Ceramic sample box fused metal sample sampler

A molten metal and sampler technology, applied in the direction of sampling devices, etc., can solve the problems of extremely strict composition control requirements, deviation of sampling composition, and lack of versatility in sampling of metal sample boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

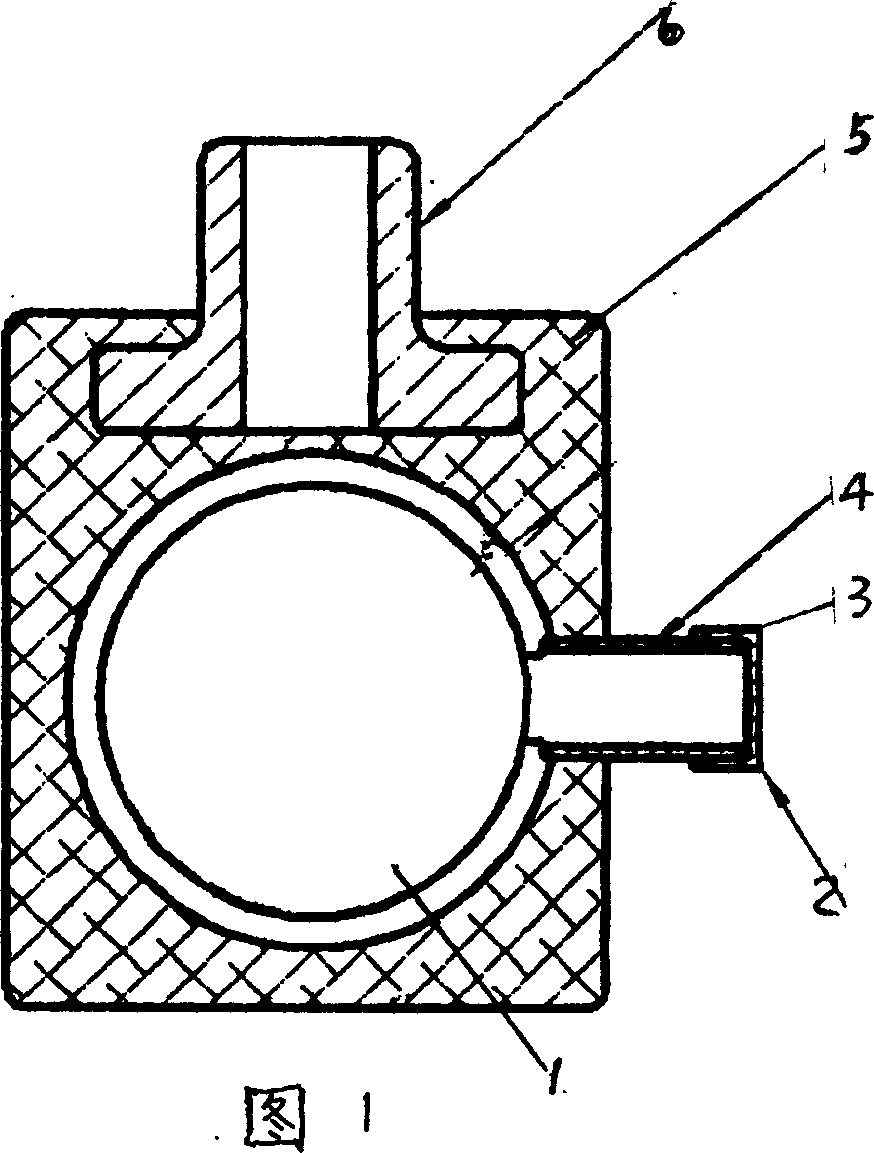

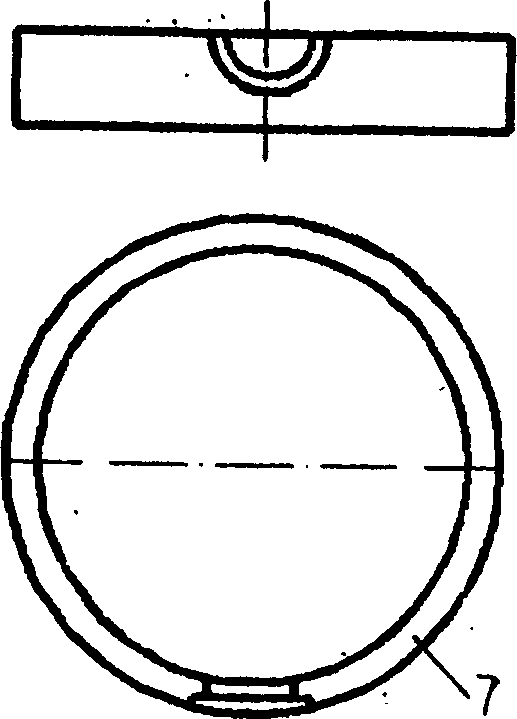

[0026] Embodiment 2, round element sample ceramic sample box sampler

