Middle pressure test technology and device for widebore pipeline construction

A large-diameter pipeline and pressure testing technology, which is applied in the measurement of hydraulic/pneumatic force, liquid-tightness measurement using liquid/vacuum degree, etc., can solve the problems of stopping construction and affecting the progress of the project, so as to speed up the progress of project construction, The effect of reducing installation and dismantling workload and reducing trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

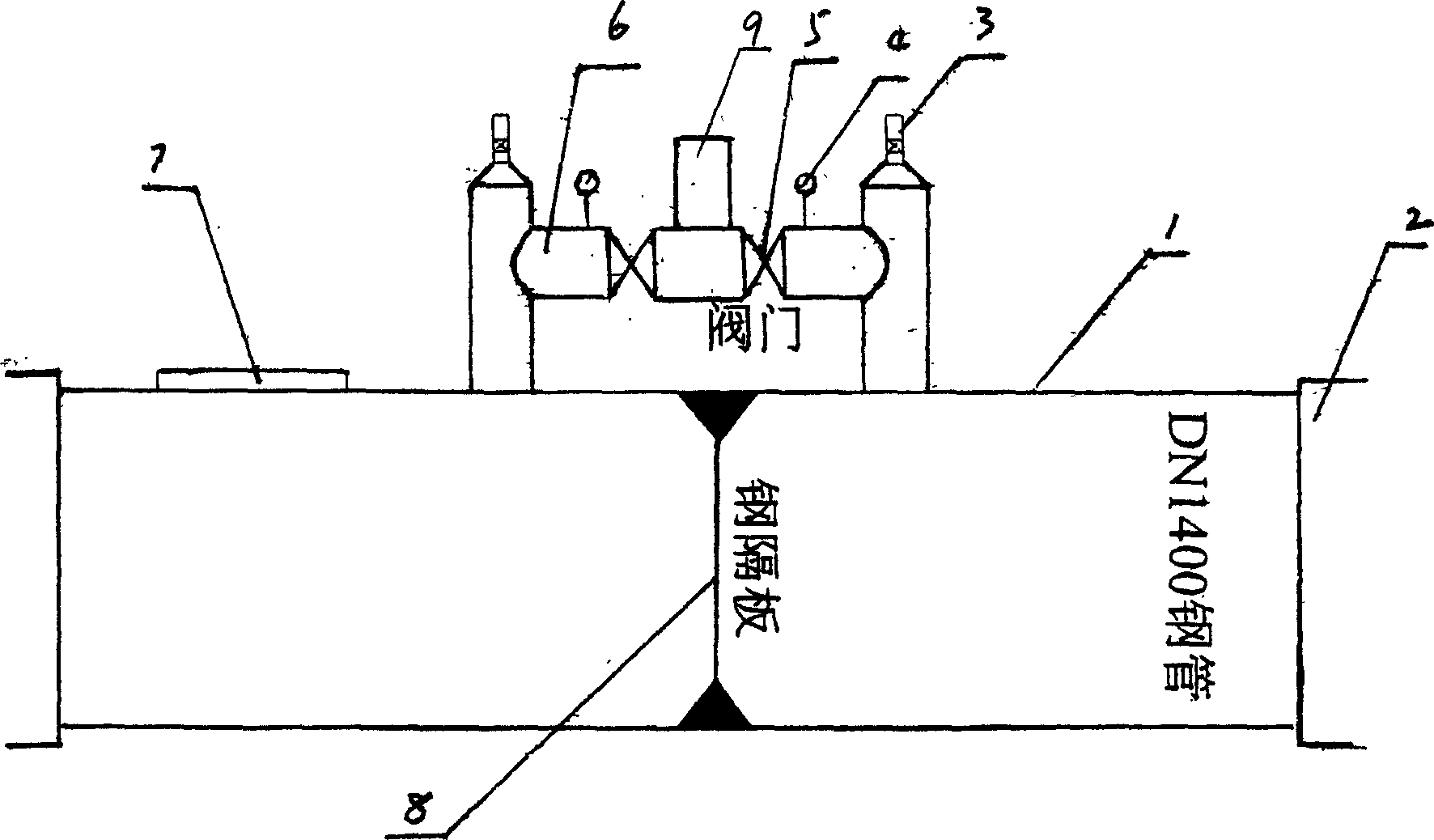

[0018] refer to figure 2 , the intermediate pressure test pipe of the present invention comprises a steel pipe (1), the two ends of the steel pipe (1) are welded together with the conversion joint (2), and a steel partition (8) is welded at the center of the steel pipe (1), and the steel pipe is divided into For two parts that are not connected, an H-shaped bypass pipe (6) is installed on the steel pipe, and 2 bypass valves (5), 2 pressure gauges (4), and 2 bypass valves (5) are symmetrically installed on the bypass pipe (6). An exhaust valve (3) and a water injection pipe (9) also leave a manhole (8) for entering and leaving people on the steel pipe (1).

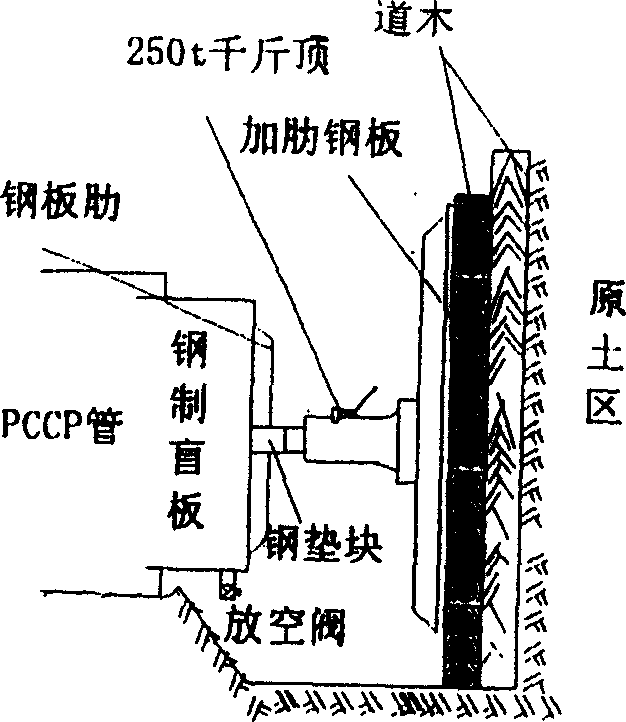

[0019] In this example, the first phase of the water supply project in Changzhou area was selected, the whole line is 36Km, and the DN1400 large-diameter steel cylinder prestressed concrete pipe with an effective length of 5m and a weight of 8t per section is used, referred to as PCCP pipe, so the pressure test steel pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com