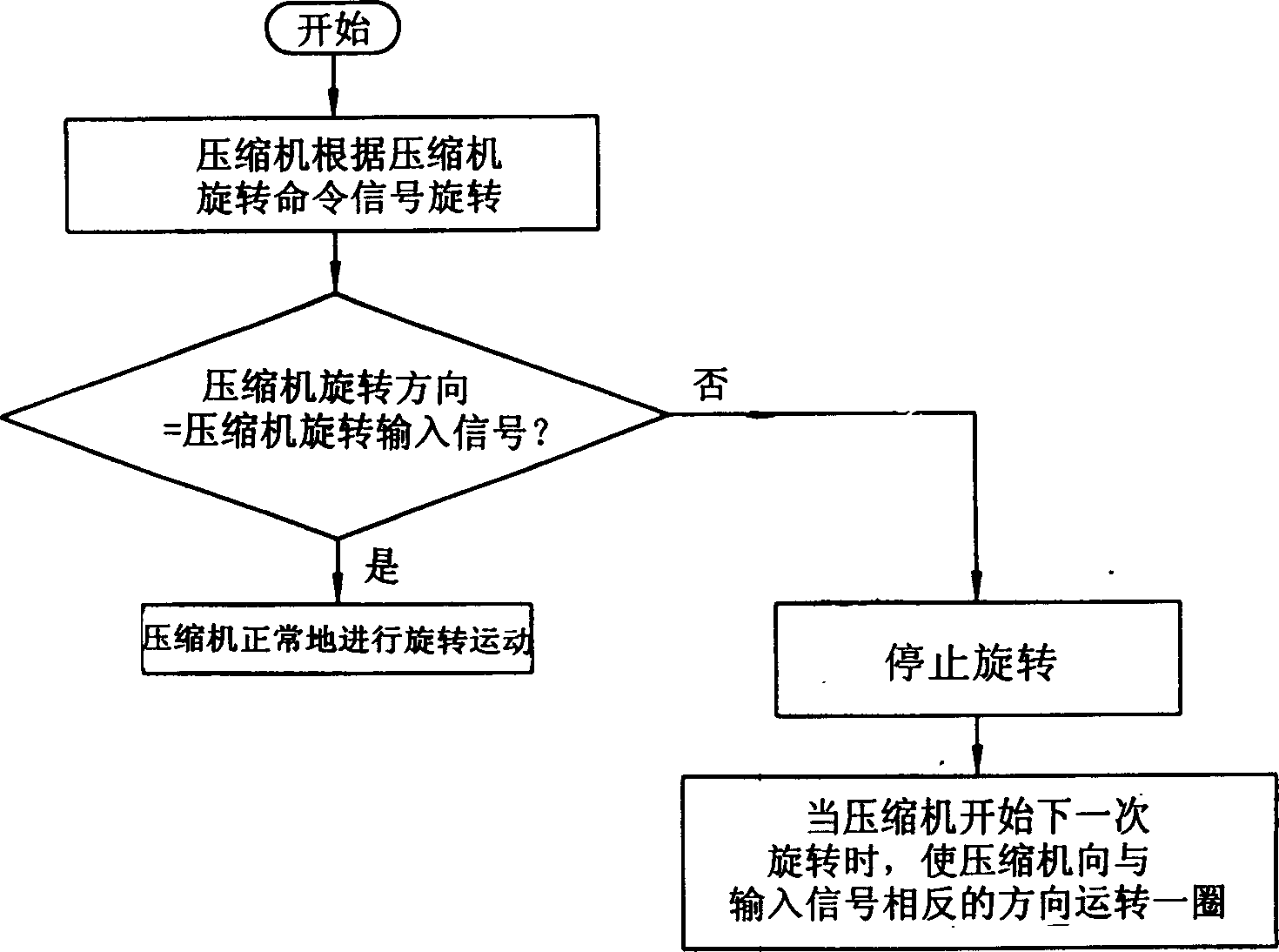

[0022] Hereinafter, examples of the present invention will be described in detail with reference to the accompanying drawings.

[0023] Such as figure 2 As shown, the present invention is to realize the control through the following stages in a refrigerator that maintains the set temperature by rotating the compressor clockwise to increase the cooling force and counterclockwise to decrease the cooling force, that is, the first In this stage, it is necessary to judge whether the current rotation direction of the compressor is consistent with the compressor rotation command signal. If the current rotation direction of the above-mentioned compressor is consistent with the compressor rotation command signal, then the compressor is normally rotated Clockwise / counterclockwise rotation; the second stage, in this stage, if the current rotation direction of the compressor is inconsistent with the compressor rotation command signal, then when the compressor stops rotating and then star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com