[0027] a. Disc-like ceramic sample box, cordierite, Al 2 o 3 0wt%, MgO10wt%, SiO 2 60wt%, the porosity of the sample box is 20-30%.

[0028] b. Drain tube: cordierite ceramic guide tube

[0029] c. Consolidation component: resin sand mold.

Embodiment 3

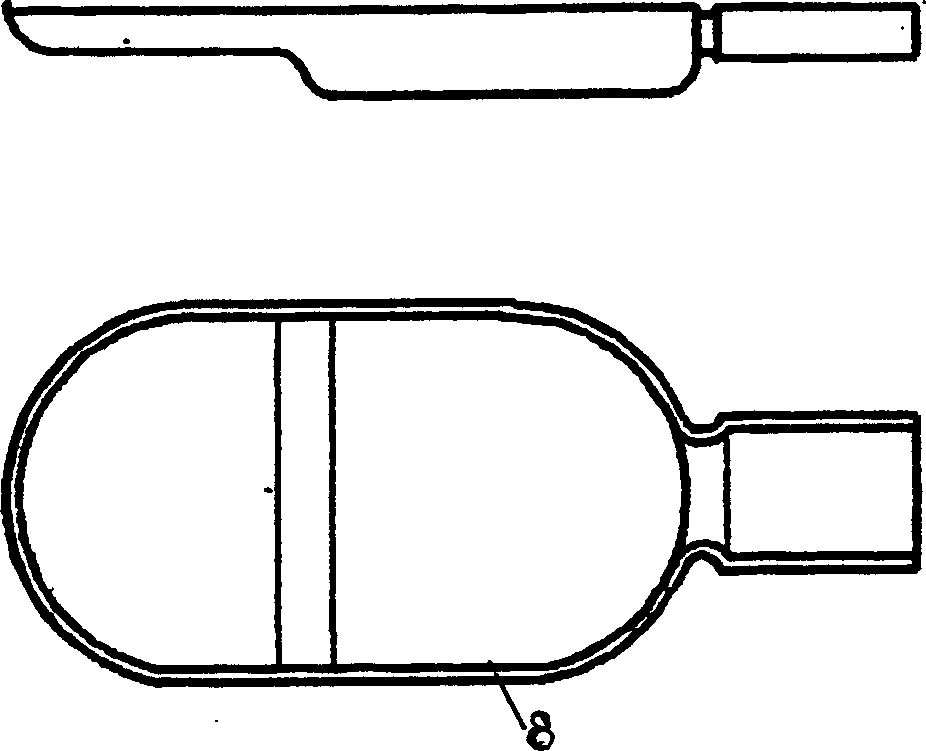

[0030] Embodiment 3, racket sample ceramic sample box sampler

[0031] a. Racquet-like ceramic sample box, made of alumina, Al 2 o 3 90wt%, SiO 2 And / or MgO10wt%, porosity 20-30%.

[0032] b. Drain tube: Al 2 o 3 Ceramic tube

[0033] c. Consolidation component: resin sand mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com