Check valve having variable opening-force threshold

A one-way valve, valve seat technology, applied in the direction of lift valve, control valve, valve device, etc., can solve the problem of not having open one-way valve and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the description shown in Figure 1- Figure 12 While presenting preferred and alternative embodiments of the invention, specific terminology has been employed for the sake of clarity. However, the present invention is not limited to the selected specific terms, and it can be understood that each specific technical term includes all technical equivalents that work in a similar manner and achieve similar technical effects.

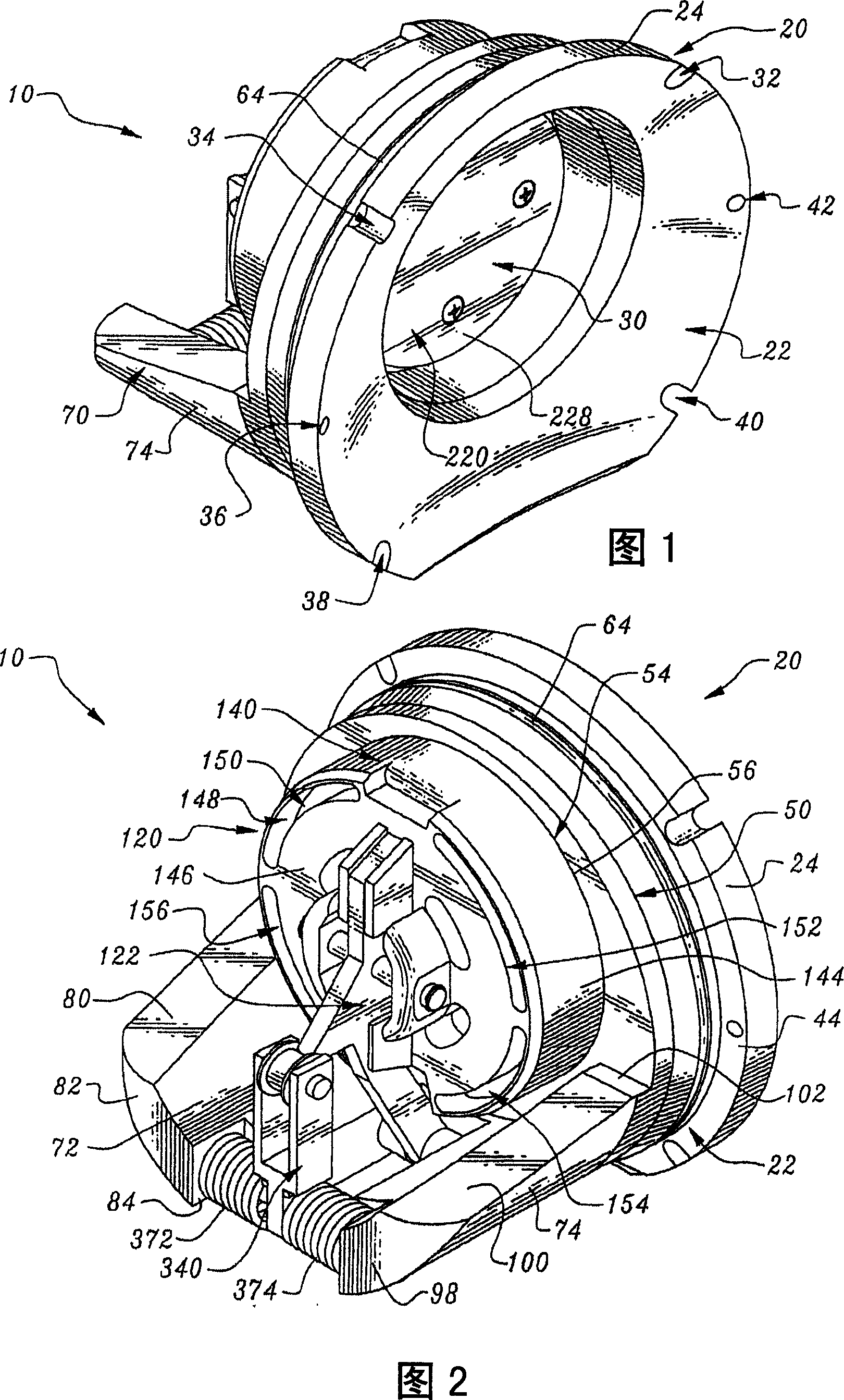

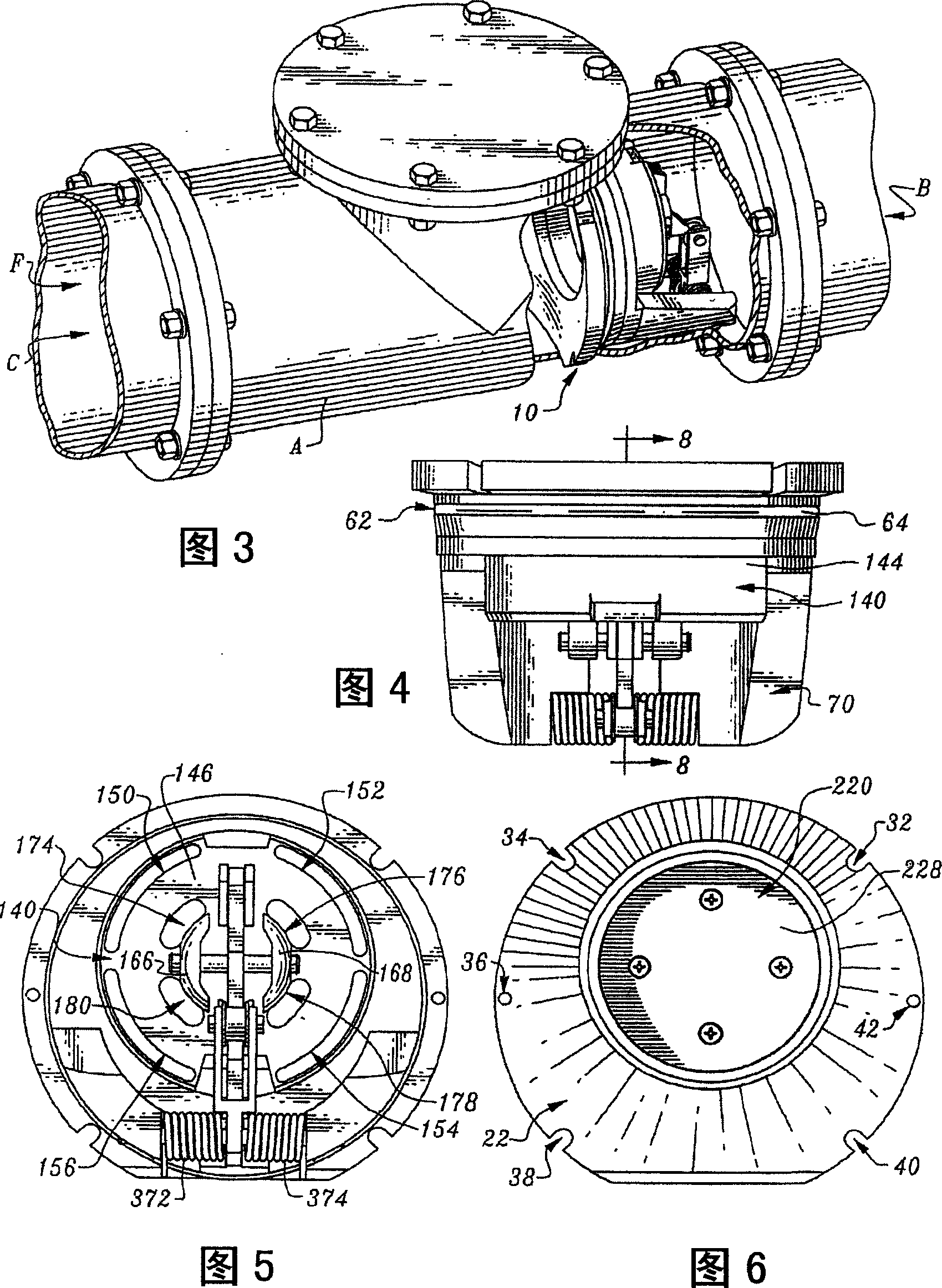

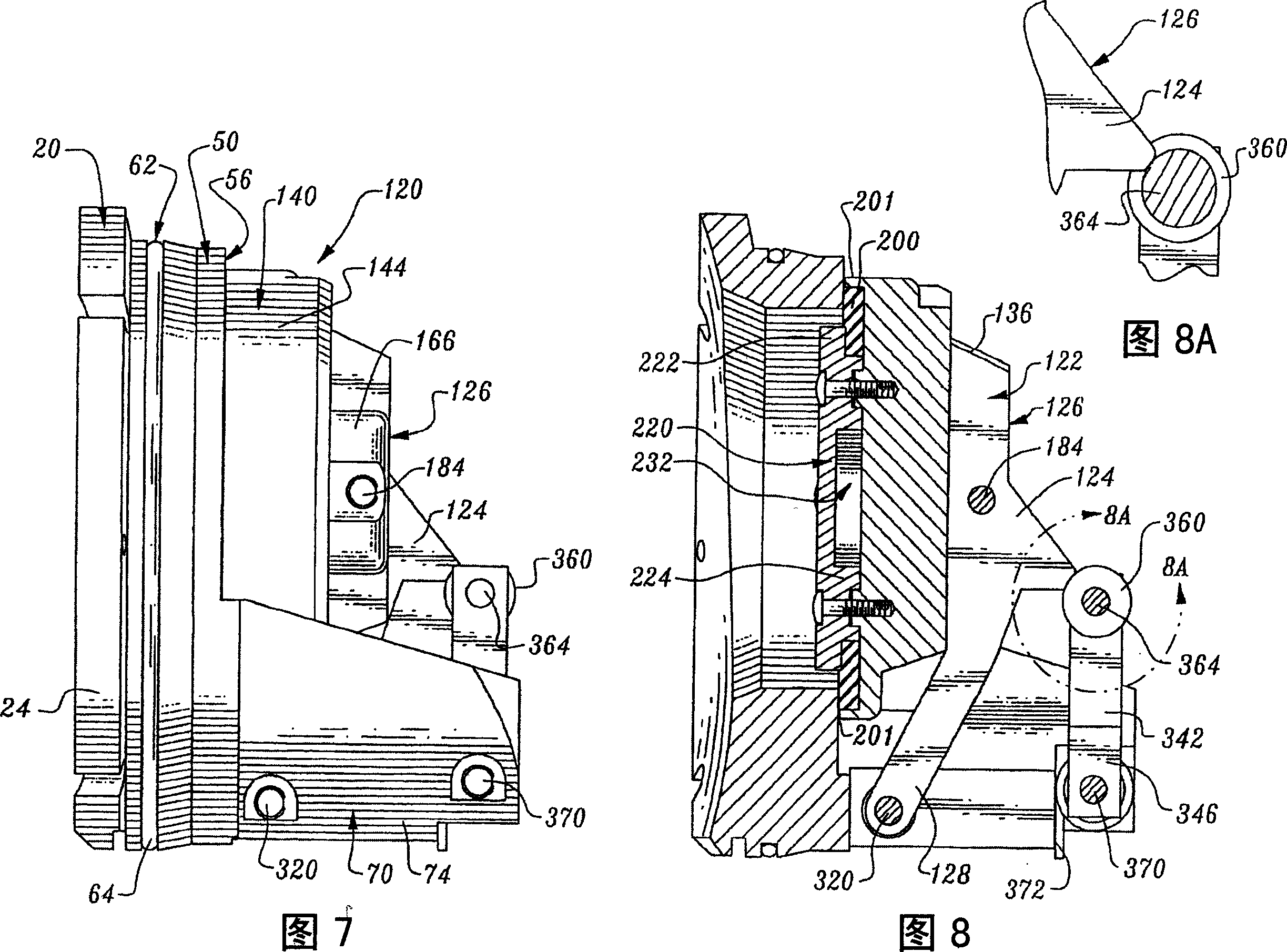

[0025] Referring now to FIGS. 1-2 , the preferred embodiment of the present invention is a one-way valve assembly 10, wherein the one-way valve assembly 10 is basically formed by three relatively movable components, including a mounting part 20, A shutter assembly 120 and a rotatable closure arm assembly 340.

[0026] More specifically, the mounting member 20 is preferably substantially circular and annular in shape and has a mounting portion 22 , a valve seat portion 50 and a valve bracket 70 . Seat portion 50 preferably has a smaller diameter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com